Structure and classification of marine oil lubrication stern shaft sealing apparatus

The stern shaft oil lubrication sealing device for ships is suitable for various types of ships with oil as the working medium.

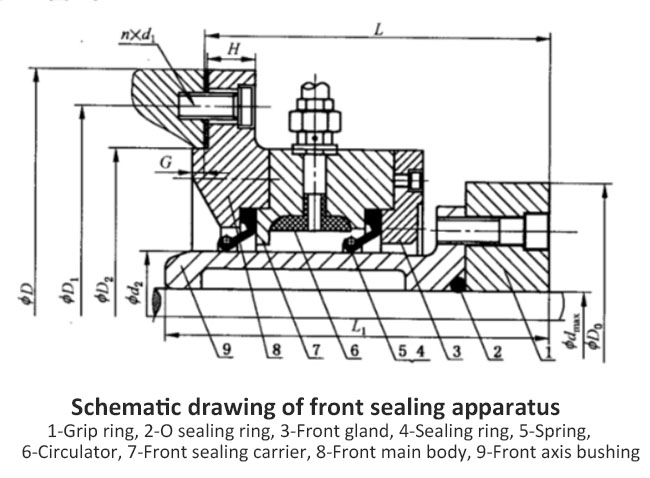

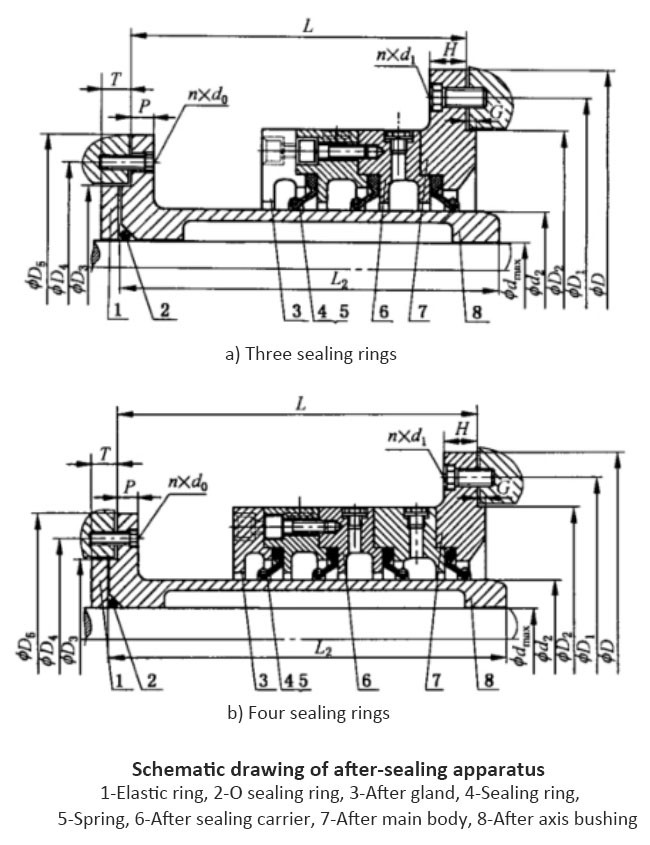

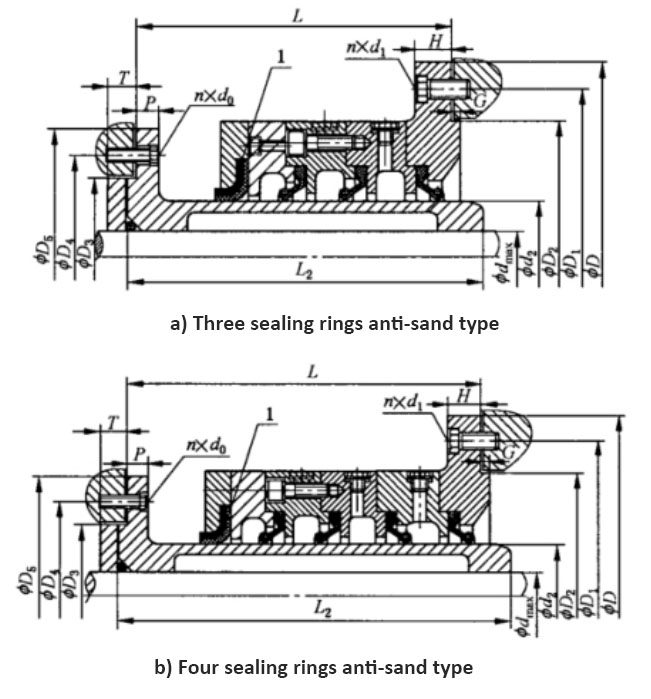

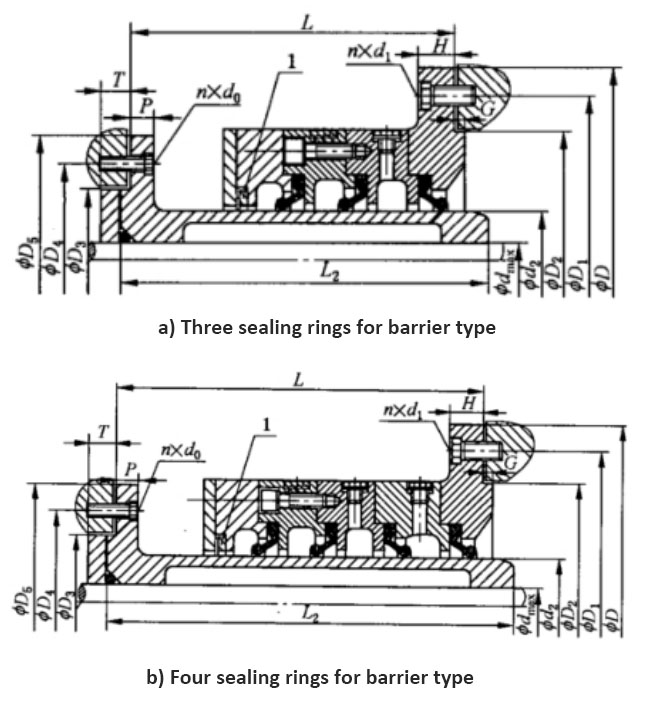

The marine oil lubricated stern shaft sealing device mainly consists of main body, seal carrier, gland, axis bushing, grip ring, and elastic ring.

