Filtration + Membrane Separation + Nitrogen Filling Deoxygenation Ballast Water Management System

Our Nitrogen feeding and de-oxygenation ballast water management system (BWMS) series products adopt modular design, with flexible layout and small space required for maintenance, and the designed rated treatment capacity range is 200 m³/ h to 4000 m³/h. There will be no more organisms breeding in the ballast tank, which is suitable for both long and short voyages. The nitrogen feeding and de-oxygenation technology can effectively delay the corrosion of bulkheads. The membrane separation technology reduces the sediment in the ballast tank. The energy consumption is only one-third of that of other treatment systems, which is the lowest in the world, and there is no limitation on salinity, temperature, turbidity, and etc.

Overview

Treatment Technology

Mechanical filtration: High pressure back flush to ensure flux.

Membrane separation: Reducing sediments and delaying cleaning.

Nitrogen feeding and de-oxygenation: Kill organisms and prevent corrosion.

Function and Application

Treat ship ballast water to meet D-2 standard.

Effectively reduce ballast tank sediments.

Effectively reduce corrosion in ballast tanks.

Product Superiority

Our ballast water management system does not use any active substances except for the nitrogen which is harmless to the environment.

This system adopts a modular design and is applicable to both new ships and existing ships.

The backwashing water of the filter unit and the membrane separator comes from the filtered water, and there is no need to provide additional water.

Our ballast water management system has low energy consumption and very low operating costs.

The backwashing water containing high concentrations of organisms and sediments from the filter and the membrane separator can be discharged to the departure port, thus saving the cleaning cost.

Our ballast water management system injects pure nitrogen made through the pressure swing adsorption technology into the ballast tank, which has no impact on the sea water and no any by-products to affect the environment, crew and the public.

Nitrogen has a good anti-corrosion effect on the ballast tank, so it can save the ship body maintenance cost.

Our ballast water management system is easy to operate and convenient to maintain.

