What is a marine mechanical brake for shafting?

It is suitable for small and medium vessels whose stern shafts need to be locked when they anchor. Marine shaft mechanical brake is a device used to control the rotation of the ship's propulsion shaft system. It applies braking force mechanically to achieve deceleration, parking, or maintaining a fixed position of the ship. Mechanical brakes play an important safety protection role in ship propulsion systems.

Overview

It is suitable for small and medium vessels whose stern shafts need to be locked when they anchor.

For more marine shaft system components, kindly please click here.

The main functions of brakes

Ship stopping: In emergency situations, quickly stop the ship to avoid collisions or other accidents.

Maintain position: When a fixed position is required, such as when berthing at a port, keep the vessel stationary.

Assisted deceleration: When entering or exiting ports or narrow waterways, assist the propeller in deceleration to ensure safe operation..

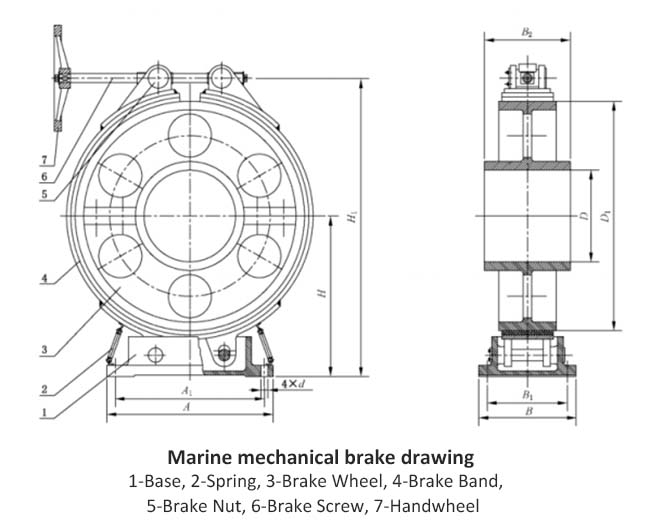

Marine mechanical brake drawing

Inspection and maintenance

In order to ensure the reliability and effectiveness of marine shaft mechanical brakes, regular inspections and maintenance must be carried out:

1. Appearance inspection:

Wear inspection: Regularly check the wear of brake pads, brake discs, or brake drums to ensure they are within the safe range of use.

Fastener inspection: Check if all fasteners are loose or missing to ensure that all components are securely fastened.

2. Functional testing:

Braking force test: Using specialized testing equipment, measure the braking force of the brake to ensure that it meets the design requirements.

Response speed test: Check the response time of the brake from the application of the braking signal to the actual generation of braking force to ensure rapid response.

3. Lubrication and cleaning:

Lubrication: Regularly lubricate moving parts to ensure smooth operation.

Cleaning: Remove dust, oil, and debris from the brake to prevent them from affecting the braking effect.

Through regular inspection and maintenance, it can be ensured that the mechanical brakes of marine shaft systems can work reliably when needed, ensuring the safe operation of the ship.

Main parameters

Specification | D | D1 | H | H1 | A | A1 | B | B1 | B2 | 4*d mm | Ultimate torque kN*m | Weight (kg) |

JZ60 | 60 | 380 | 285 | 505 | 320 | 260 | 160 | 110 | 100 | 21 | 12.48 | 84 |

JZ70 | 70 | 83 | ||||||||||

JZ80 | 80 | 82 | ||||||||||

JZ90 | 90 | 81 | ||||||||||

JZ100 | 100 | 80 | ||||||||||

JZ110 | 110 | 500 | 355 | 645 | 380 | 320 | 200 | 150 | 180 | 21 | 16.10 | 124 |

JZ120 | 120 | 123 | ||||||||||

JZ130 | 130 | 122 | ||||||||||

JZ140 | 140 | 121 | ||||||||||

JZ150 | 150 | 120 | ||||||||||

JZ160 | 160 | 620 | 450 | 820 | 440 | 380 | 260 | 200 | 240 | 21 | 19.97 | 190 |

JZ170 | 170 | 188 | ||||||||||

JZ180 | 180 | 186 | ||||||||||

JZ190 | 190 | 184 | ||||||||||

JZ200 | 200 | 182 | ||||||||||

JZ210 | 210 | 750 | 520 | 960 | 560 | 500 | 300 | 240 | 280 | 25 | 24.16 | 300 |

JZ220 | 220 | 295 | ||||||||||

JZ230 | 230 | 290 | ||||||||||

JZ240 | 240 | 285 | ||||||||||

JZ250 | 250 | 280 | ||||||||||

Note: the size of this table are for reference. The products can be manufactured according to client’s requirement. | ||||||||||||