Compacted Steel Wire Rope

About compacted steel wire rope, stranded rope in which the strands, prior to closing of the rope, are subjected to a compacting process such as drawing, rolling or swaging, resulting in a reduction in the diameter of the strand, a smoother surface of the strand, and a flatter contact line between the wires. Each layer of steel wires in the strand and between layers of the strand are in contact with each other along helical surfaces. The compacted stranded steel wire rope is based on an line contact structure.

Overview

Compacted round strand:

(1).png)

Class:

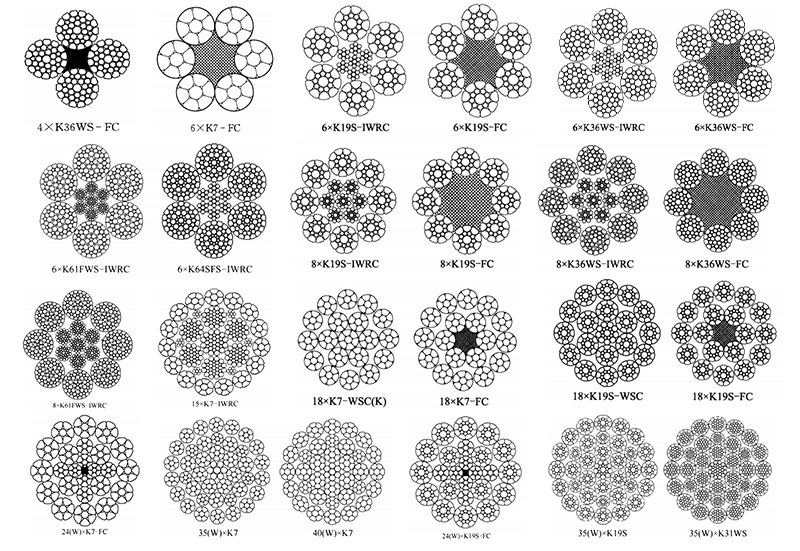

Single-layer rope:4×K19,4×K36,6×K7, 6×K19, 6×K36, 6×K61, 8×K19, 8×K36, 8×K61;

Rotation-Resistant Rope: 18×K7,18×K19, 23×K7, 24(W)×K7, 24(W)×K19, 35(W)×K7, 35(W)×K19;

Parallel-closed rope: 8×K19-PWRC(K), 8×K36-PWRC(K).

Construction cross section example:

Specification:

Tensile Strength: 1570, 1670, 1770, 1870, 1960, 2160Mpa.

Finish: Bright, Galvanized, Coated

Material: 60#, 65#, 70#, 80#Steel, SWRH62A, SWRH72A, SWRH82A.

Main application:

Compacted steel wire rope is mainly used for erect well hoisting, mine hoist, large casting, oil drilling, hoisting a large, ships, offshore installations, aerial tramway and the transport and lifting equipment.

Compacted strand wire rope characteristics:

1. The wires contact each other in helical surfaces.

2. The filling coefficient of the wires in the strand is large (generally above 0.9), and the gaps between the wires are very small.

3. The outer surface of the strand rope is very smooth.

4. The face contact circular strand structure is stable, the position of the wires inside the strand is fixed, and the structural elongation is minimal.

5. Have higher breaking strength

6. Allow the wire rope to better contact with pulleys

7. More wear-resistant and corrosion-resistant.

8. More suitable for applications requiring multi-layer winding.

9. The compacted strand wire rope twisting equipment requires a larger traction force.

Compacted strand picture:

.png)