Marine Weather-tight Doors and Watertight Doors

Marine weather-tight doors and watertight doors are two types of sealing doors with different functions on ships. The main differences are reflected in design purposes, performance requirements, installation locations, regulations, and standards, as follows:

Overview

1. Definitions and Core Functions

Weather-tight Doors: Their core function is to resist the invasion of the external environment such as wind, rain, and splashing water from waves during the ship's navigation, preventing rainwater, spray, or mist from entering the cabins and ensuring the dryness inside the cabins. They are not required to withstand hydrostatic pressure and only need to prevent "flowing water" (such as rainwater and splashing water) from intruding under normal navigation conditions (non-damaged state).

Watertight Doors: Their core function is to prevent water from spreading between different cabins when the ship is damaged or a cabin is flooded, maintaining the ship's buoyancy and stability. They are the "life-saving devices" of the ship. They need to maintain absolute sealing under specific hydrostatic pressure and can prevent water from seeping to the other side even if one side of the cabin is flooded.

STEEL WEATHERTIGHT DOOR STEEEL WATERTIGHT DOOR

2. Performance Requirements

Sealing Performance of Weather-tight Doors: They only need to resist "non-pressure water" (such as rainwater and splashing waves), with a relatively simple sealing structure (such as rubber sealing strips) and do not need to withstand water pressure.

Strength of Weather-tight Doors: They only need to meet the impact of wind and rain during normal navigation, with relatively low structural strength.

Sealing Performance of Watertight Doors: They need to withstand a specific hydrostatic pressure, with a more complex sealing structure (such as multiple metal or high-strength rubber seals, combined with a pressing device).

Strength of Watertight Doors: They need to withstand the load caused by water pressure. The door panels and door frames are usually made of high-strength steel and have a thick structure.

3. Installation Locations

Weather-tight Doors: They are mainly installed in the superstructures on the open decks of ships (such as the entrances and exits of the wheelhouse, crew cabins, and storage cabins) or the openings of non-watertight cabins on the decks, used to isolate the external wind and rain.

Watertight Doors: They must be installed on the watertight bulkheads below the ship's main deck (the vertical structures separating different watertight cabins) and are usually located in the areas below the subdivision load line (such as between cargo holds, between the engine room and cargo holds, and the passages of double-bottom cabins), used to block the water flow when a cabin is flooded.

4. Regulations and Standards

Weather-tight Doors: The requirements are relatively loose, mainly meeting the basic requirements of "preventing the invasion of wind and rain" in the ship construction specifications, without mandatory hydrostatic pressure tests or emergency closing requirements.

Watertight Doors: They are strictly regulated by the International Maritime Organization (IMO) "International Convention for the Safety of Life at Sea" (SOLAS) and need to meet: hydrostatic pressure tests (such as remaining leak-free for 30 minutes under the specified pressure).

5. Appearance

Ordinary Weather-tight Doors: They have 4 - 6 locking devices.

Ordinary Watertight Doors: They have 6 - 8 locking devices.

6. Rubber Sealing Strips

The rubber sealing strips of marine weather-tight doors and watertight doors are the core components to ensure their sealing performance. The differences between the two are mainly reflected in material strength, structural design, water pressure resistance, and applicable scenarios, ultimately serving the essential functional differences of "preventing wind and rain" and "resisting water pressure". The specific comparisons are as follows:

6.1 Different Core Functional Goals

Sealing Strips of Weather-tight Doors: They only need to block splashing rainwater, waves, and strong winds and do not need to withstand continuous water pressure. The core goal is to "prevent leakage" (in a non-high-pressure environment).

Sealing Strips of Watertight Doors: They need to withstand continuous water pressure (usually ≥ 0.21 MPa, about the pressure at a depth of 21 meters) when the ship is damaged and a cabin is flooded. The core goal is to "resist water pressure leakage", which is directly related to the ship's buoyancy and safety.

