Marine Crane

A marine crane is a specialized type of crane designed for use on ships, offshore platforms, or other marine vessels. These cranes are essential for handling cargo, equipment, and materials in ports, onboard ships, and offshore operations. Marine cranes are engineered to withstand the harsh conditions of the marine environment, including exposure to saltwater, wind, and waves. They come in various configurations and sizes depending on the specific application and vessel requirements.

Overview

A marine crane is a specialized type of crane designed for use on ships, offshore platforms, or other marine vessels. These cranes are essential for handling cargo, equipment, and materials in ports, onboard ships, and offshore operations. Marine cranes are engineered to withstand the harsh conditions of the marine environment, including exposure to saltwater, wind, and waves. They come in various configurations and sizes depending on the specific application and vessel requirements.

Features

Driven type: electric or hydraulic

Boom type: fixed boom, knuckle boom, telescopic boom, telescopic knuckle boom, etc.

Slewing angle: 360 degree

Working load from 5kN to 300kN

Local control or remote control

Protection level: IP56

Heel≤5°, trim≤2°

Can be designed and manufacture to suit customers applications and special operating requirements.

Can be approved by CCS, BV, RMRS ......

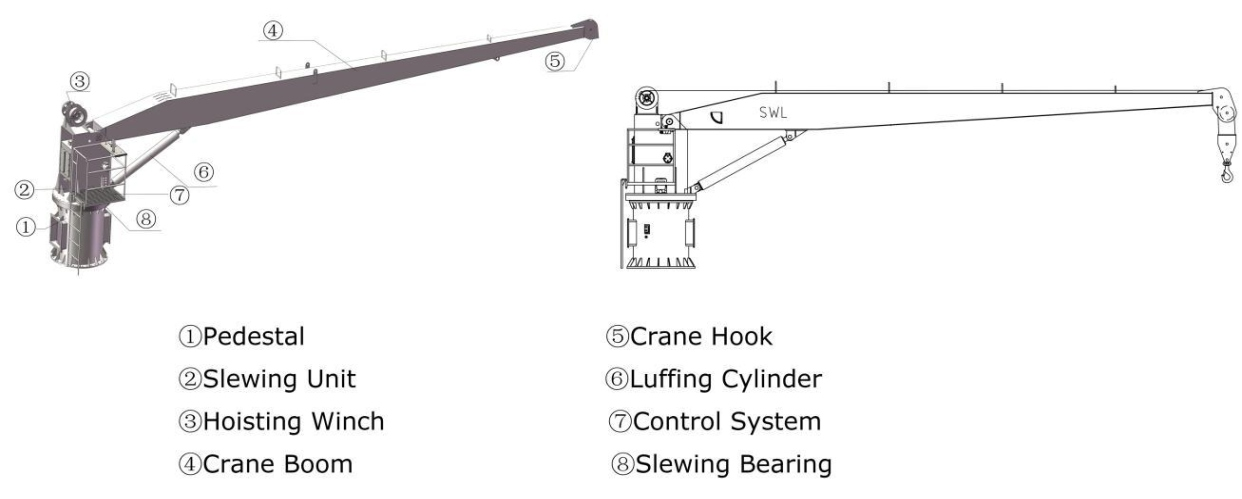

Marine Crane Structure

Marine Crane Classification

| Marine Crane Classfication | |||

More marine crane information, kindly please click here.

Main technical parameters

Safety Load(kN) | Max Working Radius(m) | Min Working Radius(m) | Hoisting Speed(m/min) | Slewing Speed(r/min) | Luffing Time(s) | Slewing Angle(°) | Permission Trim/Heel (°) | Hoisting Height(m) | Power(kW) |

10 | 6~12 | 1.3~2.6 | 15 | 1 | 60 | 360 | 2°/5° | 30 | 7.5 |

15 | 8~14 | 1.7~3 | 15 | 1 | 60 | 360 | 2°/5° | 30 | 11 |

20 | 5~15 | 1.1~3.2 | 15 | 1 | 60 | 360 | 2°/5° | 30 | 15 |

30 | 8~18 | 1.7~3.8 | 15 | 0.9 | 70 | 360 | 2°/5° | 30 | 22 |

50 | 12~20 | 2.5~4.2 | 15 | 0.75 | 80 | 360 | 2°/5° | 30 | 37 |

80 | 12~20 | 2.5~4.2 | 15 | 0.75 | 100 | 360 | 2°/5° | 30 | 55 |

100 | 12~20 | 2.5~4.2 | 15 | 0.75 | 110 | 360 | 2°/5° | 30 | 75 |

150 | 12~20 | 2.5~4.2 | 15 | 0.6 | 110 | 360 | 2°/5° | 30 | 90 |

200 | 16~25 | 3.2~5.3 | 15 | 0.6 | 120 | 360 | 2°/5° | 35 | 75*2 |

250 | 20~30 | 3.2~6.3 | 15 | 0.5 | 130 | 360 | 2°/5° | 40 | 90*2 |

300 | 30 | 3.2~6.3 | 15 | 0.4 | 140 | 360 | 2°/5° | 40 | 90*2 |

350 | 20~35 | 4.2~7.4 | 15 | 0.5 | 150 | 360 | 2°/5° | 45 | 110*2 |

400 | 20~35 | 4.2~7.4 | 15 | 0.5 | 150 | 360 | 2°/5° | 45 | 140*2 |

450 | 25~40 | 5.3~8.5 | 15 | 0.45 | 160 | 360 | 2°/5° | 50 | 140*2 |

500 | 25~40 | 5.3~8.5 | 15 | 0.45 | 170 | 360 | 2°/5° | 50 | 165*2 |