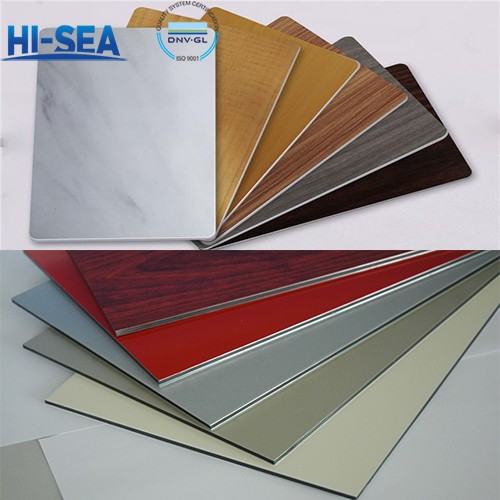

Aluminum Composite Panels

Aluminium composite panel as a new type of decorative material, with its economy, optional colour diversity, convenient construction methods, excellent processing performance, excellent fire resistance and noble quality, etc.

Overview

Composition

Aluminium composite panels are made of multi-layer materials, with high-purity aluminium alloy panels on the upper and lower layers, a non-toxic low-density polyethylene (PE) core panel in the middle, and a protective film pasted on its front. For outdoors, the front of the aluminium composite panel is coated with a fluorocarbon resin (PVDF) coating, and for indoors, the front can be coated with a non-fluorocarbon resin.

Classification

a. Fireproof board

Selection of flame-retardant core material, the combustion performance of the product to achieve flame-retardant (B1) or non-combustible (A); at the same time, other performance indicators must be in line with the requirements of the technical indicators of aluminium composite panels.

b. Antibacterial and anti-mould aluminium composite panel

The coating with antibacterial and bactericidal effect is coated on the aluminium composite panel, so that it has the function of controlling the propagation of microbial activities and eventually killing bacteria.

c. Antistatic Aluminium Composite Panel

Antistatic Aluminium Composite Panel adopts antistatic coating to coat the aluminium composite panel, the surface resistivity is below 109Ω, which is smaller than the surface resistivity of ordinary aluminium composite panel, so it is not easy to produce static electricity, and the dust in the air is not easy to adhere to its surface.

Picture of Aluminum Composite Panels