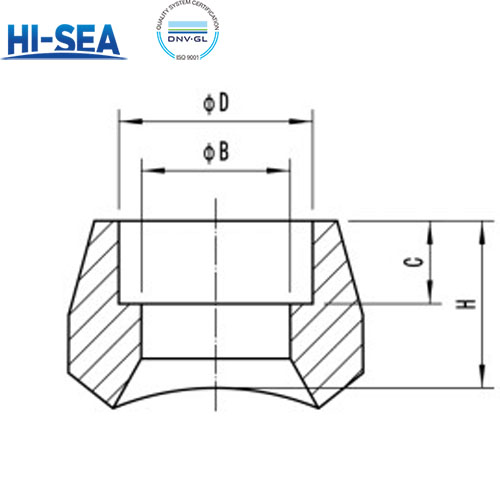

Socket Welded Branch Seat

Socket welded branch seat is a kind of connector used in pipeline system, mainly used for supporting and connecting various nodes in the pipeline system, it is welded by inserting the steel pipe into the socket hole, so as to realize the solid connection of the pipeline.

Overview

Main features

Connection form: Socket is mainly socket welding, this connection is reliable and suitable for high pressure, high temperature and other harsh environments.

Manufacturing standards: Follow international standards such as ANSI/ASME B16.11 to ensure quality and compatibility.

Material: The body is usually manufactured with high quality forgings, and the material is the same as the pipeline material, including carbon steel, alloy steel, stainless steel, etc. to adapt to different application scenarios.

Advantage

High temperature and pressure resistance

Wide applicability

Simple structure

Highly reliable

Good sealing

Strong anti-corrosion performance

Outside diameter | Outside diameter | EEMUA146 | |||||

θB | H | C | Theoretical | ||||

θD | θN | weight | |||||

nominal | actual | nominal | actual | mm | mm | mm | Kg/ piece |

inch | mm | inch | mm | ||||

0.5 | 16 | 0.75 to 1.5 | 25 to 44.5 | 12 | 25.4 | 10 | 0.1 |

0.5 | 16 | 2to 36 | 57 to 914 | 12 | 23.8 | 10 | 0.1 |

0.75 | 25 | 1 to 1.5 | 30 to 44.5 | 21 | 26.9 | 13 | 0.13 |

0.75 | 25 | 2to 36 | 57 to 914 | 21 | 25.4 | 13 | 0.13 |

1 | 30 | 1.25 to 1.5 | 38 to 44.5 | 25 | 33.3 | 13 | 0.22 |

1 | 30 | 2to 36 | 57 to 914 | 25 | 28.6 | 13 | 0.22 |

1.25 | 38 | 2to 36 | 57 to 914 | 33 | 33.3 | 13 | 0.35 |

1.25 | 38 | 2to36 | 57 to 914 | 33 | 33.3 | 13 | 0.35 |

1.5 | 44.5 | 2to36 | 57 to 914 | 39.5 | 30.2 | 13 | 0.5 |

1.5 | 44.5 | 2to 36 | 57to914 | 39.5 | 30.2 | 13 | 0.5 |

2 | 57 | 2.5 to 36 | 76.1 to 914 | 52 | 38.1 | 16 | 0.9 |

2 | 57 | 2.5 to 36 | 76.1 to 914 | 52 | 38.1 | 16 | 0.9 |