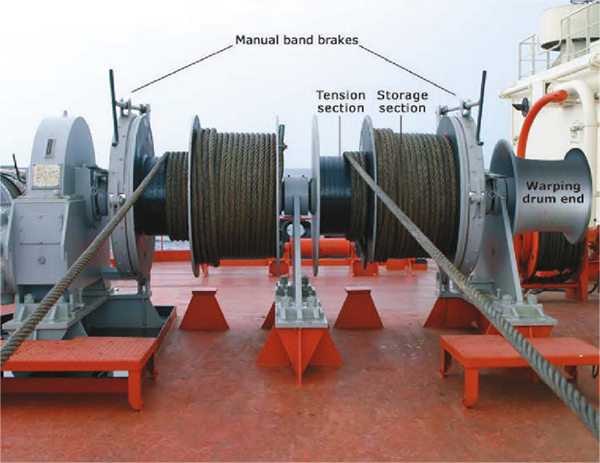

Marine Electric Double Drum Mooring Winch

An electric double drum mooring winch is a type of winch used for mooring operations on ships and other marine vessels. It consists of two drums, each with its own motor, that are used to handle and control the mooring lines. Winch drums can be either split or undivided. On an undivided drum outer layers of mooring line tend to embed into lower layers when under tension which can damage the mooring line. The split drum winch was designed as a solution to this problem and is preferred by most operators. The split drum winch is composed of a tension section (sometimes called the working section), and a line storage section.

Overview

Electric double drum mooring winch drives have some advantages over hydraulic drives, including reliable operation, reduced maintenance and the low risk of oil leakage or pollution. Electric motors are required to have a fail-safe brake to prevent the winch and motor paying out when the electrical power is off. Electric winch drives and their associated equipment should be designed to the appropriate hazardous classification for the area in which they operate. The main types of electric winches currently found on tankers are frequency controlled and pole changing.

Winch drum type includes the split drum and undivided drum:

1. Undivided drum

Advantages

• The mooring line does not need to transfer from section to section as is required for a split drum, which eliminates the potential for mooring line damage and personnel injury.

Disadvantages

• The outer layers of mooring line tend to embed into the lower layers when under tension. This is particularly an issue with synthetic mooring lines as mentioned above.

• Mechanical spooling devices on undivided drums are prone to damage.

2. Split drum

The split drum winch is a common drum divided by a notched flange into: A storage section and A tension/working section.

Advantages

• Maintains a constant brake holding capacity and heaving force because the mooring line is designed to run off the first layer of the tension section.

• The mooring line cannot embed into the lower layers when under tension, because there is only a single layer of turns on the tension part of the drum. This avoids potential damage to the mooring line.

Disadvantages

• The mooring lines need to transfer between the tension and storage drums which risks damage to the mooring lines and to personnel. Risks can be mitigated by planning the mooring operation to take into account spooling requirements, procedures, training and operator experience.

See following photos for examples.

The split drum winch is operated with only one layer of mooring line on the tension section and theoretically can maintain a constant, high brake holding power.