Introduction to the Structure and Principle of Marine Boilers

Marine boilers refer to the equipment installed on ships for generating steam. Marine boilers have the following important functions:

Providing power: Steam can drive power devices such as steam turbines to propel the ship forward. Heating purposes: It can provide the required heat for various systems and equipment on the ship, such as heating fuel oil, lubricating oil, etc. Living needs: The generated steam can be used for living facilities on the ship, such as heating water, cooking, etc.

In short, marine boilers are one of the indispensable key equipment in the operation of ships. This article will focus on introducing the types, structures and principles of marine boilers for you to help you understand marine boilers.

Overview

What is marine boiler

marine boiler is a pressure vessel made of metal materials. Its main working principle is that through the combustion of fuel (such as coal, oil, gas, etc.) in the furnace, the chemical energy of the fuel is converted into thermal energy, and then the water is heated to make it evaporate into steam. In other words, it is just a heat exchanger that uses the radiant heat released from the combustion of fuel and the convection of hot flue gas to generate steam and hot water for heating or providing power.

The main types of marine boiler

Water-tube boiler

Fire-tube boiler

The main structure of marine boiler

Water-tube boiler

The structure of a marine water-tube boiler mainly includes the furnace, drum, safety valve, superheater, economizer, burner, air preheater and water tubes (riser tubes, downcomer tubes), etc. The functions of each part are as follows:

Furnace: It is the space for fuel combustion, providing a suitable environment for fuel combustion to make the fuel fully release heat.

Drum: It plays the roles of storing the steam-water mixture, performing steam-water separation, and balancing the water-vapor pressure, and it is an important part of the boiler steam-water cycle.

Safety valve: The main function is to automatically open when the pressure in the boiler exceeds the specified value, and discharge steam to prevent boiler overpressure and ensure the safe operation of the boiler.

Superheater: It is used to further heat the saturated steam to become superheated steam, improving the quality and enthalpy of the steam.

Economizer: It raises the boiler feed water temperature and reduces the flue gas temperature, playing the role of energy saving and emission reduction.

Burner: It is responsible for mixing the fuel and air in a certain proportion and carrying out efficient combustion to ensure the full combustion of the fuel.

Air preheater: It preheats the air entering the furnace to improve combustion efficiency and reduce energy waste.

Riser tube: It conveys the steam-water mixture generated by heating upward to the drum.

Downcomer tube: It conveys the water in the drum downward to each heated surface of the boiler to form a circulating flow of water.

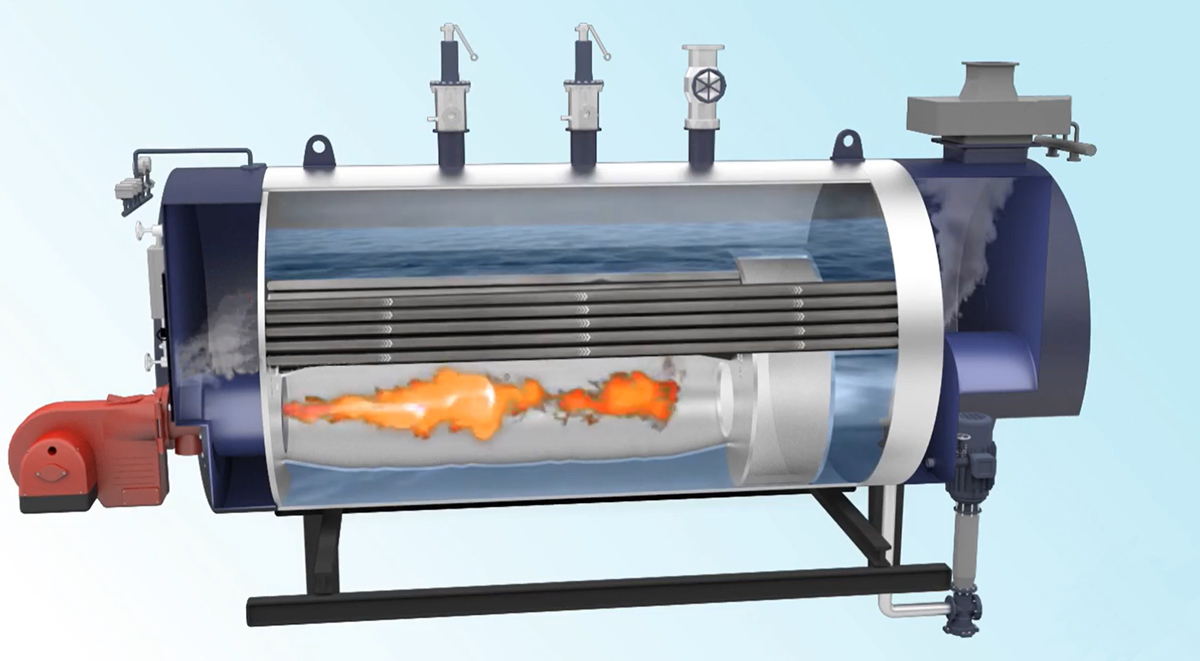

Fire-tube boiler

The structure of Marine fire tube boiler mainly includes:

Furnace: The space in which the fuel is burned and the water in the shell is transferred by thermal radiation.

Fire tube or smoke tube: The flue gas from burning fuel flows through it to transfer heat to an external mixture of water, steam, or soda.

Shell: The part that holds water and steam.

Burner: Used to burn fuel and convert chemical energy into heat energy.

Economizer: improve the boiler water temperature, reduce the smoke exhaust temperature, play a role in energy saving and emission reduction.

Safety valve: The main function is to automatically open when the pressure in the boiler exceeds the specified value, and the steam is discharged to prevent the boiler from overpressure and ensure the safe operation of the boiler.

The basic principles of marine boiler

Water-tube boiler

The working principle of a marine water-tube boiler is to utilize the thermosiphon principle. Through the riser and downcomer between the two steam drums, the water can naturally circulate and flow therein, so as to transfer the heat generated by fuel combustion to the water in the water pipe and heat it into steam. Specifically, the high-temperature flue gas generated by the fuel combustion in the furnace transfers the heat to the drum and water-cooled wall through the ways of radiation and convection, causing the water in the drum to be heated and evaporated into saturated steam. The saturated steam is further heated through the superheater to become superheated steam and then output for the use of the ship.

Fire-tube boiler

Fuel (such as fuel oil, gas, etc.) is combusted through the burner in the furnace to generate high-temperature flue gas. These flue gases flow in the fire tube or smoke tube.Water is injected into the boiler shell, and the boiler shell is in direct contact with the fire tube or smoke tube. The water is heated and gradually heats up and evaporates to form steam. The steam rises and enters the steam drum, and steam-water separation is carried out in the steam drum. The separated saturated steam may further enter the superheater.In the superheater, the saturated steam is further heated by the high-temperature flue gas to become superheated steam to improve the quality and enthalpy of the steam.At the same time, the economizer uses the waste heat of the flue gas to preheat the water entering the boiler to improve the inlet water temperature and achieve energy conservation and emission reduction.

Conclusion

The above is the entire content of this article. In the article, we have detailedly introduced to you the basic structure and principles of the marine boiler. We hope that through this article, it can help you choose the marine boiler.

Finally, if you have the need for procurement, you are welcome to visit our marine boiler homepage or contact us at any time! Thank you again for your browsing!