Differences Between Marine Hydraulic Anchor Windlasses and Marine Electric Anchor Windlasses

As an very important equipment for all ships, anchor windlasses are installed on the deck of every vessel. The two most common types are hydraulic anchor windlasses and electric anchor windlasses. To help users select the anchor windlass that best suits their specific ship, we elaborate on the differences between hydraulic and electric anchor windlasses as follows.

Overview

1. Core Differences

The core differences between the two types of anchor windlasses lie in their power source, power transmission method, transmission structure, and control method.

Hydraulic Anchor Windlass | Electric Anchor Windlass | |

Power Source | The ship's central hydraulic system or an independent hydraulic power unit | Electricity supplied by the ship's main switchboard or emergency switchboard |

Power Transmission Method | High-pressure hydraulic oil is transmitted to the hydraulic motor on the windlass via pipelines | Electrical energy is transmitted to the electric motor on the windlass via cables |

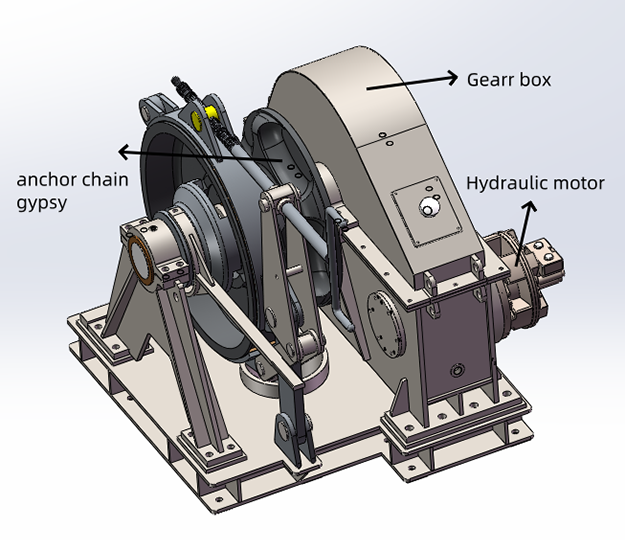

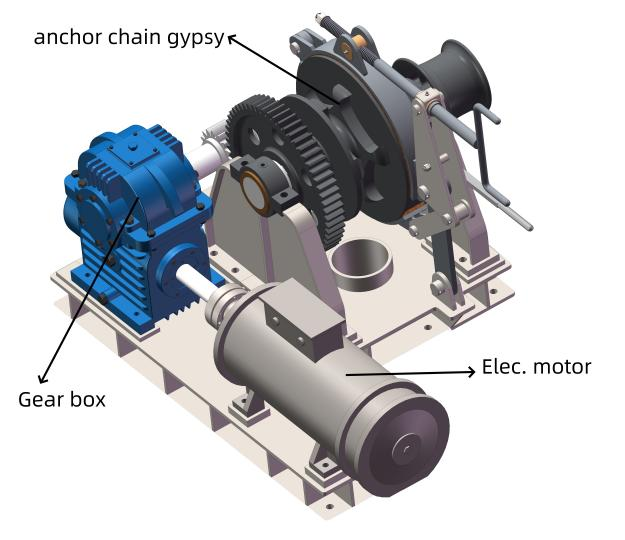

Transmission Structure | Hydraulic Motor → Gearbox → Anchor Chain Wheel | Electric Motor → Gearbox → Anchor Chain Wheel |

Control Method | The direction, flow rate, and pressure of hydraulic oil are adjusted by operating a hydraulic manual proportional valve, thereby controlling the rotation direction and speed of the hydraulic motor. | The electric control system is used to control the start, stop, forward/reverse rotation, and speed of the electric motor. |

|  |

2. Advantages and Disadvantages of each type anchor windlass

The advantages and disadvantages of the two type anchor windlasses are directly related to their core structures, and a comprehensive evaluation must be conducted based on the ship type, ship tonnage, and operating scenario.

Advantages | Disadvantages | |

Hydraulic anchor Windlass | 1. Large and stable output torque: The hydraulic system can achieve large torque output by adjusting pressure and flow rate, with minimal torque fluctuation when the load changes. 2. High speed regulation precision: Stepless speed regulation is realized via a manual proportional valve, ensuring smooth anchor lifting /anchor dropping processes and precise control of anchor chain retrieval and deployment speed. 3. Strong overload protection capability: The hydraulic system has a built-in "overload unloading" feature, which prevents damage caused by sudden overload. 4. Flexible layout: The hydraulic power unit can be installed away from the windlass itself, and the windlass body has a compact structure, making it suitable for ships with limited deck space. 5. The hydraulic motor itself can operate in flammable, explosive, high-temperature, and humid environments, and it is relatively easy to meet explosion-proof requirements. | 1. Complex system with multiple fault points: It relies on precision components such as hydraulic pumps, oil pipes, seals, and hydraulic valves. Oil leakage and oil contamination are common faults, and maintenance is difficult. 2. Low energy efficiency: The hydraulic system has pump efficiency loss, pipeline pressure loss, valve port throttling loss, and motor efficiency loss, so its total efficiency is usually lower than that of the electric system. 3. High maintenance costs: Regular replacement of hydraulic oil and seals is required, and the purchase cost of hydraulic components is high. |

Electric Anchor Windlass | 1. High energy efficiency ratio: The motor drives directly, resulting in minimal power transmission loss. 2. Simple structure and high reliability: The core components are the electric motor and gearbox; and fault points are concentrated in the electrical system, making troubleshooting easy. 3. Low maintenance costs: core maintenance includes motor insulation testing and gearbox lubricating oil replacement, and the cost of spare parts is low. 4. Fast start response: The response time of the motor from a stationary state to rated speed is shorter than that of the hydraulic windlass. 5. Easy integration into automated systems: Electric windlasses can be more easily connected to integrated automation systems. | 1. Poor overload adaptability: When the motor is overloaded, the winding is prone to burning out due to excessive current. 2. Limited speed regulation range: Ordinary asynchronous motors use stepped speed regulation; although variable-frequency motors can achieve stepless speed regulation, their torque attenuates significantly at low speeds, and their cost is relatively high. 3. Layout limitations: The motor is relatively large and must be installed close to the windlass body, requiring more deck space. 4. Harsh environment adaptability: The electric motor and its electrical control system require a high degree of protection and insulation to prevent damage from moisture and salt spray. |

3. Summary and Selection Recommendations

(1) Hydraulic Anchor Windlasses

Their core advantages lie in excellent overload protection capability and adaptability to scenarios with limited space or explosion-proof requirements (for the motor body). Their main disadvantages are low efficiency, complex system, high maintenance requirements, and risk of leakage. They are suitable for:

A.Occasions requiring extreme overload protection (e.g., tugs, engineering ships).

B.Locations with extremely limited installation space.

C.Ships already equipped with a powerful and reliable central hydraulic system.

(2) Electric Windlasses

Their core advantages are high energy efficiency, relatively simple system, convenient maintenance, and no risk of hydraulic oil leakage. With the adoption of variable frequency drive (VFD) technology, their speed regulation performance and torque control precision have been greatly improved. Their main disadvantages are slightly inferior extreme overload protection compared to hydraulic windlasses and high protection requirements for harsh electrical environments. They are suitable for:

A.Ships pursuing high energy efficiency and low operating costs.

B.Scenarios where easy maintenance and no leakage are key considerations.

C.Ships with a strong and stable power grid.

D.Applications requiring integration with automated control systems.