Rod Horizontal Expansion Joint

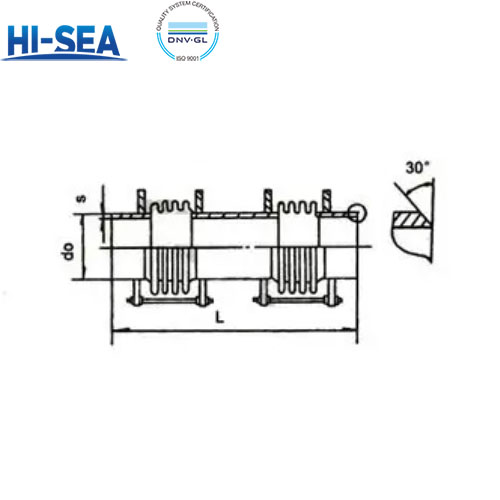

Rod type horizontal expansion joint is a device used to compensate the transverse displacement of piping system, which is mainly composed of receiver, two bellows and large tie rod and other components. It can absorb the lateral displacement of piping system in any plane and has the ability to withstand internal pressure thrust.

Overview

Features

Bellows design: The bellows adopts multi-layer design with good elasticity and flexibility, which can play an effective absorbing and buffering role when the piping system is displaced or deformed.

Large tie rod design: By fixing the large tie rod, the axial displacement can be effectively limited to ensure that the compensator has stable structural strength and long-lasting service life when absorbing lateral displacement.

Advantages

(1) Absorption of pipeline displacement: rod horizontal expansion joint can flexibly cope with the transverse displacement of the pipeline, especially suitable for thermal pipelines, water supply and heating systems and petrochemical pipelines, etc., to ensure the normal operation of the pipeline at different temperatures.

(2) Sturdy and durable structure: the bellows part is made of high-quality materials with good corrosion resistance and long service life, which is suitable for all kinds of complex working environments.

(3) Reducing pipe vibration: through the design of large tie rods, pipe displacement can be effectively controlled, reducing pipe vibration and lowering the risk of fatigue damage in the long-term operation of the pipeline.

(4) Adaptation to complex working conditions: in high temperature, low temperature, pressure changes and other harsh conditions, rod horizontal expansion joint can still operate normally, suitable for long-distance pipeline displacement compensation, especially in the complex terrain or need to tolerate a large lateral displacement of the pipeline environment plays an important role.

(5) Convenient installation and maintenance: compact structure, easy to install, relatively low maintenance costs, can extend the service life of the pipeline system.

Nominal Path DN mm | Bellows | Y0---Horizontal compensation (mm) | KY0---Lateral stiffness (N/mm) | Radial | Product Type | |||||||||||

Effective Area A cm2 | Wave Number n | Total length L mm | ||||||||||||||

1000 | 1500 | 2000 | 2500 | 3000 | 3500 | |||||||||||

Y0 | KY0 | Y0 | KY0 | Y0 | KY0 | Y0 | KY0 | Y0 | KY0 | Y0 | KY0 | |||||

Design pressure Pd=0.25MPa(2.5kgf/cm2) Fatigue life[N]=1000 Design temperatuure t=20℃ | ||||||||||||||||

100 | 153 | 8 | 125 | 4.1 | 261 | 1.1 | 398 | 0.48 | 535 | 0.27 | 320x380 | ADH | ||||

