1.25m3/H Marine Double Reverse Osmosis Watermakers

The marine double reverse osmosis watermaker adopts the internationally advanced reverse osmosis technology and is formed through systematic optimization design.

We have carried out special designs according to the particularity of ship applications. It has the characteristics of small volume, light weight, less floor space, convenient installation and strong adaptability. It is applicable to offshore operation platforms, oil tankers, etc. The equipment is convenient for operation and maintenance. As long as seawater and electricity are provided, it can produce water after starting. The equipment has a high desalination rate, stable performance, is safe and reliable, and has a novel and ingenious design.

This system can effectively remove harmful components such as inorganic salts, heavy metal ions, organic bacteria and germs in seawater, and desalinate seawater into fresh water.

Application scope: The water production is 1250L/hour. The produced fresh water is used to supply the freshwater tank, drinking water tank, cooling water tank and distilled water tank on the ship, meeting the usage requirements of domestic water and equipment water on the ship. Contact email <hs10@cqhisea.com>

Overview

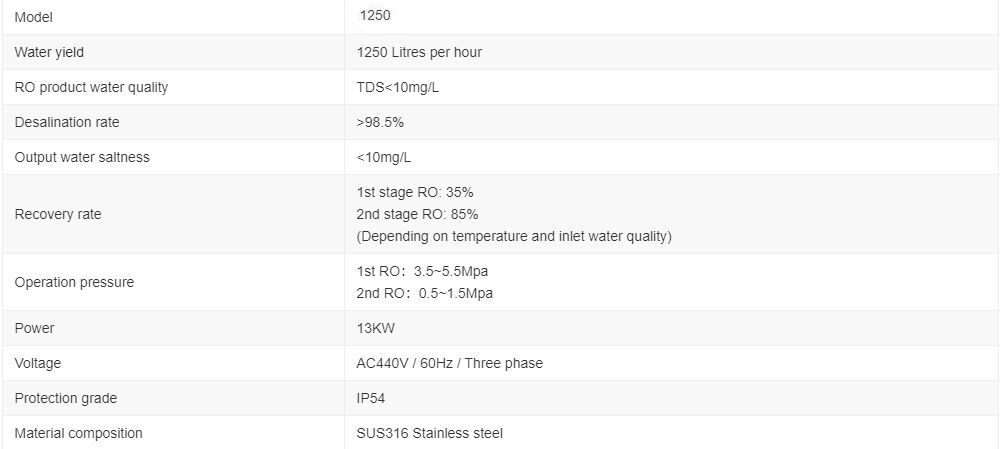

Product Parameters

Note:

1. The amount of water produced refers to the amount of water produced under the conditions of an inlet water temperature of 25 ° C, a salt content of 35,000 mg/L, and an operating pressure of 5 MPa.

2. Equipment can be customized according to customer requirements.

System Functions

1. High-pressure discharge. When the outlet pressure of the high-pressure pump exceeds 6.2 MPa, the equipment automatically shuts down for protection and emits audible and visual alarms.

2. Low-pressure shutdown protection. When the pretreatment water supply is insufficient and the inlet pressure of the high-pressure pump is lower than 0.05 MPa, the automatic stop protection action is triggered and audible and visual alarms are emitted.

3. When the salt content of the fresh water exceeds the specified value, the unqualified fresh water is automatically discharged and an alarm signal is sent out.

4. The pretreatment is equipped with a manual multi-way valve, which can perform large-flow backwashing and full washing.

5. Configure a reverse osmosis membrane cleaning system to perform physical cleaning, chemical cleaning and fluid replenishment on the reverse osmosis membrane module.

Main Accessories

●Feed water pump: SUS316, CNP brand

●Multimedia filter: Ø600x1650mm, FRP, 1 piece

●Precision filter: 20”x 5μm, FRP, 1 piece

●High-pressure pump: SUS316, Taiwan Diamond / PINFL / CNP brand

●Reverse osmosis membrane: 400, American DOW/ TORAY/ HYDRANAUTICS brand

●Membrane shell: 1000PSI (3 pieces, FRP), 300PSI (2 pieces, stainless steel)

●Rinse tank: Matched with the system

●CIP chemical cleaning device: Matched with the system

●Conductivity meter: Creation

●Electrical components: Schneider brand

Equipment List

1. Water treatment equipment

2. User manual, operation video

3. Final documents (product certificate, factory test report, packing list, equipment drawings)

4. Other consumable accessories

Conclusion

Thank you for browsing through the entire text. I hope you have gained a certain understanding of the Marine Double Reverse Osmosis Watermakers. If you have purchasing needs in related aspects, you can visit the homepage of our seawater desalination plant to learn about it, or contact us directly!