Working Principle of Marine Ballast Water Treatment System

In the global shipping system, ship ballast water is a "balance weight" for maintaining navigation stability, but it has also become the main carrier of marine alien species invasion. A single large merchant ship can carry tens of thousands of tons of ballast water per voyage. Plankton, bacteria and other organisms carried in the water, if entering new sea areas with the ship's navigation, may disrupt the local ecological balance and lead to a sharp decline in biodiversity. The Marine Ballast Water Treatment System (BWTS) is designed to solve this problem. Its core principle is to kill or remove harmful organisms in the ballast water through physical or chemical means when the ballast water is injected into or discharged from the ship, ensuring that the discharged water meets the "biological compliance standards" specified in the International Maritime Organization (IMO) Ballast Water Management Convention.

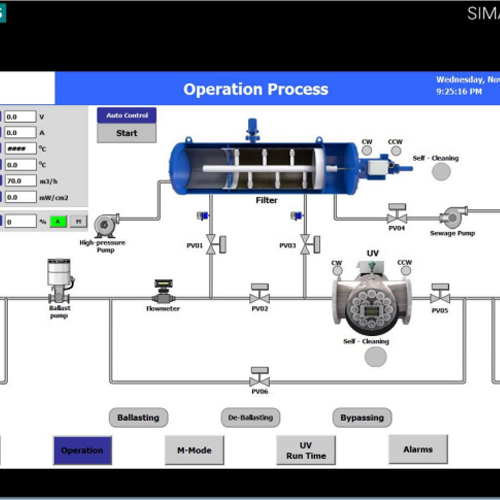

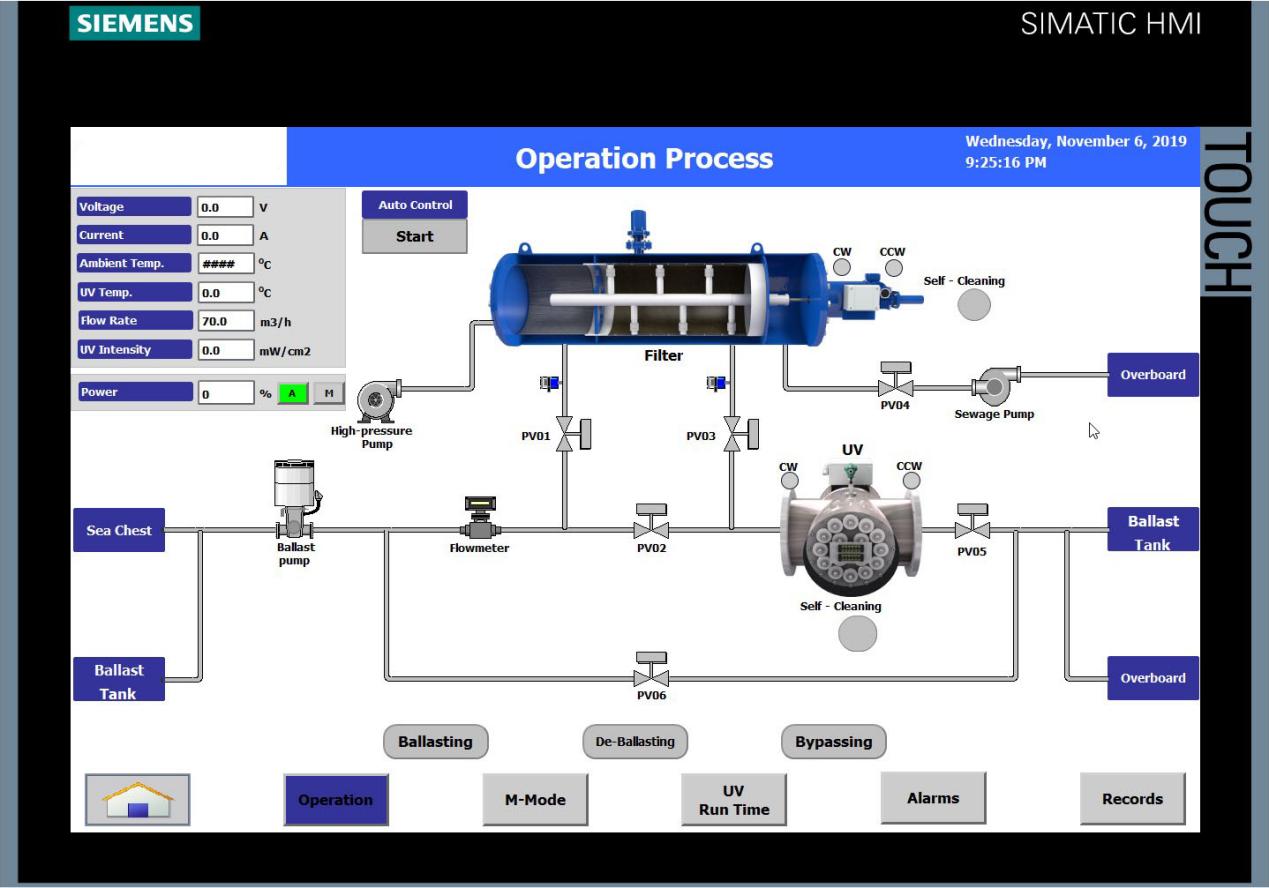

Current mainstream ballast water treatment systems, regardless of the technical path adopted, follow the three-stage core process of "Pretreatment - Main Treatment - Monitoring".

Overview

Pretreatment

The pretreatment link is the "first line of defense" for the stable operation of the system. It mainly removes large-particle impurities (such as sediment and algae residues) from the water through self-cleaning filters, with the filtration precision usually controlled at 50-100 micrometers. This step not only prevents subsequent processing equipment from being blocked but also reduces the "biological load" in the main treatment stage. If there are too many impurities, they will wrap harmful microorganisms and reduce the efficiency of subsequent treatment. Some systems also add deoxygenation devices during pretreatment to inhibit the activity of aerobic microorganisms by reducing the dissolved oxygen content in the water, paving the way for subsequent treatment.

Main Treatment

The main treatment link is the key to achieving "biological inactivation", which is mainly divided into two categories in the industry: physical methods and chemical methods.

Physical Methods

Among physical methods, ultraviolet (UV) irradiation technology is the most widely used. When ballast water passes through a specially designed UV reaction chamber, high-intensity ultraviolet rays destroy the DNA structure of microorganisms, making them lose their reproductive capacity without producing chemical residues. However, this technology has high requirements for water transparency. If the water turbidity is too high, ultraviolet rays will be absorbed by impurities, requiring strict pollution control in the pretreatment link. Another type of physical technology is electrolysis, which generates oxidizing substances such as sodium hypochlorite and ozone by electrolyzing seawater. It uses their strong oxidizing properties to destroy the cell membranes of microorganisms, suitable for seawater ships. However, the concentration of electrolysis products needs to be controlled to avoid corrosion of ship pipelines.

