Rectangle Type Gooseneck Ventilation

Rectangle Type Gooseneck Ventilation effectively reduces the temperature and humidity in the cabin of a boat, preventing problems such as corrosion and mold inside the hull. In order to ensure the performance and safety of the ventilator, the vessel needs to strictly comply with the relevant standards and specifications during the design and manufacturing process. The material selection, manufacturing process and installation location of the ventilator need to be strictly considered and tested. At the same time, regular maintenance and inspection are also essential to ensure that the ventilator is always in good working condition in the harsh marine environment.

Overview

Common defects:

1. The cover, barrel, and supporting elbow plate at the bottom of the barrel are badly corroded or even pierced.

2. The sealing packing of the weathertight cover is deteriorated or lost, the cover is deformed and cannot guarantee to keep sealing with the top edge of the ventilated cylinder body.

3. Insect screens are damaged, spiral roll buckles are missing, and hinge connections are ineffective or missing, making it impossible to close the ventilator quickly.

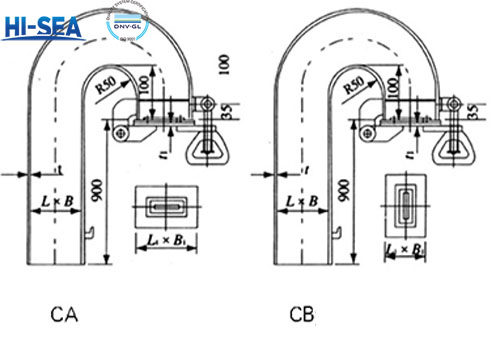

Drawing:

DN | L*B | t | L1*B1 | t1 | kg |

100 | 120*80 | 4 | 138*98 | 6 | 21.1 |

6 | 146*106 | 8 | 29.2 | ||

8 | 40.9 | ||||

150 | 150*120 | 4 | 168*136 | 6 | 30.1 |

6 | 176*146 | 8 | 44.2 | ||

8 | 55.2 | ||||

200 | 220*150 | 5 | 240*170 | 6 | 51.1 |

6 | 246*176 | 8 | 55.3 | ||

8 | 78.5 | ||||

250 | 300*240 | 5 | 300*210 | 6 | 67.1 |

6 | 306*216 | 8 | 71.3 | ||

8 | 104.1 | ||||

300 | 300*240 | 6 | 328*268 | 9 | 97.5 |

9 | 140.3 | ||||

350 | 360*290 | 6 | 390*320 | 10 | 125.5 |

9 | 192.1 | ||||

400 | 460*290 | 6 | 490*320 | 10 | 151.3 |

10 | 244.6 |