Introduction of Marine Manhole Cover

Marine manhole cover is a general term for the cover plate with sealing performance and its fixed accessories installed on the manhole. In ship design and construction, manhole cover is one of the key components of ship safety and functionality. Our Marine manhole cover product range is designed to provide superior quality and reliability to meet a wide range of ship types and needs.

Overview

Marine manhole cover is a general term for the cover plate with sealing performance and its fixed accessories installed on the manhole. According to the sealing plate setting condition: The raised manhole cover is provided with the raised sealing plate at the periphery of the manhole; a flat manhole cover with only one circle of flat seat plate at the periphery and fastened by stud bolts; the edge is provided with a sunken coaming plate, and the buried manhole cover is not protruding from the surface of the plate.

Marine manhole covers can be divided into oblong and circular according to their shape, of which oblong manhole covers are more widely used.

According to its tightness can be divided into oil-tight and watertight, the difference between the two lies in the material of the sealing gasket, oil tight should use oil-resistant rubber, watertight should use sea-resistant (light) water rubber.

Form of manhole cover

Manhole cover can be divided into protruding type and embedded type according to whether it is higher than the opening surface after installation.

Protruding manhole cover

According to CB/T19-2001 standard, the currently commonly used protruding manhole cover is divided into two types according to its structural form, that is, type A and type B.

Type A is an oblong protruding manhole cover. The coaming plate and seat ring are welded structure, 100mm above the opening plane. The commonly used specifications according to the through-hole size (L×B) are 450mrn×350mm, 600mm×400mm and 800mm×600mm. The thickness of the sealing plate (S1) is 4~14mm, and the thickness of the seat ring and cover plate (S) should be 2mm larger than the thickness of the sealing plate.

Type A manhole cover has a higher coaming plate, which prevents sewage or garbage from entering the cabin when the cover plate is opened. Therefore, it is usually used in engine rooms, boiler rooms and other places where water is easily accumulated. Here, Type A manhole covers can also be installed in places with curved surfaces, such as cylindrical crane barrel bases or spherical structures.

Type B manhole cover is an oblong and oval protruding manhole cover. The thickness of the seat ring is 20mm; the commonly used specifications and cover plate thickness are the same as the A-type manhole cover, and there is also an 800×400 oval manhole cover.

Type B manhole covers are widely used in manhole openings on decks, inner soles, platforms and bulkheads. When used for the bottom of the cargo hold, a steel frame should be installed around the manhole cover, and a steel cover plate or a wood cover plate should be added to make it gradually transition or flush the wood planks.

embedded manhole cover

According to the CB/T19-2001 standard, the commonly used embedded manhole covers can be divided into two types according to their structure, that is, type C and type D. Both of these manhole covers are oblong and oval, and their structure is shown in the figure. Type C manhole cover with a cover plate, the common specifications according to the through hole size (L×B) is 450×350mm, 600mm×400mm and 800mm×600mm, in addition, there is an 800mm×400mm oval manhole cover. The cover plate thickness (S) is 10~18mm. Type D manhole cover specifications are the same as type C, and its cover plate thickness (S) is 14~20mm.

Both type C and Type D manhole covers can be used in places such as the bottom of the cargo hold and deck passage where flat is required, as well as where cargo handling and personnel are easy to walk.

Material of manhole cover

The cover plate, coiling plate and seat ring of the manhole cover are usually made of hot-rolled carbon steel or the same material as the hull structure where the manhole cover is installed. The gaskets and handles are made of ordinary carbon steel, the sealing gaskets are made of flame retardant oil resistant or sea resistant (light) water rubber, the bolts or studs are made of stainless steel or carbon steel, and the nuts are made of carbon steel, stainless steel or brass. Bolts, studs, nuts and washers made of carbon steel should be galvanized.

Manhole cover selection and layout requirements

When selecting and arranging manhole covers, in addition to complying with the provisions of relevant conventions, rules and norms, strength, use and convenience should also be considered.