Chemical Methods

Chemical methods are centered on "injection of active substances", with common ones including oxidizing biocides (such as sodium hypochlorite) and non-oxidizing biocides (such as quaternary ammonium salts). When the ship injects ballast water, the system automatically calculates the dosage according to the water flow rate, allowing the biocide to fully mix with the ballast water and complete microbial inactivation within a preset time. To avoid secondary pollution to the marine environment caused by chemical residues, some systems add "neutralizers" before drainage to decompose excess biocides into harmless substances. It is worth noting that chemical methods need to strictly control the dosage of chemicals. Too low a dosage cannot meet the standards, while too high a dosage may harm marine organisms. Therefore, real-time concentration monitoring devices need to be matched.

Comparison between Physical and Chemical Methods:

Comparison Dimension | Physical Methods | Chemical Methods |

Technical Principle | Directly destroy microbial structures or limit their living environment through physical means (filtration, ultraviolet rays, ultrasonic waves, heating, etc.). | Use the strong oxidizing properties of chemical agents (chlorine, ozone, hydrogen peroxide, etc.) to kill microorganisms, or generate disinfectants by electrolyzing seawater. |

Typical Methods | 1. Filtration: Mechanical filters intercept large-particle organisms (precision usually ≤50μm). 2. Ultraviolet (UV): 254nm wavelength destroys DNA. 3. Ultrasonic waves: Acoustic energy generates cavitation effect to destroy cell structures. 4. Heating: Heat to 40-50°C to inactivate organisms. | 1. Chlorination: Inject chlorine or sodium hypochlorite. 2. Ozone treatment: Strong oxidation decomposes organic matter and microorganisms. 3. Electrolysis: Electrolyze seawater to generate sodium hypochlorite. 4. Seakleen method: Use peroxides and catalysts. |

Treatment Effectiveness | - Filtration: Only removes visible particles, requiring combination with other methods. - Ultraviolet: Inactivation rate >90% when light transmittance is good, but greatly affected by water quality (e.g., iron ions, suspended solids blocking). - Ultrasonic waves: Effective for plankton, but limited effect on dormant spores. - Heating: Requires more than 2 hours, high energy consumption and unable to treat spores. | - Chlorination: Biological mortality rate is about 80%, but residual chlorine needs to be neutralized. - Ozone treatment: Fast and efficient (within minutes), but high requirements for water quality. - Electrolysis: Meets IMO D-2 standards, but needs to control salinity and temperature. |

