Marine Air Receiver

The marine air receiver is a bottle that is designed to store compressed air and supply start up or air whistle for main engine and auxiliary engine.

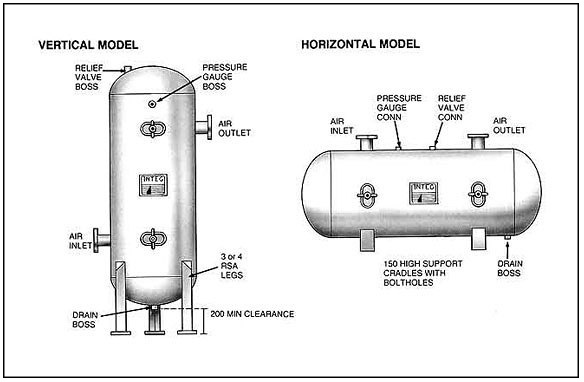

In the marine diesel engine power plant, the main air receiver and auxiliary air receiver are generally provided. It can be divided into the horizontal air receiver and the vertical receiver according to its structure. There are low pressure air receiver, medium pressure air receiver, and high pressure air receiver according to its rated pressure.

Overview

As an important equipment on ships, the design requirements for components and materials of marine air bottles are very strict to ensure their safe and reliable operation in harsh marine environments. Marine air receiver mainly consists of the body, bottle head valve, safety valve, inlet valve, outlet valve, drain valve, pressure gauge valve, and installation base.

The material selection of marine air bottles should consider factors such as strength, corrosion resistance, weldability, and economy. Common materials include carbon steel, stainless steel, and alloy steel. Specifically, the air receiver body is often made of steel with strength such as Q345R, while accessories such as valves may be made of cast steel or stainless steel. The performance parameters of marine air bottles include design pressure, working pressure, capacity, weight, etc. These parameters need to be determined based on the specific needs and regulatory requirements of the vessel.

For more marine vertical air receiver information, please click here.

For more marine horizontal air bottle information, please click here.

Feature:

With vertical or horizontal type

Excellent sealing property

High quality, long life span

High pressure resistance

Corrosion resistance

Explosion-proof

Good stability

Approved by CCS, BV...

Can be customized according to your needs.

Drawing for Marine Air Receiver

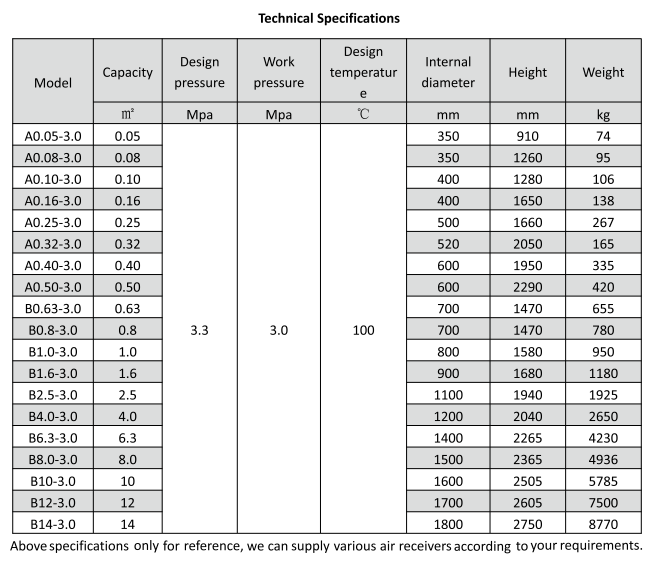

Main Technical Parameter