How to selecting hoists

Overview

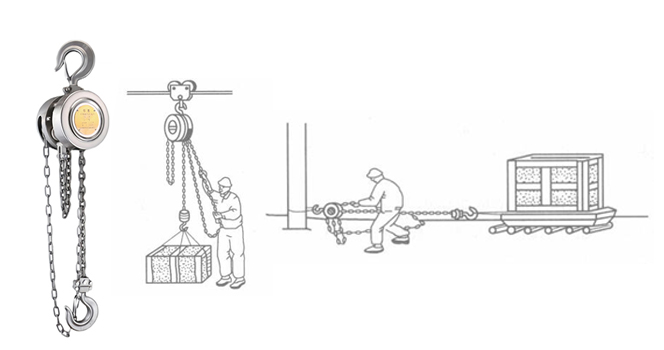

Manual Hoist

Manual hoists are operated by hand and do not require external power sources. They typically consist of a chain or a wire rope and pulley system, with the operator using a hand chain to lift and lower loads. The manual hoist is small in size, light in weight, and can be used in any direction such as horizontal, vertical, or tilted. Specific applications include short-distance shifting and installation of small equipment and various heavy objects, bundling and tightening of ropes during transportation of larger equipment and components, and lifting of lightweight loads. The manual hoist has two working classes: Class Z, indicating heavy-duty and frequent use; Class Q, indicating light-duty and infrequent use.

Electric Hoist

Electric hoists are powered by electricity and use an electric motor to lift and lower loads. They often feature a wire rope or chain wound around a drum, providing vertical lifting capability. Electric hoists offer precise control and are suitable for a wide range of offshore lifting applications. They can handle heavier loads compared to manual hoists. Electric hoists are widely employed offshore for lifting heavy equipment, materials, and tools during installation, maintenance, and construction activities on platforms and oil rigs.

Pneumatic Hoist

Pneumatic hoists, also known as air hoists, are powered by compressed air. These hoists use pneumatic systems to lift and lower loads and offer variable speed control. Pneumatic hoists are suitable for offshore environments where electrical power may pose safety concerns, and they are known for their reliability and ability to operate in potentially explosive atmospheres. Pneumatic hoists find applications offshore for lifting and positioning tasks, particularly in areas where the use of electric hoists may be restricted due to safety considerations or where a pneumatic power source is readily available.