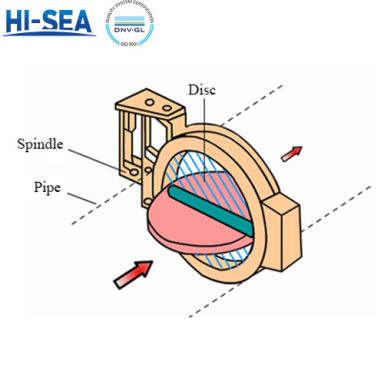

Marine Butterfly Valve Disc and Seal Material Recommendation

In offshore platforms, material corrosion poses significant risks and incurs high costs. During the operation of marine butterfly valves, the flow and erosion of the medium further corrode the valve disc and sealing surfaces. Therefore, material selection is critical to the service life of butterfly valves.

Overview

Select the corresponding valve disc based on the medium's acidity/alkalinity, temperature, and other characteristics. Marine butterfly valves primarily use aluminum bronze or stainless steel for their valve discs.

Aluminum bronze discs offer heat resistance and corrosion resistance; suitable for freshwater, seawater, oils, etc.

Stainless steel discs provide high-temperature resistance and corrosion resistance; suitable for freshwater, weak acids, natural gas, steam, etc

Al Bronze Disc | Stainless Steel Disc |

|

|

Metal seals are mainly suitable for high-temperature and high-pressure environments; under normal operating conditions, soft-seal butterfly valves ensure both fluid flow and sealing integrity.

The following are four commonly used soft seals:

Sealing Material | NBR | EPDM | FKM | PTFE |

Operating Temperature | -40℃-93℃ | -50℃-135℃ | -23℃-200℃ | -200℃-180℃ |

Applicable Media | Freshwater, seawater, weakly alkaline , natural gas, oils | Freshwater, seawater, strong alkali, weak acid, air | Freshwater, seawater, natural gas, steam, oils | Freshwater, seawater, strong alkalis, strong acids, alcohols, steam, oils |

Key Features | Oil-resistant | Aging-resistant | High-temperature resistant | Corrosion-resistant, high-temperature resistant |

Image Reference |  |  |  |  |

The fit between the valve disc and seal directly impacts fluid sealing performance. When selecting stainless steel or aluminum bronze valve discs, choose based on the medium's properties, temperature, and pressure. Regarding sealing: Metal seals withstand high temperatures and pressures, making them suitable for more demanding operating conditions. Elastic seals have greater temperature limitations but offer more stable sealing performance.