Marine Horizontal Air Bottle

The marine horizontal air bottle is a large container with a horizontal structure acting as a reservoir to store compressed air supplied by the main air compressor of the ship at rated pressure. The air receiver stores compressed air generated by the ship's air compressors. These air bottles are horizontally oriented, which optimizes space utilization in the often confined and irregularly shaped engine rooms of ships.

Overview

The marine horizontal air bottles are usually constructed from high-strength steel or composite materials, which are built to withstand the harsh maritime environment, including exposure to saltwater, humidity, and varying temperatures. The material selection of marine air bottles should consider factors such as strength, corrosion resistance, weldability, and economy. Common materials include carbon steel, stainless steel, and alloy steel. Specifically, the air receiver body is often made of steel with strength such as Q345R, while accessories such as valves may be made of cast steel or stainless steel. Marine air receivers are to operate normally with the ship having a 15°heel, or 22.5°roll, or 5°trim or 7.5° pitch (where the length of the ship exceeds 100 m, the fore-and-aft static angle of inclination may be taken as 500/L, where L is the length of the ship, in m).

They are integral to the operation of various pneumatic systems on board, such as starting main and auxiliary engines, controlling valves, and operating other essential machinery that relies on compressed air.

Feature:

With horizontal structure

High quality, long service life

Reliable and stable performance

Durability, high strength

Good sealing effect

Class certificate: CCS, RS, BV or other

Can be customized according to specific needs

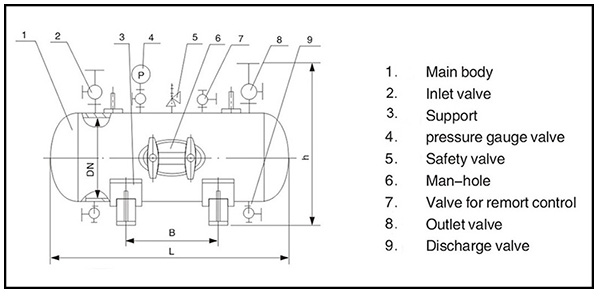

Drawing for Marine Horizontal Air Bottle

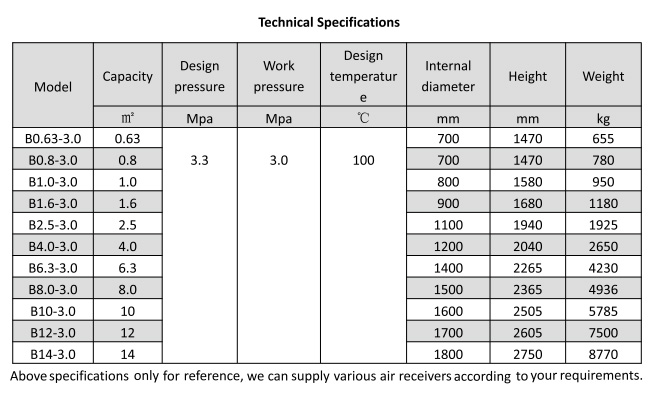

Main Technical Parameter