The difference between marine hydraulic towing winch and marine hydraulic mooring winch

In marine hydraulic equipment, although hydraulic towing winch and hydraulic mooring winch belong to the same type of hydraulic driven, there are significant differences their distinct operational contexts and functional purposes. The core distinctions lie in the presence of the emergency release function and the fundamental divergence in load conditions. Key differences are outlined below:

Overview

In marine hydraulic equipment, although hydraulic towing winch and hydraulic mooring winch belong to the same type of hydraulic driven, there are significant differences their distinct operational contexts and functional purposes. The core distinctions lie in the presence of the emergency release function and the fundamental divergence in load conditions. Key differences are outlined below:

1. Emergency Release function

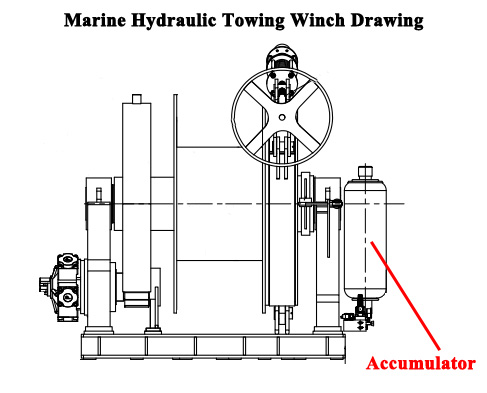

Hydraulic towing winch: Mandatory configuration of an Emergency Release System, used to proactively cut off wire ropes in emergency situations, ensuring the safety of the vessel (abandoning cables to protect the ship). Emergency release is mainly achieved through hydraulic brake system and accumulator.

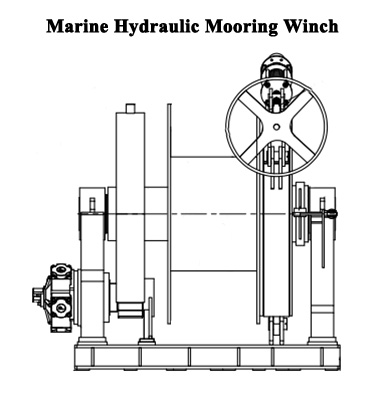

Hydraulic mooring winch: No emergency release function, relying on passive locking devices to maintain the tethered state.

2. Main load conditions

Winch Type | Key operating conditions | Load requirements | Force characteristics |

Hydraulic towing winch | Braking load / Holding load / Support load | The max drum/working load is 50% of the breaking load of the steel wire rope, and braking load ≥ 110% breaking load of the wire rope. | Need to continuously withstand the weight and tension of the towing object. Continuously withstand dynamic loads (such as wind waves, water flow impacts). |

Hydraulic mooring winch | Working load | The drum/working load is ≤ 33% of the designed rope breaking load, and the supported load is ≥ 80% of the breaking load | Emphasis is placed on completing the rope retraction and tension control during the ship mooring process. Mainly dealing with static mooring forces (such as tidal gentle loads) |

3. Applications & cable type

Winch type | Cable type | Key applications | Applicable scenarios |

Hydraulic towing winch | Only applicable to steel wire ropes | Connect the tugboat to the towed object, bear the towing load, and realize the retrieval and storage of ropes and steel wire ropes. | Tugboat, rescue boat, etc., used for towing or rescuing |

Hydraulic mooring winch | Steel wire rope, synthetic fiber rope, etc., such as polyimide or polyamide rope | Mooring operations for ships to assist in securing their position during terminal | Calm waters such as ports and docks or teminal |

4. Design Standards

Winch Type | Applicable Standards |

Marine Towing Winch | - GB/T 11869-2007 (Towing Winches for Deep Sea Use) |

- ISO 7365:2012 (Shipbuilding and Marine Structure — Deck Machinery — Towing Winches for Deep Sea Use) | |

Marine Mooring Winch | - GB/T 4446-1995 (Mooring Winches) - GB/T 4446-2025(New Revision) |

- ISO 3730:2012 (Shipbuilding and Marine Structure — Mooring Winches) | |

*Note: GB/T 4446-1995 remains valid until superseded by the 2025 revision.* | |