What is Marine Globe Valve?

Globe valves are commonly used in various industries, such as sea water, oil and gas, water treatment, and manufacturing, due to their versatility and ability to regulate flow accurately. They are often preferred for applications that require fine control over the fluid flow.

Overview

Working Principle

Globe valve is a type of control valve commonly used in pipelines to regulate fluid flow. The working principle of a globe valve involves a movable disk or plug that is positioned against the flow of the fluid, controlling the rate of flow through the valve.

Here's a breakdown of the basic working principles:

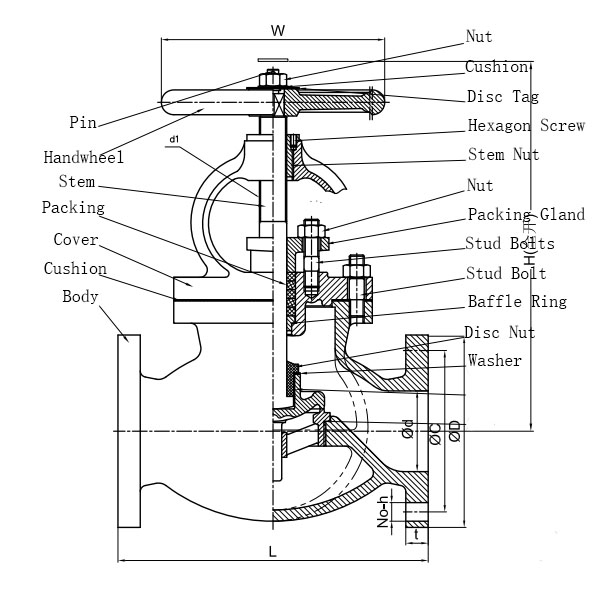

-Body and Bonnet: Globe valves have a spherical body with an internal chamber and a bonnet that holds the movable parts.

-Disk or Plug: Inside the valve, there's a disk or plug that can be moved up or down. This movement is typically controlled by a handwheel, actuator, or other types of control mechanisms.

-Seat: The disk or plug has a sealing surface, called the seat, which comes in contact with another sealing surface in the body when the valve is closed. This creates a tight seal, preventing fluid from flowing through.

-Flow Control: When the handwheel or actuator is turned, the disk or plug is lifted or lowered, allowing more or less fluid to pass through the valve. This control mechanism provides precise regulation of the flow rate.

-Flow Direction: The fluid enters the valve through the inlet, and its flow direction can be changed by the position of the disk or plug. The fluid then exits through the outlet.

Image of the Globe Valve