Structure of stern tube sealing device

If open lubrication is used for the stern tube bearings, a sealing device only needs to be installed at the bow end of the stern tube; If closed lubrication is used, sealing devices should be installed at the bow and stern ends of the fixed stern tube. There are many forms of sealing devices, and the following are the main types and structures commonly used: packing sealing device, rubber ring sealing device and stern end sealing device.

Overview

If open lubrication is used for the stern tube bearings, a sealing device only needs to be installed at the bow end of the stern tube; If closed lubrication is used, sealing devices should be installed at the bow and stern ends of the fixed stern tube. There are many forms of sealing devices, and the following are the main types and structures commonly used: packing sealing device, rubber ring sealing device and stern end sealing device.

For more stern tube sealing device, kindly please click here.

For more marine shaft system components, kindly please click here.

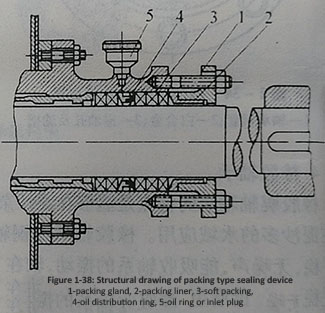

(1) Packing sealing device

Figure 1-38 is a structural diagram of a packing type sealing device. It mainly consists of packing gland liner, soft packing, oil distribution ring, oil cup or oil inlet plug. Sealing packing - usually 3-5 layers of butter rope or other appropriate packing rope. Press on the same packing gland. The lubricating oil enters the packing through the oil cup and oil distribution ring. When lubricating with water, the oil cup should be connected to a cooling water pipe and a water distribution ring should be used instead of an oil distribution ring.

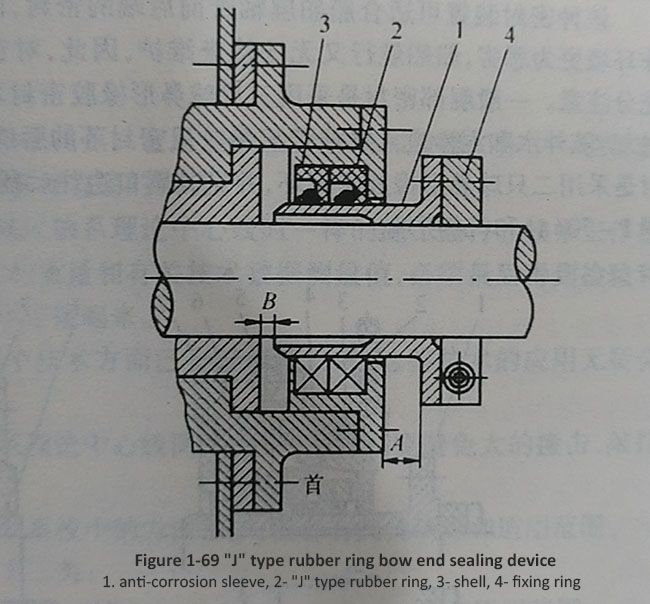

(2) Rubber ring sealing device

Figure 1-69 shows the J-shaped rubber ring type bow end sealing device. Adopting a J type oil resistant rubber ring with a spring, the outer surface of the ring is fixed on the outer shell. The sealing ring forms a lip shaped contact ring at the point of contact with the shaft. The sealing ring is tightly fitted into the sleeve and pressed onto the shaft using the lubricating oil pressure in the spring and shaft tube. This device is simple and has good sealing performance. The new type now mostly uses Simplex type rubber ring sealing devices.

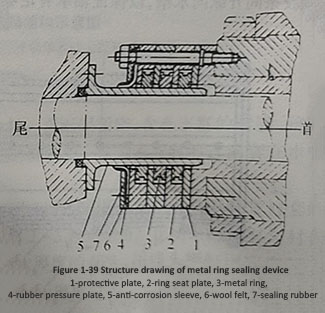

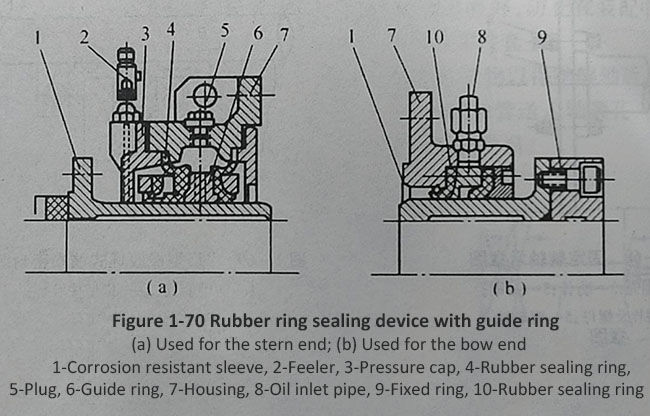

The rubber ring sealing device has good sealing performance, long service life, small friction loss, simple structure, and convenient repair and installation. Therefore, it is widely used in various types of stern tube sealing devices for ships. Sealing devices with guide rings are commonly used in large and medium-sized ships, as shown in Figure 1-70. Small and medium-sized ships commonly use skeleton or "J" non skeleton rubber ring sealing devices. In addition, the metal ring sealing device has good sealing performance and wear resistance, making it widely used, as shown in Figure 1-39.

(3) Stern end sealing device

Mainly composed of a bag shaped rubber ring, a corrosion-resistant sleeve shell for the guide ring, a pressure plate, and a pressure cover that are pressed onto the shell. The middle part is pressed and fixed onto the guide ring by the pressure plate, with the lips of the front rubber ring facing forward to prevent oil leakage, and the lips of the rear rubber ring facing backward to prevent water from seeping out of the string. Behind the bag shaped rubber ring, there is a small rubber ring (bowl shaped tight ring), with its lip facing back to prevent mud and sand from entering. These rubber rings are tightly fitted onto the anti-corrosion sleeve, which is attached to the stern shaft and fixed to the propeller at the rear end, allowing it to rotate together with the stern shaft. The inner ring of the guide ring is poured with white alloy, which is loose and fits with the outer circle of the anti-corrosion sleeve, and there are positioning concave shoulders on both ends to match, so that the stern shaft (rotating, axial movement sinking) can be tightly pressed against the anti-corrosion sleeve, thereby ensuring the sealing of the stern shaft tube.