Performance requirement of marine water lubrication stern shaft sealing apparatus

When producing marine water lubrication stern shaft sealing apparatus, its requirements and performance should be comply with GB/T 25018-2010 standards.

Marine water lubrication stern shaft sealing apparatus is suitable for kinds of vessels whose working medium is water.

When the axial vibration ≤ 1mm, the SM type can be used;

When the axial vibration ≤ ±3mm and the speed is high,the SMB type can be used.

Overview

Design and Structure

The design and structure of the rubber ring type water sealing device should meet the following requirements:

a) The main structure of the water sealing device should consist of an inflatable radial seal and a dual channel end face sealing device, with inflatable seals and end faces

Sealed in the same shell, and the end face seal is equipped with a spare sealing ring;

b) The device should be equipped with corresponding cooling water joints, compressed air joints, and breathable drain plugs; c) The joint surface between the water sealing device and the ship shaft should be equipped with sealing gaskets;

d) The rubber sealing ring should not have pores or cracks.

The design and structure of the packing box type water sealing device should meet the following requirements: a) The main structure is composed of two packing seals, separated by a distributor in the middle; b) Corresponding cooling water joints and breathable drain plugs should be equipped.

3. The spring leaf type water sealing device should meet the following requirements:

a) The elastic body should be able to automatically compensate for the wear of the sealing friction pair and the elastic deformation of the shaft vibration and impact within the designed displacement compensation range;

b) It should be able to avoid mechanical shaft jamming under the maximum possible bending deformation of the shaft system.

4. The column spring type water sealing device should be able to meet the following requirements;

a) The sealing friction pair is composed of hard alloy dynamic and static rings, and the dynamic ring is driven by the elastic force of the column spring to maintain the sealing friction pair and achieve dynamic end face water sealing

b) Using zinc rings to extend the corrosion resistance life of water sealing devices.

Requirement

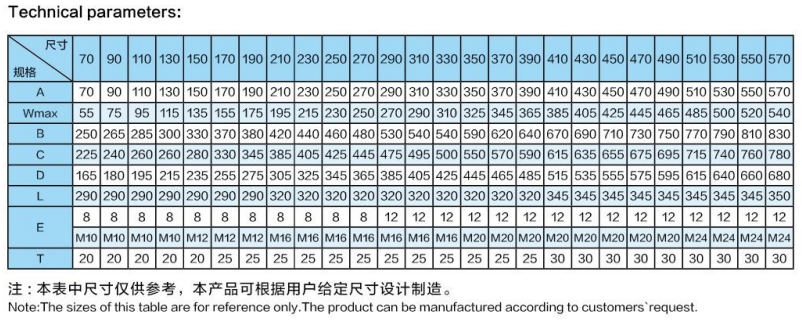

1. Main parameters

2. Appearance:

a) The water sealing device should not be knocked, bumped, or scratched.

b) The surface of the elastic body of the spring type water sealing device should be flat and smooth, without burrs, bumps, and any mechanical scratches.

c) All parts should be cleaned thoroughly and free of burrs, burrs, scale, rust, chips, oil stains, colorants, and dust.

Performance

1. Sealing performance

a) Static: In the stationary state of the shaft system, the water leakage of the water sealing device is 0.

b) Dynamic:

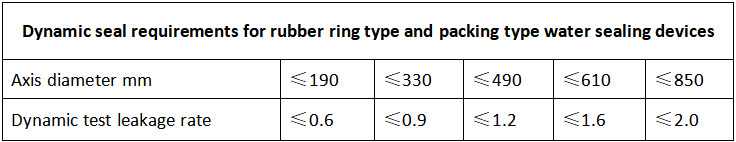

The dynamic sealing performance of rubber ring type water sealing device and packing box type water sealing device should meet the following requirements:

Under normal operation of the shaft system, the water leakage of the spring leaf type water sealing device should not exceed 1.5L per 100 mm shaft diameter per hour.

The water leakage of the column spring type water sealing device should not exceed 0.1 L/h under normal operation of the shaft system.

2. Wear resistance

The wear of the friction pair between the rubber ring type water seal device and the packing box type water seal device shall not exceed 0.02mm after 100 hours of operation.

The spring type water seal device operates for 100 hours at a relative rotational speed of no more than 7.5 m/s, and the sum of the wear of the dynamic and static rings is not more than 1.5 μ m/h.

The column spring type water sealing device operates for 100 hours at a relative rotational speed of no more than 7.5 m/s, and the sum of the wear of the dynamic and static rings is not more than 0.5 μ m/h.

3. Pressure resistance strength of the shell body

The shell of the water sealing device does not leak for 0.5 hours under a pressure of 0.3 MPa.

4. Temperature rise

The temperature rise of the outer shell of the water sealing device should not exceed 30 ℃ under normal working conditions.

5. Reliability

The average time between failures (MTBF) of the water sealing device is:

a) Rubber ring type and packing box type should not be less than 6400 hours;

b) The spring type should not be less than 3000 hours;

c) The column spring type should not be less than 8000 hours.

For more stern shaft sealing apparatus, kindly please click here.

For more marine shaft system components, kindly please click here.