Test methods and requirements for electric anchor windlass

The experiment of electric anchor windlass should be carried out in the "Test Methods for Electric Windlasses and Anchor Winches" CB/T 3242-1995. If there are any class certificate requirements, it should comply with the rules or standards of the corresponding classification society. The test items include the No-load test, Workload test, Overload pull test, Holding load test, Motor brake test, Emergency stop test etc.

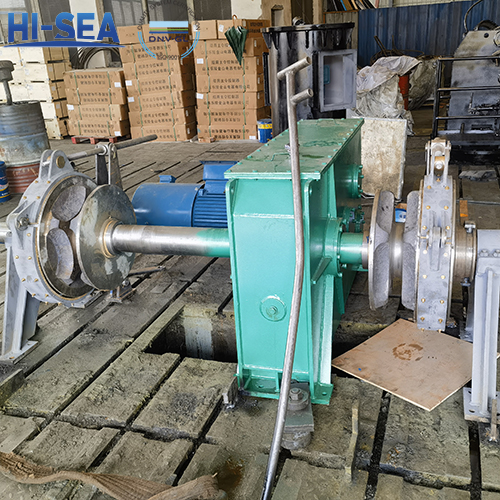

Overview

Electric windlass is a device used for ship anchoring operations, and its experimental methods and requirements can be carried out according to the following steps and standards:

1.1 No-load test

1.1.1 Test method

a) The motor runs continuously without load at the rated working speed for 30 minutes, with each turn for 15 minutes.

b) After the above test is completed, the motor should run at other speeds as soon as possible, with each turn for 5 minutes.

1.1.2 Requirements

a) Check if the anchor machine is operating normally and there should be no abnormal vibration or noise.

b) Check the gearbox to ensure that there is no oil leakage or leakage.

c) The action of the electric motor brake should be sensitive and reliable.

d) Measure and record the no-load current, speed, and input power voltage of the motor at the rated operating gear.

1.2 Workload test

The load test should be conducted after the problems found in the no-load test are eliminated.

1.2.1 Test procedure

A Windlass

a) Engage the anchor chain with the Gypsy and engage the sprocket(/gypsy) clutch.

b) Use 50%, 75%, and 100% of the working load of the windlass as the loading load, and adjust the loading weight one by one.

c) The motor lifts and loads the weight block within a distance of no less than 8 meters at rated working speed, and repeats twice at 50% and 75% loading levels; At 100% loading level, continuously raise and lower for a total of 30 minutes. During the test, if the temperature rise of the motor exceeds the allowable value, it should be cooled before proceeding.

d) During the prototype test, perform an emergency shutdown test once during the 100% load level descent, that is, press the emergency button to cut off the power supply.

B Warping head

Release the clutch of the anchor chain wheel, tighten the brake of the anchor chain wheel, and wind the cable around the warping head for 4-5 turns to load the mooring load. Start the motor to lift and load the weight twice within a distance of no less than 8 meters at the rated working speed.

1.2.2 Requirements

a) Check if the windlass operates normally and there should be no abnormal vibration or noise. The clutch should be flexible and lightweight.

b) Check the gearbox to ensure that there is no oil leakage

c) Check whether the engagement between the anchor chain wheel and the anchor chain is good, and there should be no chain jumping phenomenon.

d) During the emergency shutdown test, the windlass should be immediately stopped to check the reliability of the emergency shutdown.

e) Check the working current, speed, power and voltage of the motor at all levels of load.

f) Measure the time it takes for the anchor chain (cable) to pass over 5m at 100% loading level, and measure the lifting speed of the anchor machine and mooring line.

g) Measure the oil temperature and shaft bearing temperature of the gearbox.

1.3 Overload pull test

1.3.1 Test method

a) Adjust the loading weight with 150% of the working load of the anchor machine as the loading load.

b) Lift and load the heavy block within a distance of no less than 8 meters, and continuously work at low speed for 2 minutes. At this time, the speed is not measured.

1.3.2 Requirements

a) The inspection items are the same as items a), b), and c) in 1.2.2 of this section.

b) Measure the overload current of the motor.

1.4 Motor brake test

1.4.1 Test method

a) Adjust the loading weight with 150% of the working load of the anchor machine as the loading load.

b) Use the low-speed gear of the electric motor to lift the loading weight to over 2m, then cut off the power and brake, and conduct two tests.

1.4.2 Requirements

a) Check the reliability of the motor brake operation.

b) Measure the braking slip of the loaded weight.

1.5 Manual brake test for anchor chain wheel

a) Raise the working load by about 8m by 60% of the hanging weight, release the clutch, and operate the brake handle to brake 1-2 times before the weight falls to the ground.

b) The operation of the manual brake device should be flexible, lightweight, safe, and reliable.

1.6 Holding load test

This experiment can be verified by the calculation sheet for supporting load capacity calculation results. This test may not be conducted on-site.

1.7 Overhaul

a)Check the contact between the spindle and the bearing.

b) Check the engagement of the open-gear pair

c) Check the contact between the brake band and the brake wheel.

The above inspection shall not have cracks, burns, or other damages that hinder actual use. If no abnormalities are found during the test, other parts may not be disassembled for inspection.

1.8 Emergency stop test

When lifting and lowering the working load continuously at nominal speed, an emergency stop test should be carried out to check the reliability of the emergency stop.

1.9 Controlled braking test (take the higher torque in anchoring and mooring)

The electric windlass should lift 1.5 times the working load by more than 2m in the low-speed gear of the motor, cut off the power supply and the control brake should immediately brake the motor without slippage.

The hydraulic windlass should lift 1.3 times the working load by more than 2m, then operate the hydraulic motor control handle to the neutral position, the control brake should brake the hydraulic motor, and the load slip should not exceed 1m/min

For more marine anchor windlass information, kindly please click here.