The strength of the manhole cover is mainly reflected in the thickness of the cover plate and the number of fastening bolts. In general, the thickness of the cover plate should not be less than the thickness of the hull structural steel plate (deck, platform, inner floor and bulkhead) at the installation site. Since the cover plate is more prone to corrosion than the hull structure steel plate around it, when the thickness of the hull structure steel plate at the manhole cover installation is less than 10mm, the thickness of the cover plate should be 1mm larger than the thickness of the hull structure steel plate there. If the deck or bulkhead of the manhole cover installation premises is determined by strength calculations, the thickness of the manhole cover shall be able to withstand the same water pressure conditions.

The manhole cover should be selected according to the density requirements of the cabin and the conditions of the installation space. Watertight manhole covers with sea (light) water resistant rubber as washers should be used for fresh water tanks, ballast water tanks and fore and aft peak tanks. Oil-tight manhole covers with oil-resistant rubber gaskets shall be used for fuel tanks, lubricating oil tanks and waste oil tanks. The A-type manhole cover with a coaming plate should be used on the inner bottom plate of the water accumulation and oil accumulation place such as the engine and furnace room and the top of the drinking water tank; when manhole covers must be set up in areas affecting personnel activities in passageways and living and working compartments, buried manhole covers should be selected. The manhole cover of the jet fuel tank must be made of brass to avoid sparks on impact. When the manhole cover may be in a humid environment for a long time, the bolts or studs should be made of stainless steel, and the nuts should be made of stainless steel or brass, or galvanized steel.

From the use of manhole cover, the size of the through hole is conducive to personnel access, but due to factors such as hull structure, mechanical equipment and pipeline layout, the size of manhole cover is limited to a certain extent. Usually in the plane position (deck, platform, inner bottom plate) to install the manhole size of 500mm×400mm is more appropriate, unless the layout is really difficult, as far as possible do not choose the manhole size of 450mm×350mm. A 600mm x 450mm manhole should be arranged on the bulkhead or other vertical parts, and the long axis should be arranged in the vertical direction. The lower edge of the through hole should be no less than 500mm high from the ground where the personnel are standing, so that the personnel can easily cross the manhole.

When the manhole cover is arranged on the deck, it should generally be close to the lower bulkhead, and the long axis of the manhole cover should be parallel to the bulkhead to facilitate the installation of a straight ladder under the manhole. In order to facilitate personnel access and ventilation, large liquid tanks and empty tanks, at least two manhole covers are set away from each other. The larger cabin in the double bottom shall be provided with manhole covers at both ends, and if necessary, an additional manhole cover shall be provided in the middle of its length. The manhole cover on the inner floor should be at least 800 to 1000mm away from the main bulkhead to avoid weakening the strength of the inner floor near the main bulkhead.

Whether the manhole cover is installed on the deck, platform, inner floor, or bulkhead, the hull frame should not be cut off as far as possible. If the arrangement is indeed difficult and the hull frame must be cut, it should be properly strengthened. In some important areas to ensure the strength of the hull structure, such as the deck side plate, the corner of the hatch and the part of the stress concentration area, the manhole cover shall not be set.

When manhole covers are set on the upper and lower decks or platforms at the same time, their positions should be staggered. Where there is a small hatch cover on the previous deck or platform, the manhole cover on the next deck or platform shall be set outside the projected range of the small hatch cover.

product drawing

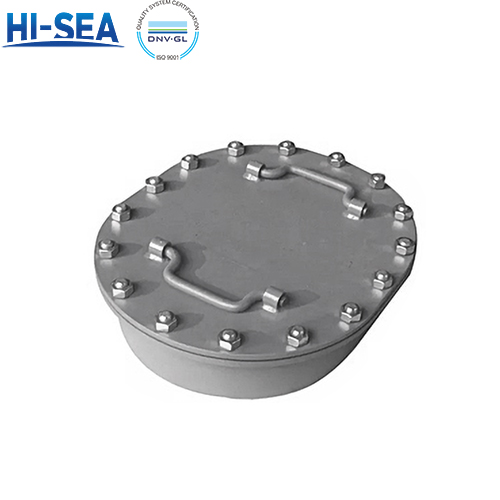

B type Low Profile Manhole cover