Equipment Cost | - Ultraviolet: Medium (high cost of lamp replacement). - Filtration + Ultraviolet: The average price of the system for 100,000 DWT ships in 2024 is about 1.85 million yuan. - Ultrasonic waves: Low (small equipment power). | - Electrolysis: High (requires complex pipelines and corrosion-resistant materials). - Ozone treatment: High (requires ozone generator and decomposition system). - Chlorination: Medium (requires chemical storage equipment). |

Operating Cost | - Ultraviolet: Low energy consumption (about 0.5-1.5kWh/m³), but short lamp life (about 1000 hours). - Ultrasonic waves: Extremely low energy consumption (e.g., 3 sensors only 60W). | - Electrolysis: High energy consumption (needs to heat seawater) and regular supplement of chemical agents. - Ozone treatment: Medium energy consumption, but continuous ozone injection is required. - Chlorination: High chemical cost (e.g., sodium hypochlorite is about $2-$4 per liter) and needs to neutralize residues. |

Maintenance Complexity | - Ultraviolet: Regular lamp cleaning and filter replacement are required. - Filtration: Frequent backwashing and easy filter clogging. | - Electrolysis: Need to maintain electrodes and monitor water quality parameters (salinity, pH). - Ozone treatment: Regular inspection of ozone generator and decomposition system is required. - Chlorination: Need to handle chemical leakage risks and storage safety. |

Environmental Impact | - No chemical residues, but UV lamps contain mercury and require special treatment. - Ultrasonic waves: May generate noise affecting crew health. | - Secondary pollution risk: Chlorination generates carcinogens such as trihalomethanes (THMs), and incomplete ozone decomposition may release harmful gases. - Residues need to be neutralized: For example, electrolysis requires adding sodium bisulfite to remove residual chlorine. |

Regulatory Compliance | - Filtration + Ultraviolet: Mainstream solution, meeting IMO D-2 standards. - Ultrasonic waves: Need to be combined with other methods to meet strict requirements. | - Electrolysis: Widely used, but needs to comply with IMO's limit on Total Residual Oxidant (TRO) (≤0.5mg/L). - Ozone treatment: Decomposition efficiency needs to be verified to avoid excessive emissions. |

Application Scenarios | - Ocean-going ships: Stable water quality, good UV effect. - Sensitive water areas: Avoid chemical pollution (e.g., polar regions, enclosed ports). | - Coastal navigation: Rapid treatment of highly polluted ballast water. - Retrofit of old ships: Small equipment size, easy integration. |

Technical Trends | - Intelligence: Combine sensors to automatically adjust treatment parameters (e.g., UV dosage). - Combined technology: Filtration + UV + ultrasonic waves to synergistically improve effectiveness. | - Green chemistry: Develop low-toxicity agents (e.g., hydrogen peroxide) and closed-loop treatment systems. - Electrolysis optimization: Reduce energy consumption and material corrosion. |

Monitoring

The monitoring link is the "final checkpoint" to ensure treatment effectiveness. The system real-time collects ballast water samples before and after treatment, and monitors water quality indicators and biological inactivation effects through turbidity sensors, residual chlorine detectors, microbial activity detectors and other equipment. If an indicator is found to be non-compliant (e.g., too low residual chlorine concentration, excessive microbial activity), the system will automatically trigger an alarm and even suspend ballast water discharge until the problem is solved. Some high-end systems also have data storage functions, which can record the time, water volume, indicator data of each treatment, facilitating port state inspection and retrieval.

The monitoring link is the "final checkpoint" to ensure treatment effectiveness. The system real-time collects ballast water samples before and after treatment, and monitors water quality indicators and biological inactivation effects through turbidity sensors, residual chlorine detectors, microbial activity detectors and other equipment. If an indicator is found to be non-compliant (e.g., too low residual chlorine concentration, excessive microbial activity), the system will automatically trigger an alarm and even suspend ballast water discharge until the problem is solved. Some high-end systems also have data storage functions, which can record the time, water volume, indicator data of each treatment, facilitating port state inspection and retrieval.

From "passive discharge" to "active governance", the popularization of marine ballast water treatment systems marks a key step in the transformation of the shipping industry towards "ecologically friendly". With technological iteration, new-generation systems are developing in the direction of "low energy consumption, intelligence, and multi-scenario adaptation"—such as dual-mode systems that can handle both seawater and freshwater, and intelligent systems that realize dynamic dosing combined with AI algorithms. They can not only reduce ship operation costs but also further improve the precision of ecological protection. Today, with the increasingly urgent global demand for marine ecological protection, this "ecological guardian" is becoming a "standard configuration" for every ocean-going ship, building a solid barrier for protecting the biodiversity of the blue planet.