How Does A Marine Capstan Work?

To operate a capstan, the rope is pulled by hand and tied together, thereby creating friction between the rope itself and the winch drum. This in turn means that the pulling force of the engine/motor is applied to the rope, making it easier for objects to be lifted, moored, or anchored.

Overview

To operate a capstan, the rope is pulled by hand and tied together, thereby creating friction between the rope itself and the winch drum. This in turn means that the pulling force of the engine/motor is applied to the rope, making it easier for objects to be lifted, moored, or anchored.

Here's how it typically works:

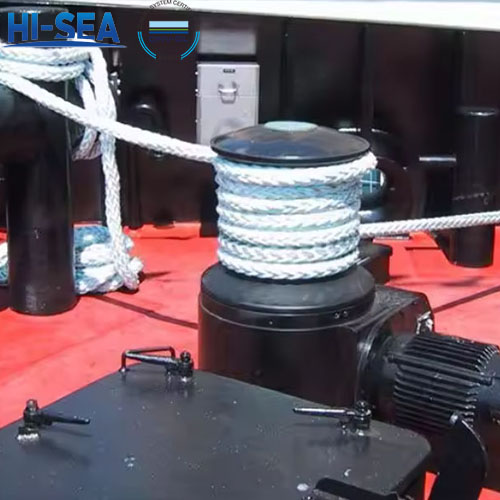

Basic Structure: A marine capstan consists of a vertical drum or barrel mounted on a vertical spindle or shaft. The drum has vertical ribs or grooves along its surface to provide grip for the rope or cable being wound around it.

Power Source: Traditionally, capstans were operated manually using bars inserted into holes or utilizing a hand-operated crank. However, modern ships often use powered capstans, which are driven by electric or hydraulic motors.

Operation: To operate the capstan, the rope or cable to be lifted or wound is attached to the drum. As the drum rotates, the rope or cable is wound around it. The rotational force applied to the drum creates tension in the rope, allowing it to lift or move the load attached to the other end.

Mechanical Advantage: The design of the capstan allows for a mechanical advantage, making it easier to lift heavy loads than it would be with pure manual force. The mechanical advantage is achieved by the diameter of the drum and the leverage provided by the capstan's design.

Overall, a marine capstan provides a reliable and efficient means of handling heavy loads and performing various tasks essential for the operation of a ship at sea.

For more marine capstan information, kindly please click here.