Marine Vertical Air Receiver

The marine vertical air bottles are indispensable for the safe and efficient operation of marine vessels. Their ability to store and provide high-pressure compressed air makes them a critical component in engine starting, fire suppression, and various pneumatic systems on board, ensuring that ships can operate smoothly and safely in the demanding marine environment.

Overview

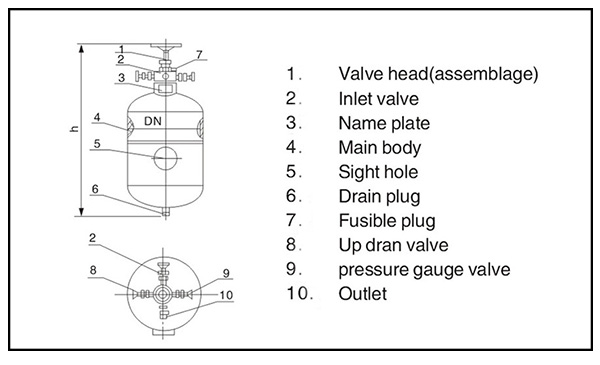

The marine vertical air receiver, also know as air bottle, is a crucial component in maritime engineering, specifically designed for storing compressed air on ships and marine vessels. It mainly consists of the main body, intake valve, exhaust valve, pressure gauge, drain valve, safety valve, and fusible plug. A fusible plug is installed in the bottle with a separate connection to the outside of the cabin so that in the event of a fire, the plug will melt and release all air to the outside atmosphere. Some regular inspections is necessary including checking the pressure, tightness and corrosion of the air bottle to ensure its safety and reliability. It also needs to be drained regularly to prevent internal water from corroding the bottle. The materials used for this marine vertical air receiver comply with the requirements of CCS Rules for Materials and Welding. The air receiver body longitudinal welded joint, the ring joint between the air receiver and the head, and the head splicing joint all adopt a fully welded butt joint type.

Feature:

Corrosion resistant

Less wear

Space-saving

Low maintenance and inspection costs

High quality, long service life

Good sealing property

Class certificate: CCS, BV, RINA...

Can be customized according to the specific needs.

Drawing for Marine Vertical Air Receiver

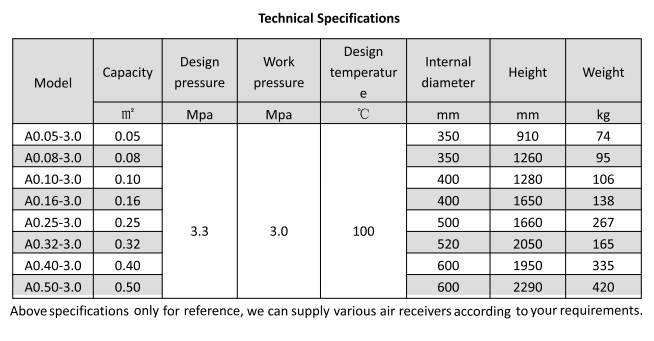

Main Technical Parameter