Oil lubrication stern shaft sealing apparatus are divided into two types based on their installation positions: front sealing devices and after sealing devices.

Overview

Terms and definitions:

Main body: a component that is connected and matched with the front and rear ends of the stern tube.

Seal carrier: a component used to install and position a sealing ring.

Gland: The outer component used to clamp and position the sealing ring.

Axis bushing: a sleeve that prevents corrosion and wear on the stern shaft.

Grip ring: a split type component that is fixed on the stern shaft and rotates together with the stern shaft due to its clamping force generating frictional force.

Elastic ring: a gasket placed between the propeller and the bushing.

Classification and structure of marine oil lubrication stern shaft sealing apparatus

Oil sealing devices are divided into two types based on their installation positions: front and rear sealing devices.

Front sealing device: The front sealing device is equipped with two rings, as shown in the figure:

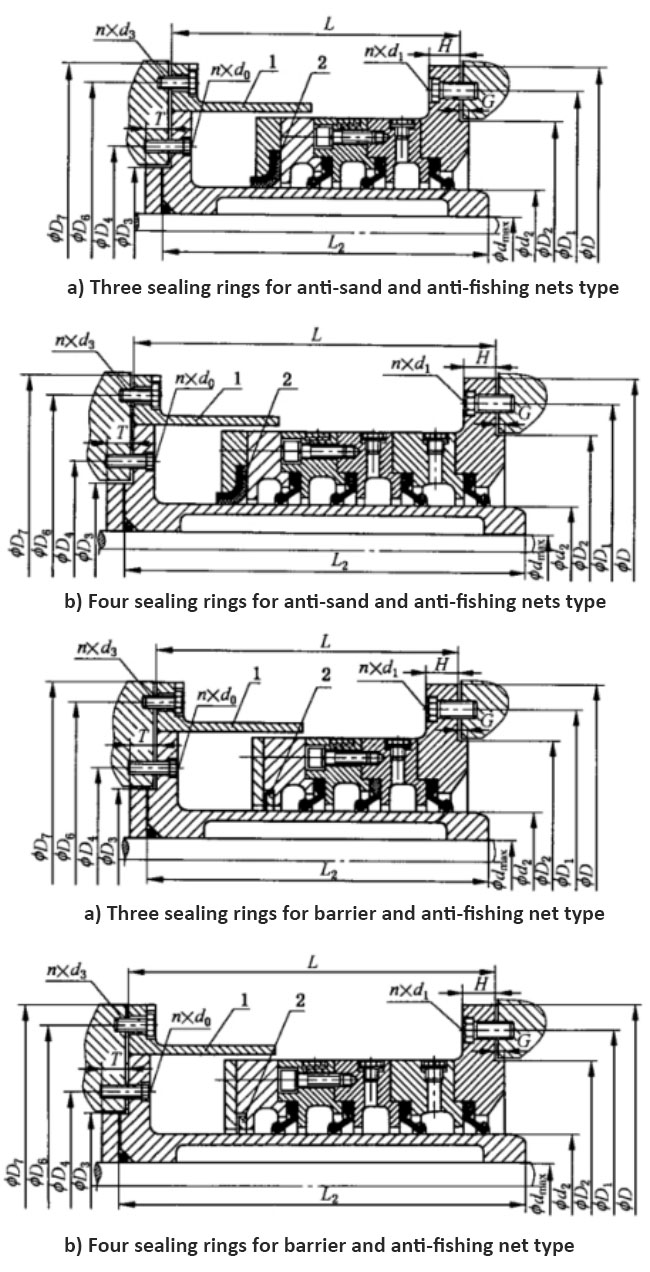

Rear/after sealing device: The after sealing device is equipped with three or four rings, which are divided into anti sand type, carrier type, and anti sand and anti fishing net type according to their functions. As shown in the following figure.

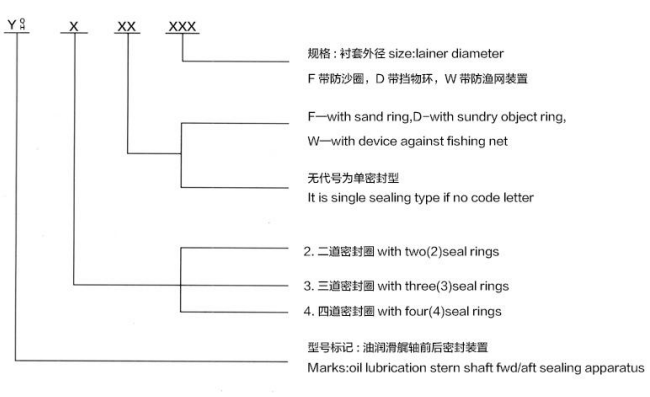

Model representation method:

The representation method for oil sealing devices consists of product name and technical features, and the product model marking method is as follows:

For more stern shaft sealing apparatus, kindly please click here.

For more marine shaft system components, kindly please click here.