Application of Belt Brake in Marine Mooring Winches

The primary brake needs to render within a narrow, predictable load range to fulfil its role as part of the mooring safety system. Band brakes allow a relatively small input force to generate a high braking load and it is therefore possible for this type of brake to be manually applied.

Overview

The primary brake needs to render within a narrow, predictable load range to fulfil its role as part of the mooring safety system. Band brakes allow a relatively small input force to generate a high braking load and it is therefore possible for this type of brake to be manually applied.

Screw applied band brake

Screw applied and hydraulic assist band brakes are not recommended for new tonnage

over 16,000 DWT.

The simple band brake with screw application requires regular maintenance, regular load testing and special care in operation to achieve predictable brake load settings, even when torque wrenches are used.

The main problem with the screw applied band brake is their manual operation. Once

moored, if the line load increases the brake band will stretch. The operator may be tempted to keep re-tightening the brake wheel to the original wheel torque setting. This re-tightening might lead to the mooring line parting before the brake slips. The problem can be mitigated by using spring applied brakes.

A variation on the screw applied brake uses a hydraulic cylinder to set the brake. A pressure gauge connected to the cylinder allows the brake to be applied to the brake load setting. Once the brake is applied with the hydraulic assist, the load is transferred to the mechanical linkage by tightening the handwheel until the pressure in the assist cylinder starts to drop. Although this feature eliminates the need for a torque wrench, the brake has the same drawbacks as the screw applied brake.

Spring applied brakes

A manually operated spring applied brake is shown in figure 1. When tightening the brake screw, the spring is compressed and the compression is proportional to the holding load of the brake. When the brake is tested and adjusted to the correct rendering force, an indicator is adjusted so that the brake can be reset repeatedly to its correct value. This type of spring applied brake setting indicator compensates fully for any wear of the brake lining and elongation in the brake mechanism.

Figure 1: Spring applied broke with manual setting

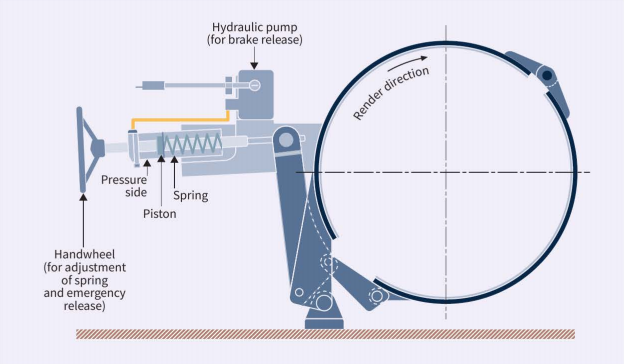

A spring applied band brake with hydraulic release is shown in figure 2. In the case shown, the brake is released by a hydraulic hand pump. To apply the brake, a valve is opened to release the hydraulic pressure. Winches with hydraulic drives can use the main hydraulic pressure to release the brake.

The handwheel is not used for routine operation. It is used to adjust the spring compression during calibration and to release the brake in case of a hydraulic malfunction. The handwheel should be secured with a seal after each calibration to prevent tampering. Alternatively, the brake screw can be equipped with a brake setting indicator to provide an easy visual check of the correct adjustment of the brake setting.

Figure 2: Spring applied brake with hydraulic release

For more marine winch information, kindly please click here.