Effects of Oversized or Undersized Marine Pump Selection

As core equipment in a ship's power system, auxiliary systems, and safety systems, the rationality of marine pump selection is directly related to the ship's operational efficiency, safety, and economy. During the ship design and construction phase, the selection of marine pumps must accurately align with design requirements—it should not only meet the functional needs of various ship systems but also operate as close as possible to the Best Efficiency Point (BEP) to achieve efficient and stable operation.

In the ship design process, to address various uncertainties that may arise during navigation, design institutes often incorporate excessive safety margins. However, such excessive redundancy not only accelerates the wear of flow-through components but also shortens the service life of the entire system, which is counterproductive to the long-term stable operation of the ship.

Overview

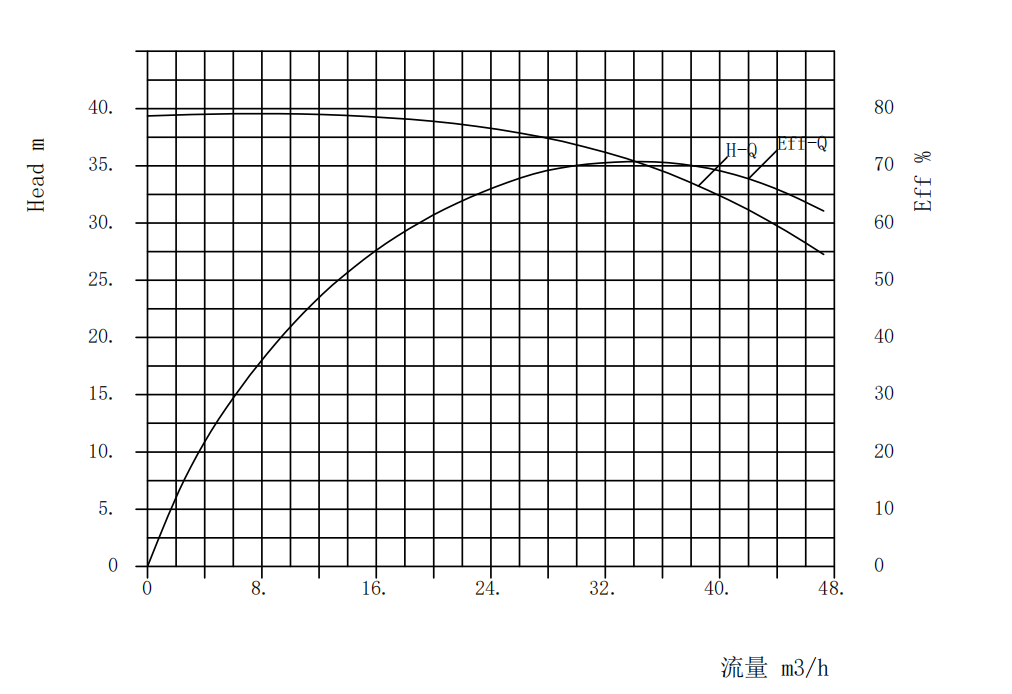

When selecting a marine pump system, the core goal is to meet the pressure (head) and flow rate requirements of the application—this applies to cooling water systems, fuel transfer systems, and other marine pump systems alike. The flow rate required by the system is used to determine the total dynamic head (TDH) of the pump, which in turn serves as a basis for comparing the performance curves of various optional pump types. Oversized or undersized pump selection can have severe impacts on the system; therefore, identifying the accurate operating point during the selection process is crucial.

1. Specific Impacts of Oversized or Undersized Selection

If the selected pump is undersized, the flow rate in the system will fail to meet requirements; conversely, an oversized pump will deliver a flow rate exceeding the system's needs. On the surface, if the pump's operating point can be corrected by simply adjusting system valves, the impact on the system may seem minimal. However, from the perspective of pump efficiency, the consequences of improper selection become prominent.

The Best Efficiency Point (BEP) is the ideal operating state of a pump—at this point, the maximum proportion of energy driving the pump is transferred to the fluid. When the pump's operating point deviates from the BEP, the most direct consequence is a drop in efficiency, requiring the pump to consume more driving power. The energy not transferred to the fluid is released in other forms such as heat and vibration, leading to increased vibration and heat generation as efficiency decreases. In the short term, this impact may not be significant, but the greater the deviation of the pump's operating point from the BEP, the more severe the negative effects.

Centrifugal pumps are generally recommended to operate within the range of 80% to 110% of the BEP to avoid adverse effects. If the operating point exceeds 110% of the BEP, insufficient Net Positive Suction Head (NPSH) margin may cause cavitation, along with the risk of equipment damage due to vibration and heat. Conversely, if the operating point falls below 80% of the BEP, issues such as pump seizure, low-flow cavitation, internal recirculation, and high temperatures may occur. Over the long term, such improper operation will lead to rising maintenance costs, increased energy consumption, and a significant reduction in the pump's service life.

2. How to Avoid Oversized or Undersized Selection

During selection, full consideration should be given to the extreme operating conditions of the ship during actual navigation. It is essential to ensure that the flow rate and head parameters under extreme conditions align with the BEP of the pump characteristic curve. This ensures the pump operates efficiently and reduces wear on flow-through components. If the system's requirements change frequently, equipping the pump with a variable-frequency motor can be considered to keep the pump operating within the ideal range at all times.

3. Conclusion

Designing a system that meets operational requirements is crucial; however, in system design, "bigger is better" is not always the case. A scientific and rational design not only reduces material and installation costs during the system construction phase but also effectively avoids additional wear on marine pump components, ensuring the economical and efficient operation of the ship.