The difference between marine hydraulic anchor windlass and electric anchor windlass

Both hydraulic and electric anchor windlasses serve the same fundamental purpose: they are mechanical devices used to raise and lower an anchor on a boat or ship. However, they differ in terms of their power source, mechanism of operation, and certain performance characteristics.

Overview

Here's a breakdown of the main differences between marine hydraulic and marine electric anchor windlasses:

1. Power Source:

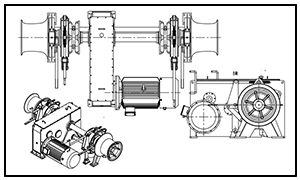

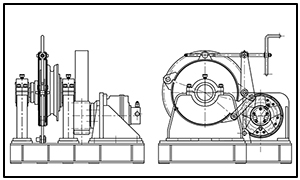

Marine Hydraulic Anchor Windlass: Hydraulic windlasses are powered by hydraulic systems that utilize pressurised hydraulic fluid to generate mechanical force. Hydraulic systems typically rely on a hydraulic pump, which may be powered by an engine or an electric motor, to pressurize the hydraulic fluid.

Marine Electric Anchor Windlass: Electric windlasses, on the other hand, are powered directly by electricity. They are typically connected to the vessel's electrical system and rely on electric motors to drive the windlass mechanism.

2. Mechanism of Operation:

Marine Hydraulic Anchor Windlass: Hydraulic windlasses operate by using hydraulic pressure to drive a hydraulic motor, which in turn rotates the windlass drum or gypsy to raise or lower the anchor chain or rope.

Marine Electric Anchor Windlass: Electric windlasses utilize an electric motor to directly drive the windlass drum or gypsy. The motor is powered by electricity and switches or a control panel on the vessel.

3. Performance Characteristics:

Power and Speed: Hydraulic windlasses tend to be more powerful than electric windlasses, particularly in larger vessels, as hydraulic systems can generate higher torque. They may also offer more precise control over the speed and force applied to the anchor.

4. Efficiency: Electric windlasses are generally more efficient in terms of energy consumption, as they do not suffer from hydraulic losses associated with fluid flow. They may also be easier to maintain and repair, as they have fewer moving parts compared to hydraulic systems.

5. Cost: Hydraulic windlasses are often more expensive to purchase and install compared to electric windlasses, primarily due to the additional components required for the hydraulic system, such as pumps, hoses, and valves.

6. Installation and Integration:

Marine Hydraulic Anchor Windlass: Hydraulic systems require additional components and space for hydraulic pumps, reservoirs, and hoses. Installing a hydraulic windlass may require more complex plumbing and integration with the vessel's hydraulic system.

Marine Electric Anchor Windlass: Electric windlasses are generally easier to install and integrate with the vessel's electrical system. They require less space and fewer additional components compared to hydraulic systems.

Ultimately, the choice between a hydraulic and electric anchor windlass depends on factors such as the vessel's size, power requirements, operational preferences, and budget constraints. Both types of windlasses have their advantages and limitations, and the decision should be based on the specific needs and requirements of the vessel and its operators.

For more marine hydraulic anchor windlass specifications, please click here.

For more marine electric anchor windlass specifications, please click here.

For more marine anchor windlass information, kindly please click here.

| The difference between marine hydraulic anchor windlass and electric anchor windlass | |

|  |

And you need know the anchor chains, please click here.

If you need know the marine anchors, please click here.