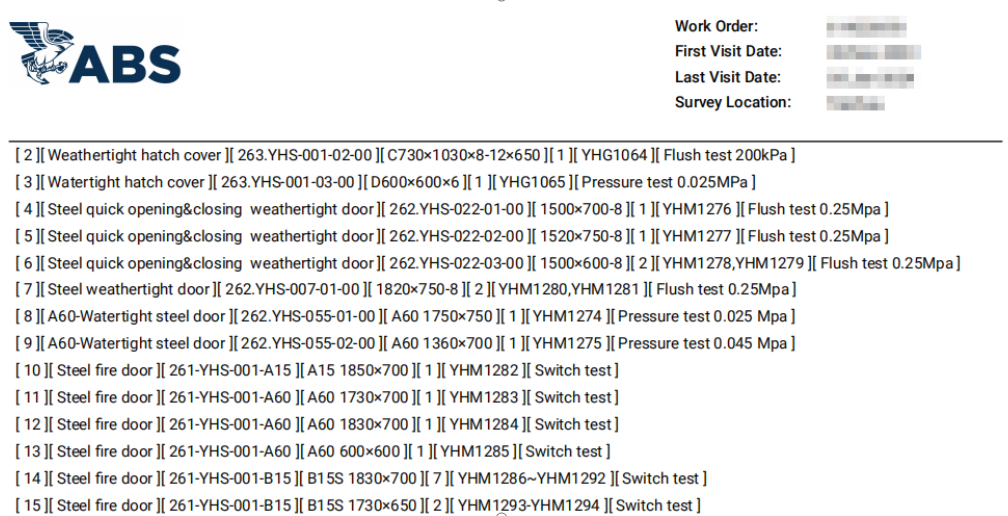

Weather-tight Doors flushing test Watertight Doors hydrostatic pressure test

6.2 Differences in Material Selection

Name | Sealing Strips of Weather-tight Doors | Sealing Strips of Watertight Doors |

Base Rubber | Mainly EPDM (Ethylene Propylene Diene Monomer) | Mainly CR (Chloroprene Rubber), NBR (Nitrile Butadiene Rubber), or composite rubber (such as CR + EPDM) |

Material Characteristics | Strong weather resistance (anti-ultraviolet and ozone), moderate elasticity, and low cost | Stronger oil resistance and aging resistance, higher hardness (Shore hardness 60 - 80, usually 50 - 70 for weather-tight doors), tear strength ≥ 15 kN/m (about 10 kN/m for weather-tight doors) |

Reinforcing Components | No or a small amount of fillers (such as carbon black) | Many add fabric skeletons (such as nylon cloth and wire mesh) or metal reinforcement layers to improve the anti-deformation ability |

Applicable Medium | Rainwater, air, and a small amount of splashing seawater | Long-term contact with seawater and oil stains and need to be resistant to chemical corrosion |

The sealing strip materials need to match the environmental pressure and medium they bear. There are significant differences in the types of rubber and reinforcing components between the two:

Reason: Watertight doors need to maintain a stable shape under water pressure. If the hardness is too low, they are easily deformed by water pressure, and if the tear strength is insufficient, they may break under pressure. Weather-tight doors focus more on not aging after long-term exposure to the atmosphere.

6.3 Differences in Structural Design

The cross-sectional structure of the sealing strips directly affects the sealing effect. Watertight doors have a more complex structure due to the need for "self-tightening sealing" (the greater the water pressure, the tighter the sealing).

Sealing Strips of Weather-tight Doors: They are mostly single-channel seals with a simple cross-section (such as circular, rectangular, and D-shaped). They rely on the mechanical pressure when the door is closed to fit the door frame and have no "self-tightening function". For example, a circular cross-section (diameter 10 - 20 mm) fills the gap through extrusion deformation and is suitable for non-high-pressure environments.

