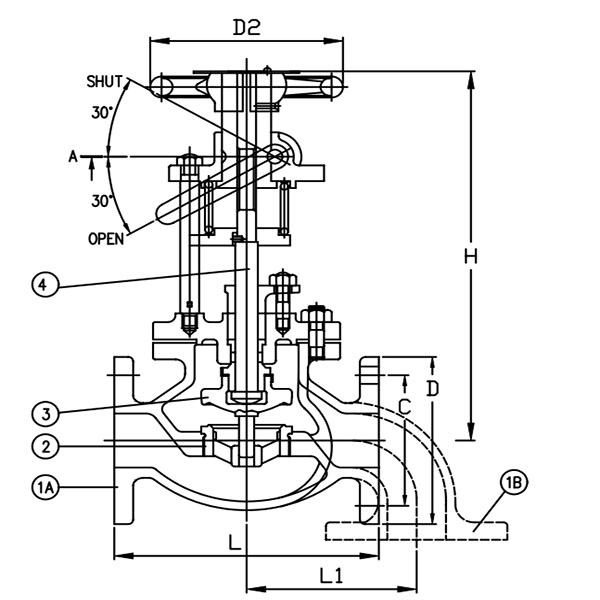

JIS F7399 Quick Closing Valve

Quick closing valves can be operated manually, pneumatically, hydraulically, or electrically, depending on the application and requirements. They are designed to close in a matter of seconds to prevent the release of hazardous materials or to isolate a section of a pipeline in the event of a leak or rupture.

Overview

Main Parts Material

For Sizes 25A & 40A

1A-Body: Bronze(BC6)

3-Disc: Bronze(BC6)

4-Stem: Brass(C3771BD)

For Sizes 50A & Higher

1B-Body: Cast Steel(SC49)

2-Seat: Stainless Steel(SCS2)

3-Disc: Stainless Steel(SCS2)

4-Stem: Stainless Steel(SUS403)

Drawing

Main Specifications

Size | 5K Flanged | 10K Flanged | H | D1 | ||||||||||||||

L | L1 | L2 | D | C | No. | h | t | L | L1 | L2 | D | C | No. | h | t | |||

25 | 130 | 75 | 60 | 95 | 75 | 4 | 12 | 10 | 130 | 80 | 65 | 125 | 90 | 4 | 19 | 14 | 265 | 120 |

40 | 160 | 100 | 75 | 120 | 95 | 4 | 15 | 12 | 170 | 85 | 80 | 140 | 105 | 4 | 19 | 16 | 310 | 140 |

50 | 210 | 125 | 90 | 130 | 105 | 4 | 15 | 14 | 220 | 125 | 90 | 155 | 120 | 4 | 19 | 16 | 335 | 160 |

65 | 250 | 155 | 100 | 155 | 130 | 4 | 15 | 14 | 270 | 155 | 100 | 175 | 140 | 4 | 19 | 18 | 395 | 180 |

80 | 280 | 165 | 120 | 180 | 145 | 4 | 19 | 18 | 300 | 165 | 120 | 185 | 150 | 8 | 19 | 18 | 420 | 180 |

100 | 340 | 200 | 130 | 200 | 165 | 8 | 19 | 18 | 350 | 200 | 130 | 210 | 175 | 8 | 19 | 18 | 510 | 224 |

125 | 410 | 250 | 160 | 235 | 200 | 8 | 19 | 20 | 420 | 250 | 160 | 250 | 210 | 8 | 19 | 20 | 440 | 250 |

150 | 480 | 300 | 180 | 265 | 230 | 8 | 19 | 22 | 490 | 300 | 180 | 280 | 240 | 8 | 19 | 22 | 520 | 320 |