Marine Hydraulic Windlass

A hydraulic windlass is a piece of machinery commonly used on ships to raise and lower anchors. It's a vital component for maritime vessels, especially large ones, as it helps in anchoring operations. It is powered by a hydraulic motor. The hydraulic system provides the power necessary to operate the windlass efficiently, allowing it to handle heavy anchor chains and anchors with ease.

The marine hydraulic windlass has large torque capacities because the hydraulic motor system can work at very low speeds. It is better and more flexible than an electric motor.

Overview

The basic components of a hydraulic windlass include a hydraulic motor, a gearbox, the gypsy wheel around which the anchor chain is wound, brake and clutch. The hydraulic motor converts hydraulic pressure into rotational mechanical motion, which drives the gearbox. The gearbox, in turn, adjusts the speed of the motor to match the requirements of the windlass. The brake and clutch will be equipped to control the operation of gypsy wheel and other parts.

The hydraulic windlass favored for its power and reliability, making it suitable for handling heavy anchors and chains in various weather and sea conditions. Additionally, it offers precise control over anchor deployment and retrieval, crucial for safe navigation and docking.

Features

Driven by the hydraulic motor

Gypsy wheel: single, double, or other type

Can be equipped with drum and warping head as your requirements

Brake: manually or hydraulically

Clutch: manually or hydraulically

Compact structure, small volume

Steady operation, high durability and reliability

Class certificates: CCS, RS, BV...

It can be customized according to your needs.

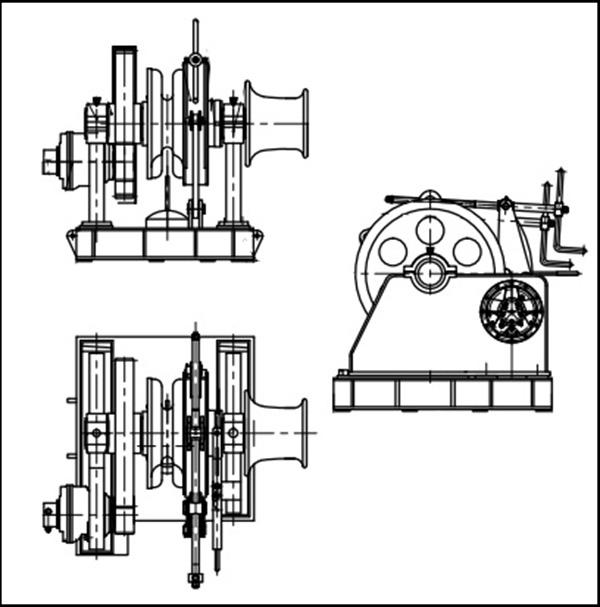

Drawing of Marine Hydraulic Windlass

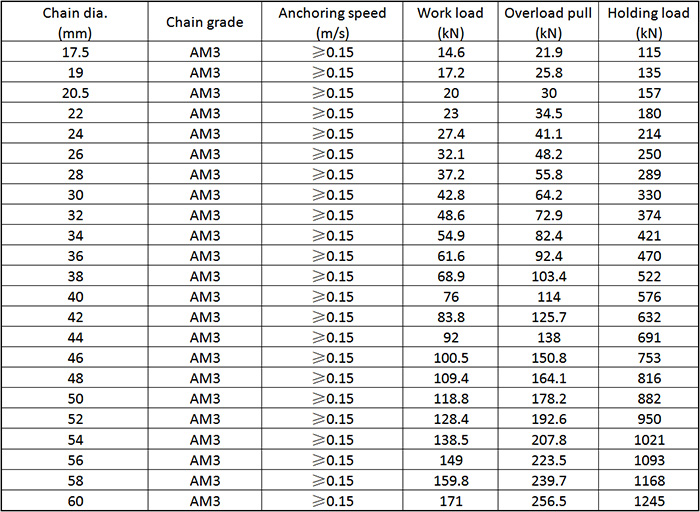

Main Technical Parameter (only for reference)