Technical Design Requirements for Marine Low-Pressure Air Receivers

Designing marine low-pressure air receivers involves several technical requirements and considerations to ensure safety, efficiency, and compliance with relevant standards. The design, manufacturing, and acceptance requirements for marine low-pressure air receivers in harsh marine environments are centered on ensuring the safe and reliable operation of the equipment throughout its entire service life. All technical requirements are structured around three core pillars: "Environmental Adaptability," "Inherent Safety Design," and "Standardized Manufacturing Processes."

Overview

1. Marine Environmental Conditions:

The marine air receiver shall be capable of operating normally under the following conditions: a static heeling of 15° and rolling of 22.5°, combined with a static trim of 5° and pitching of 7.5°. (For vessels with a length exceeding 100 meters, the trim angle may be taken as 500/L, where L is the overall length of the vessel in meters.)

2. Design:

2.1 The air receiver shall include the receiver body, an inlet valve, an outlet valve, a pressure gauge valve, a drain valve, a safety valve or a fusible plug, and valves for operating remote‑control valves.

2.2 The design pressure of the air receiver shall be 1.1 times the working pressure.

2.3 For an air receiver fitted with a safety valve, its design pressure shall not be lower than the set pressure of the safety valve.

2.4 The opening pressure of the safety valve shall be higher than the working pressure of the air receiver but lower than the design pressure; the reseating pressure shall not be less than 0.85 times the working pressure.

2.5 The body of the air receiver shall withstand a hydraulic test pressure equal to 1.5 times the design pressure without any leakage or sweating, and no abnormal deformation is permitted.

2.6 A complete set of air‑receiver units shall withstand a pneumatic test at the working pressure without leakage.

2.7 Where a safety valve is fitted on the air inlet pipe or on the compressor, and the charging process prevents the pressure inside the receiver from exceeding the design pressure, a safety valve may be omitted on the air receiver itself. In such a case, a fusible plug shall be installed. The fusible plug shall have a melting point of approximately 100 °C (typically 95±5 °C), and its dimensions shall ensure effective air release in the event of a fire. Air receivers intended for operating remote‑control valves shall still be equipped with a safety valve.

2.8 The design drawings of the air receiver shall indicate the calculated thickness or the specified minimum wall thickness (excluding corrosion allowance).

2.9 When determining the additional wall thickness allowance in the design, consideration shall be given not only to corrosion, erosion, and wear caused by the medium, but also to an adequate corrosion allowance over the intended service life, so as to meet the requirements for safe operation of the air receiver.

2.10 For air receivers with a shell diameter less than 700 mm, an inspection opening shall be provided; for those with a shell diameter equal to or greater than 700 mm, a manhole shall be provided. The diameter of a circular inspection opening shall not be less than 75 mm; the dimensions of an elliptical inspection opening shall not be less than 75 mm × 50 mm. The dimensions of an elliptical manhole shall not be less than 400 mm × 300 mm, and the minor axis of the manhole shall be arranged, as far as practicable, along the longitudinal direction of the shell.

2.11 Both manhole covers and inspection opening covers that are closed from the inside shall have a boss. The clearance around the boss and the manhole or inspection opening shall not exceed 2 mm. The sealing material shall be a copper gasket or oil-resistant rubber.

2.12 The drain device shall be capable of draining residual water from the lowest point inside the air receiver.

2.13 The longitudinal weld joints of the air receiver shell, the circumferential joints connecting shell sections to each other and to the heads, as well as the spliced joints of heads, shall be of the full penetration butt joint type. When back welding is genuinely impossible, it is permissible to install a backing strip for welding, provided the strip material has the same composition as the shell plate.

2.14 Reinforcing fittings on the air receiver, as well as peripherally welded backing strips serving a strengthening purpose, shall have at least one leakage indication hole with a diameter not less than M6.

3. Manufacturing

3.1 Heads and shells shall be formed by cold or hot working but shall not be hammer-formed. When heads are formed by hot pressing, burning (overheating) shall be avoided.

3.2 Weld preparation edges (welding grooves) for heads and shells shall be machined or cut. The type of weld groove and the fit-up gap shall comply with the provisions of GB 985 or GB 986.

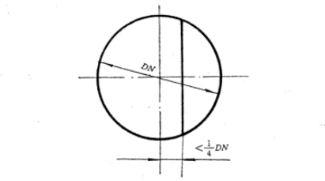

3.3 When a head is made by butt-welding two steel plates, the distance from the butt weld to the head's centerline shall be less than one-quarter of the air receiver's internal diameter, as shown in the figure 1.

Figure 1:

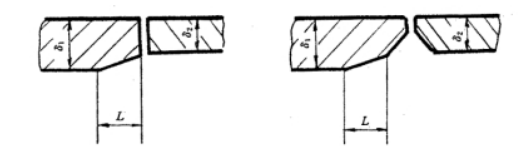

3.4 When butt-welding the head to the shell, if the thicknesses of the two plates are unequal, the thicker plate shall be tapered so that its edge thickness matches that of the thinner plate. The length of the taper shall be equal to or greater than four times the difference in thickness, as shown in the figure 2 below.

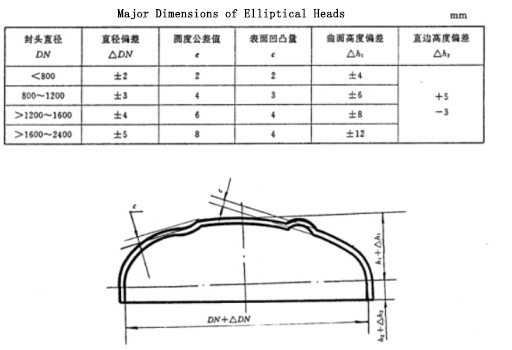

3.5 The tolerances for the major dimensions of elliptical heads shall comply with the specifications, as shown in the figure 3 below.

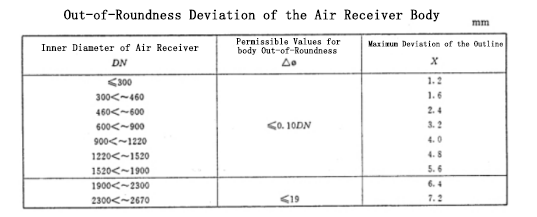

3.6 During the rolling of the cylindrical shell, defects such as edge misalignment, excessive curvature, hourglass shape, or bulging shall be prevented. The shell shall be configured to match the diameter of the finished head. The out-of-roundness of the shell shall comply with the specifications in the following table.

3.7 The deviation in the length of the cylindrical shell shall not exceed 3 mm. The straightness shall not exceed 1.5 mm per meter of length, but shall not exceed 5 mm over the entire length of the air receiver.