150 | 297 | 92 | 10.9 | 191 | 2.9 | 291 | 1.3 | 392 | 0.72 | 350x410 | ||||||

200 | 527 | 111 | 15 | 249 | 3.7 | 390 | 1.6 | 531 | 0.91 | 500x560 | ||||||

250 | 769 | 204 | 6.4 | 319 | 2.8 | 435 | 1.6 | 551 | 1 | 540x600 | ||||||

300 | 1064 | 209 | 8.1 | 332 | 3.5 | 456 | 1.9 | 581 | 1.2 | 570x630 | ||||||

350 | 1257 | 170 | 13 | 283 | 5.1 | 397 | 2.8 | 511 | 1.7 | 670x730 | ||||||

400 | 1605 | 149 | 18 | 248 | 7.3 | 348 | 3.9 | 448 | 2.4 | 700x760 | ||||||

450 | 1987 | 132 | 25 | 219 | 9.9 | 307 | 5.3 | 396 | 3.3 | 770x850 | ||||||

500 | 2411 | 117 | 33 | 195 | 13 | 274 | 7.1 | 353 | 4.4 | 810x890 | ||||||

600 | 3452 | 107 | 65 | 206 | 22 | 308 | 11 | 412 | 6.3 | 517 | 4.2 | 900x980 | ||||

700 | 4742 | 95 | 96 | 184 | 32 | 275 | 16 | 368 | 9.3 | 461 | 6.2 | 1150 | ||||

800 | 6041 | 85 | 131 | 164 | 44 | 245 | 21 | 328 | 13 | 411 | 8.4 | 1250 | ||||

900 | 7497 | 76 | 174 | 147 | 58 | 220 | 29 | 294 | 17 | 369 | 11 | 1350 | ||||

1000 | 9287 | 72 | 239 | 140 | 80 | 210 | 39 | 280 | 23 | 351 | 15 | 1480 | ||||

1500 | 2000 | 2500 | 3000 | 3500 | 4000 | |||||||||||

1100 | 11074 | 66 | 306 | 127 | 102 | 190 | 50 | 254 | 30 | 318 | 20 | 383 | 14 | 1580 | ||

1200 | 13017 | 60 | 387 | 115 | 129 | 172 | 63 | 230 | 38 | 289 | 25 | 347 | 18 | 1680 | ||

1300 | 15118 | 55 | 481 | 106 | 160 | 158 | 79 | 212 | 47 | 265 | 31 | 319 | 22 | 1780 | ||

1400 | 17376 | 50 | 590 | 97 | 197 | 145 | 97 | 194 | 57 | 243 | 38 | 293 | 27 | 1880 | ||

1500 | 19791 | 47 | 713 | 90 | 238 | 135 | 117 | 180 | 69 | 226 | 45 | 271 | 32 | 1980 | ||

1600 | 22362 | 43 | 853 | 83 | 284 | 125 | 140 | 167 | 83 | 209 | 55 | 251 | 39 | 2080 | ||

1700 | 25092 | 40 | 1010 | 78 | 336 | 116 | 166 | 156 | 98 | 195 | 65 | 234 | 46 | 2180 | ||

1800 | 27978 | 38 | 1185 | 73 | 395 | 110 | 194 | 146 | 115 | 184 | 76 | 221 | 54 | 2280 | ||

1900 | 31021 | 36 | 1379 | 69 | 459 | 103 | 226 | 138 | 134 | 173 | 88 | 208 | 63 | 2380 | ||

2000 | 34735 | 67 | 759 | 106 | 343 | 147 | 194 | 189 | 125 | 230 | 87 | 2510 | ||||

2200 | 41656 | 60 | 991 | 96 | 448 | 133 | 253 | 170 | 163 | 207 | 113 | 2710 | ||||

2400 | 49205 | 55 | 1266 | 87 | 572 | 121 | 324 | 155 | 208 | 189 | 144 | 2910 | ||||

2500 | 53216 | 52 | 1423 | 84 | 643 | 116 | 364 | 148 | 233 | 181 | 162 | 3010 | ||||

2600 | 57383 | 50 | 1592 | 80 | 719 | 111 | 407 | 142 | 261 | 173 | 182 | 3110 | ||||

2800 | 66189 | 47 | 1964 | 74 | 887 | 103 | 502 | 132 | 322 | 161 | 224 | 3310 | ||||

3000 | 75623 | 43 | 2395 | 69 | 1082 | 96 | 612 | 123 | 393 | 150 | 273 | 3510 | ||||