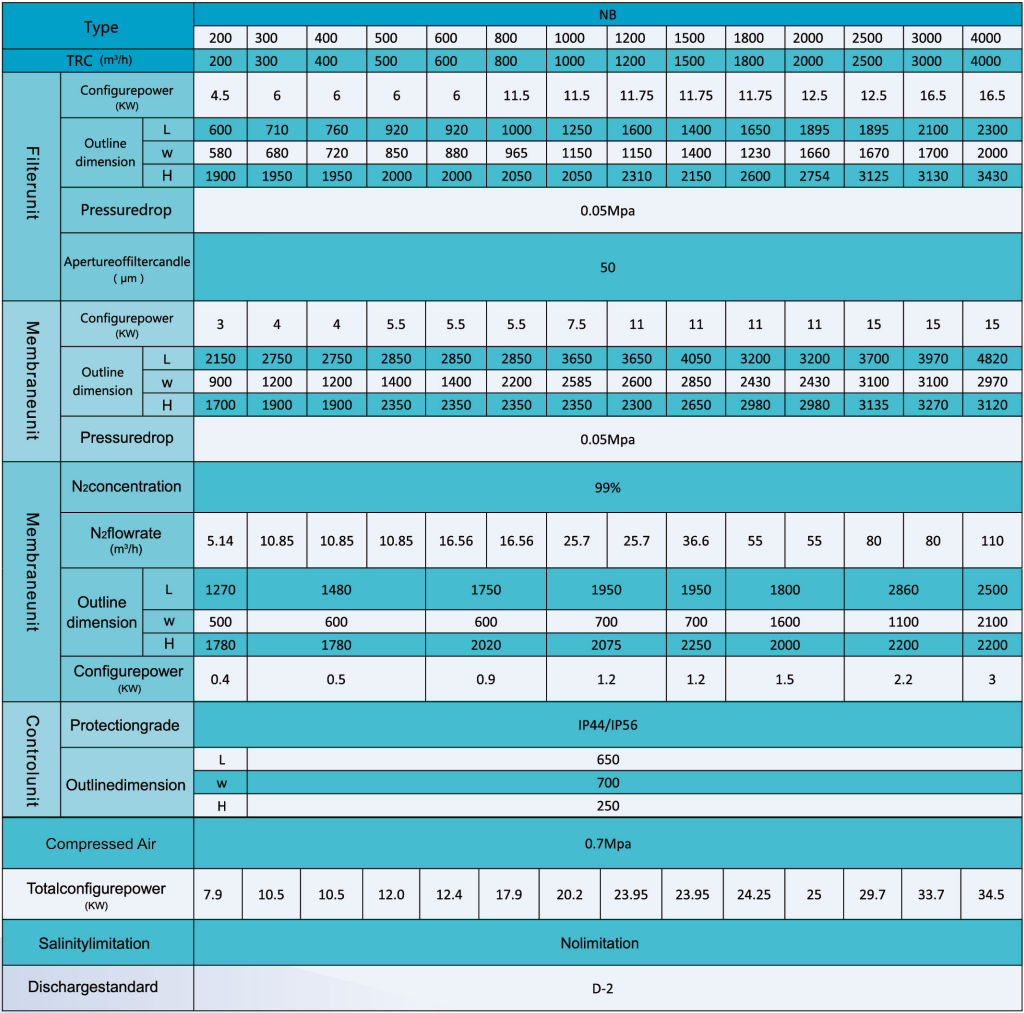

Specification and Main Technical Parameters

Note: The actual power consumption is less than 30% of the configured power. The specifications in the above table are only for reference, and we can carry out non-standard design according to the situation on the ship.

For the system with a treatment rate (TRC) greater than 1500 cubic meters per hour, it can be assembled in a parallel way. For the device to be installed in a special area, our company will provide a complete solution.

Composition

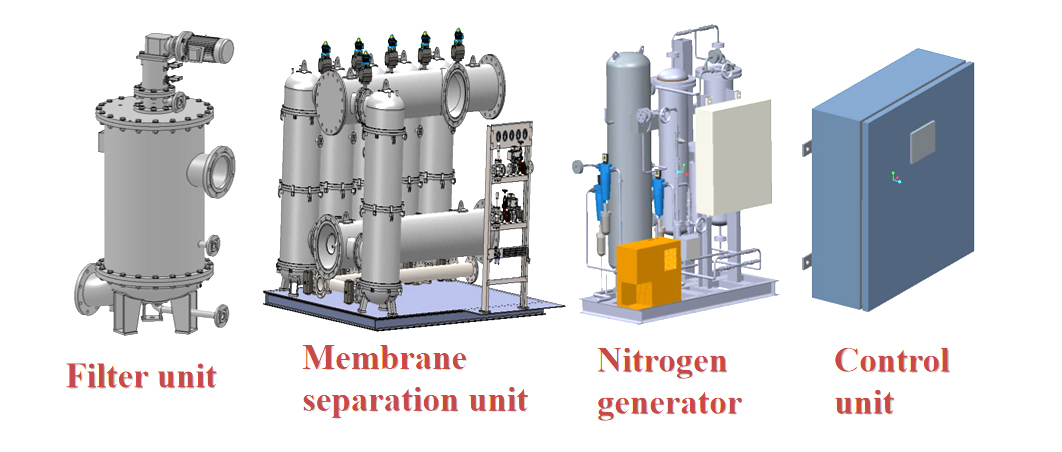

Filter Unit:

It mainly consists of actuator, transmission mechanism, back flushing pipe, blow-down pipe, filter core, back flushing pump, blow-down pump, travel switch, etc., used to remove organisms and solid particles greater than 50μm, and carry out high pressure and suction back flushing of the filter core under differential pressure or timer.

During back flushing, the actuator drives the flushing pipe and the discharge pipe to rotate and reciprocate under the control of the travel switch, the back flushing pump sucks the filtered water at high pressure to flush the filter core, and the blow-down pump sucks the solid particles after back flushing and discharge them overboard.

Membrane Separation Unit:

It is mainly consists of membrane modules, pneumatic valves, back flushing pumps, etc., removing organisms and solid particles greater than10μm, and performing gas-water mixture back flush on the membrane elements under the control of differential pressure or timer. When back flushing, the 1# membrane module inlet valve is closed, the back flushing and compressed air valve are opened, the back flushing pump is started, and the 1# membrane module is back flushed. After 30 seconds, the conversion is performed on 2# membrane module for back flushing. The back flushing process is completed after all the membrane components have been back flushed as this.

Nitrogen Generator:

The PSA nitrogen generator uses air as the material and uses molecular sieves to selectively adsorb nitrogen and oxygen. The smaller diameter gas (oxygen) diffuses faster and enters the molecular sieve more. The larger diameter gas (nitrogen) diffuses slowly and enters the molecular sieve, therefore, separate nitrogen and oxygen from the air. After a period of time, the adsorption of oxygen by the molecular sieve is balanced. According to the different adsorption capacity of the carbon molecular sieve to the adsorbed gas under different pressures, the pressure is reduced to desorb the carbon molecular sieve, which is called regeneration. The pressure swing adsorption method generally uses two columns in parallel, alternately performing pressure adsorption and decompression regeneration to obtain a continuous nitrogen flow.

Control Unit:

Automatic and manual control system operation.

Monitor the operation status of the system.

Record system operation information.

TA Certificates:

Conclusion

For additional details, please contact us! For other types of products, please feel free to contact us, or visit our Ballast Water Management System homepage to learn more!