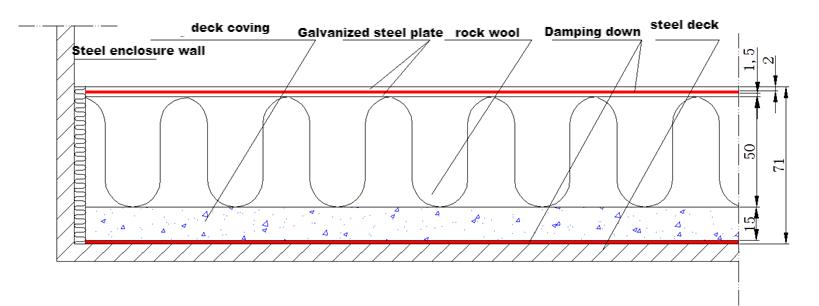

Structure of Floating Floor

Floating floor refers to a composite deck structure in which insulation material or other elastic body is directly laid on the steel deck as the base material and combined with the bulkhead, which has the functions of vibration reduction, noise reduction and sound absorption.

Overview

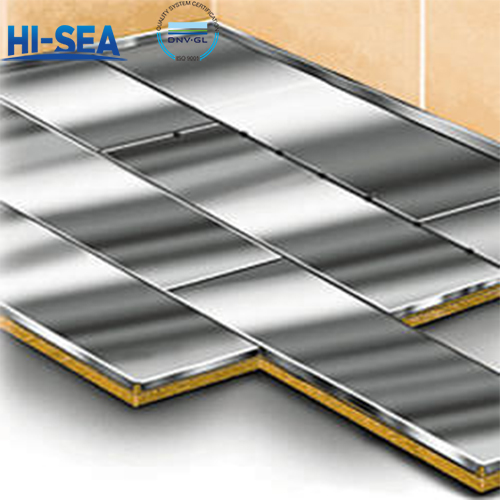

A Marine Floating Floor is a specialized resilient deck construction designed to be installed over the ship's primary steel deck. It mechanically decouples the finished cabin floor from the vibrating hull structure, thereby dramatically reducing the transmission of structure-borne noise and vibration into living and working spaces. This system is essential for meeting crew comfort standards and is often mandated in cabins, hospitals, and other noise-sensitive areas.

Product Composition

The floating floor is composed of 50mm lightweight fireproof insulation material rock wool as the bottom layer, and 3mm thick galvanized steel plate (1mm thick damping glue is used in the middle) as a floating deck structure. It is mainly used in the cabins of ships (with A60 fire protection requirements) and has excellent vibration reduction, noise reduction, sound insulation and heat insulation functions.

Product Characteristics

It has excellent vibration reduction, noise reduction, sound insulation, heat insulation and sound absorption functions. After testing, the sound insulation value reaches 62db;

Light weight, effectively reducing the empty ship tonnage;

The overall thickness of the product is thin, which effectively increases the interior space;

The fire resistance level reaches A60;

It can effectively improve the comfort of cabin personnel.

Structure of Floating Floor