Air Balancer

The air balancer is a versatile tool that excels in precise positioning and effortless floating, ensuring smooth operations. Its adjustability is remarkable, requiring minimal effort yet delivering high efficiency. With low air consumption and oil-free operation, it maintains a clean environment while offering robust power and a sturdy build, minimizing noise levels. Its simplified design requires fewer parts, translating to reduced maintenance and an extended service life. Safety features like overload protection, air cut-off protection, and no-load protection further enhance its reliability and usability, making it an indispensable lifting device across various marine and industrial.

Overview

Principle

The pressure of compressed air can be transformed into mechanical energy through pneumatic motor, thus the output torque will drive the planetary reducer. Then the pneumatic controller will control the rotation of slewing gear to lift the load.

Technical highlights of our products

Cable Roller: reliable, durable, maintenance-free

Bearings: thrust bearings adopt dual dust-proof ball bearing

Cylinder and piston: the lubrication inside the cylinder and piston adopts imported Germany grease, when compressed air entered the cylinder, the repeat movement of pistons will become more light and smooth.

Distributing Valve: accurately control the volume of air income and outcome to reach the function of floating and balancing.

Control Handle: button-style handle can effectively and accurately control the speed and pace of ascending and descending.

Air cut-off Protection: when the air source being suddenly cut off, the centrifugal brake will automatically lock the brake, to prevent the free fall of loads.

Brake: the centrifugal brake system can effectively control the sudden fall, which will prevent the sudden ascend or descend of steel rope or hooks.

Ball Screw: the piston pushes the ball screw rotating and take the cable roller working synchronously, which will take the steel rope and lift the loads.

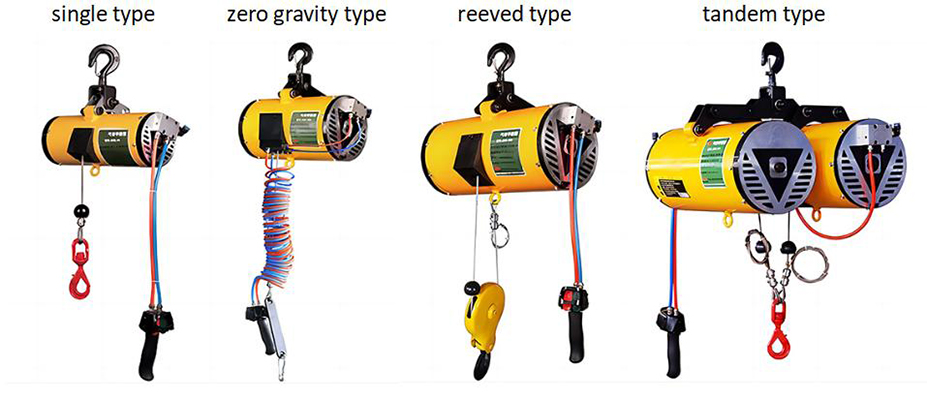

Optional type

General parameter

Working pressure: 0.7mpa

Air consumption: 0.27-0.36m³/min

Hose fming thread: Rc3/8in

Hose diameter: 10/12mm

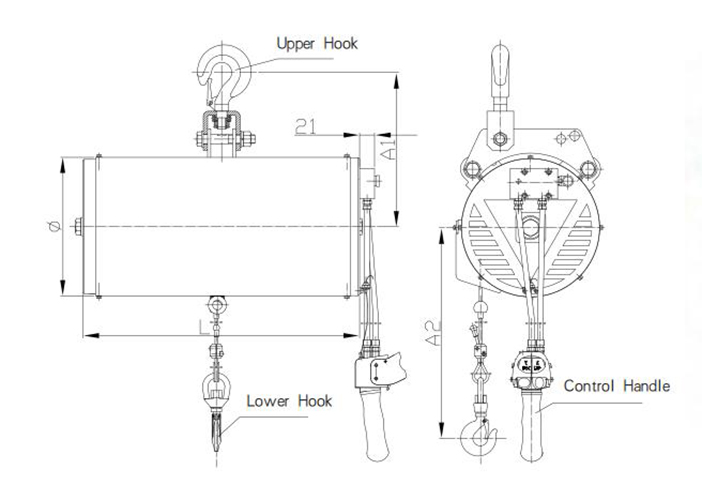

Outside drawing

Specification

Model | Unit | JMB-60 | JMB-100 | JMB-160 | JMB-220 | JMB-320 | JMB-440 |

Capacity | kg | 60 | 100 | 160 | 220 | 320 | 440 |

SWL | m | 1.4 | 1.8 | 2.3 | 1.9 | 1.1 | 0.9 |

“φ”Dimension | mm | 165 | 260 | 260 | 260 | 260 | 260 |

“L”Dimension | mm | 405 | 405 | 520 | 520 | 520 | 520 |

“A1”Dimension | mm | 245 | 290 | 290 | 290 | 290 | 290 |

“A2”Dimension | mm | 400 | 450 | 450 | 450 | 450 | 450 |

Number of wire rope | - | 1 | 1 | 1 | 1 | 2 | 2 |

Advantages of a pneumatic balancer compared with an electrical chain hoist:

Much faster lifting and lowering speeds, typically 2–6 times faster than electric hoists

“Float” function for easy and precise load positioning

Extremely high duty cycle, suitable for continuous 24-hour operation

Powered by compressed air, ensuring spark-free and safer operation

Screw-driven mechanism provides smooth, vibration-free lifting and lowering, with stepless speed control