Sealing Strips of Watertight Doors: They are mostly multi-channel seals (2 - 3 channels) with a cross-section in the shape of "lip", "T", "wedge", or "U", and are designed with a "self-tightening structure":

First Seal: The main seal with a "lip" cross-section. The lip faces the water pressure direction. The greater the water pressure, the closer the lip fits the door frame, enhancing the sealing.

Second Seal: The auxiliary seal with a "rectangular" or "semicircular" cross-section, preventing leakage when the first seal fails.

Some high-end models have a "pressure relief groove" to prevent the sealing strip from being over-deformed due to excessive pressure.

6.4 Differences in Water Pressure Resistance and Test Standards

The performance of the sealing strips needs to be verified through strict tests, and there are significant differences in the test standards and indicators between the two.

Sealing Strips of Weather-tight Doors: The test standard is only to pass the "water flushing test" (such as ISO 17712). Spray water on the door with a water pressure of 0.25 MPa (about 2.5 meters of water head) for 30 seconds without leakage. A small amount of "sweating" (surface wetting but no dripping) is allowed, and there is no requirement for continuous water pressure testing.

Sealing Strips of Watertight Doors: The test standard needs to comply with the SOLAS Convention or IMO A.1108 (30) Resolution and pass the "hydrostatic pressure test": maintain for 30 minutes under a water pressure of 0.05 MPa without deformation or leakage (no water droplets are allowed to seep out). In addition, the sealing strips of watertight doors are required to maintain elasticity in high-temperature (80°C) and low-temperature (-30°C) environments, and their performance remains unchanged after 100 pressure cycle tests (from 0 to 0.21 MPa).

6.5 Differences in Installation and Fixing Methods

To prevent the sealing strips from falling off under pressure, the fixing methods of the two are also different.

Sealing Strips of Weather-tight Doors: They are mostly fixed by the "groove type" (the door frame has a groove, and the sealing strip is embedded) or simple bonding (fixed with glue) and do not need to withstand tension.

Sealing Strips of Watertight Doors: They must be fixed by "embedding + bolt pressing" or "vulcanization fixing" (the rubber and the door frame are integrally formed through high-temperature vulcanization) to ensure that they will not be "flushed out" under water pressure. For example, the edge of the sealing strip is designed with a flange, and the flange is pressed by the bolts on the door frame, with a fixing strength ≥ 5 kN/m (about 2 kN/m for weather-tight doors).

6.6 Differences in Typical Application Scenarios

Sealing Strips of Weather-tight Doors: They are used in non-watertight cabins such as superstructures on the deck, crew cabins, and cargo hold ventilation openings. For example, the deck passage doors of container ships have a service life of about 3 - 5 years (due to exposure to the atmosphere, the main aging factor is ultraviolet rays).

Sealing Strips of Watertight Doors: They are used in watertight cabins such as cargo hold bulkheads, engine rooms, and ballast tanks. For example, the watertight doors of the vehicle decks of ro-ro passenger ships have a service life of about 5 - 8 years (due to long-term contact with seawater, they need to be corrosion-resistant, and the door frame pressing structure needs to be completely removed when replacing).

Core Difference Comparison Table

Name | Sealing Strips of Weather-tight Doors | Sealing Strips of Watertight Doors |

Core Goal | Prevent wind, rain, and splashing water | Resist continuous water pressure (≥ 0.21 MPa) |

Material | Mainly EPDM, with lower hardness (50 - 70 Shore) | Mainly CR/NBR, containing a reinforcing skeleton, with higher hardness (60 - 80 Shore) |

Structure | Single-channel,simple cross-section (circular/rectangular) | Multi-channel, lip-shaped/wedge-shaped (self-tightening design) |

Water Pressure Resistance Test | Flush with 0.25 MPa for 30 seconds, allowing a small amount of wetting | Hydrostatic pressure of 0.05 MPa for 30 minutes, zero leakage |

Fixing Method | Groove or bonding | Vulcanization fixing or bolt pressing |

7. Price

The unit price of ordinary steel watertight doors is 0.5 times or even more than twice that of ordinary steel weather-tight doors.