Maintenance Tips for Marine Anchor Windlass

Proper maintenance of marine windlasses is essential to ensure their reliable operation and longevity.

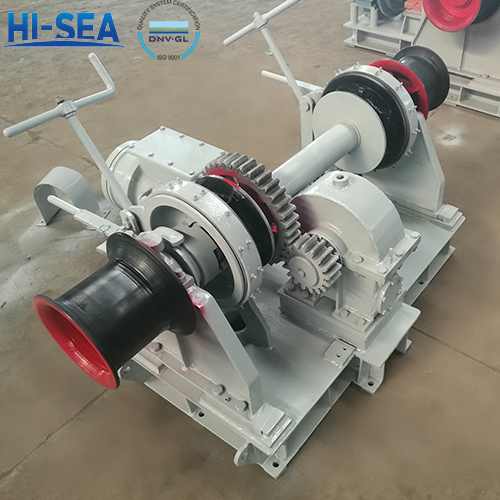

★ The mechanical part of the marine anchor windlass should work under good lubrication conditions. After each refuelling, the machine should be idle for a moment to evenly coat the running surface with grease

★ The refuelling parts include the grease nozzle, transmission rod, gear, brake lever, etc.

★ The machine body and fixing bolts should be regularly checked for completeness and tightness. The machine's brakes should be checked regularly, and grease should not adhere to the brake surface. When the brake belt rivets rub against the brake hub, the brake belt should be replaced on time.

......

Overview

The maintenance of ship windlass is crucial for the safe operation of ships. Here are some maintenance suggestions for marine anchor windlass:

Regular inspections:

Regularly inspect all windlass components, including the motor, gearbox, bearings, sprockets, chains, etc., to ensure their normal operation.

Check if the fasteners are loose, and if there are any damaged or worn parts, and repair or replace them promptly.

Cleaning and lubrication:

Regularly clean the external surface of the windlass to ensure that there is no accumulated dirt and salt.

For components that require lubrication, such as sprockets, bearings, etc., use appropriate lubricants for lubrication to reduce friction and wear.

Electrical system inspection:

Check the electrical system of the windlass, including the motor, switch, cable, etc., to ensure that the electrical connections are firm and reliable and that there are no damaged or corroded electrical components.

Regularly test the operation of the electrical system to ensure that the windlass can start and stop normally.

Chain and rope maintenance:

Check the chains or ropes used by the windlass to ensure that there is no wear, breakage, or corrosion.

Regularly clean chains or ropes to prevent accumulated dirt and salt from causing wear and corrosion.

Seal and gasket inspection:

Check the seals and gaskets of the windlass to ensure they show no signs of wear or ageing.

Timely replace damaged or aged seals and gaskets to prevent moisture and dirt from entering the interior of the anchor.

Regular lubrication:

For lubrication components such as gearboxes, bearings, etc., regular lubrication should be carried out to reduce friction and wear.

Use marine-grade lubricants and follow the manufacturer's recommendations for lubrication.

Professional maintenance:

Regular maintenance, inspection, and upkeep of the windlass shall be carried out by professional technical personnel.

Follow the manufacturer's maintenance manual and recommendations to ensure that the maintenance work of the windlass is carried out correctly.

By following these maintenance recommendations, the reliable operation of ship windlass can be ensured, and its service life can be extended, thereby ensuring the safety and stability of the ship.

For more marine anchor windlass information, kindly please click here.