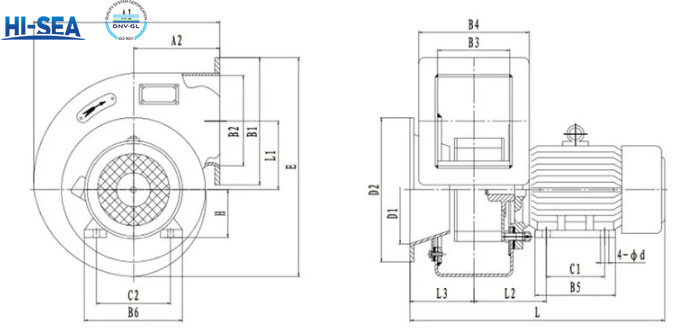

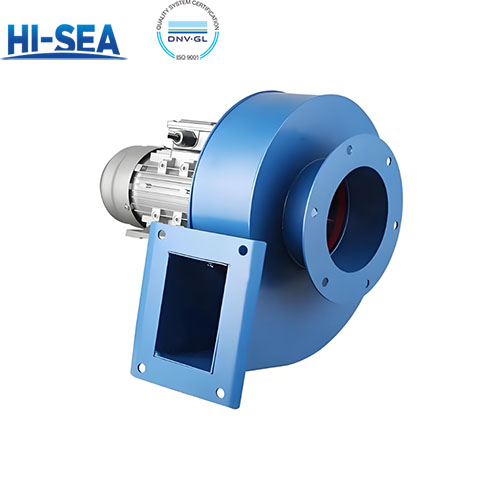

Boat Centrifugal Fan

The working principle of Boat Centrifugal Fan is to use a high-speed rotating impeller to generate centrifugal force, which throws gas from the center of the impeller towards the outer shell, allowing the gas to obtain kinetic energy and pressure energy. Through the expansion section of the outer shell, some of the kinetic energy is converted into pressure energy, and finally the gas is discharged from the outlet.

Overview

Features:

Shell: Made of cast iron or welded with steel plates, it can be horizontally divided or volute shaped according to the impeller form.

Rotor components: including impeller, main shaft, shaft sleeve, exhaust chamber, balance disk, seal, coupling and other components. The impeller increases gas pressure and flow rate by rotating.

Sealing system: Adopting labyrinth gas seals and other sealing structures to ensure that gas does not leak.

Imported blade adjustment device: By adjusting the angle of the blades, the gas flow rate can be controlled to meet different work requirements.

Bearing and lubrication system: Sliding bearings or rolling bearings are used, and the lubrication system ensures the long-term stable operation of the fan.

Applications:

Ventilation and air exchange: used for ventilation and air exchange in various compartments to maintain fresh air inside.

Air conditioning system: drives marine air conditioners to provide a comfortable cabin environment.

Boiler ventilation: plays a role in boiler blowing and induced draft to ensure combustion efficiency and safety.

Hovercraft propulsion: used for elevating and propelling hovercrafts to improve their maneuverability.

Advantages:

Environmental protection and energy conservation: By utilizing natural wind power to provide power, fuel consumption is reduced, and navigation costs are lowered.

Improve safety: As a backup power source, increase the safety of the ship.

Pictures: