Difference Between Industrial Chain and Anchor Chain

Although industrial chains and anchor chains are both called "chains", the difference is actually bigger than expected.

First of all, the application scenarios are completely different: one is mechanical transmission on land, and the other is mooring equipment at sea.

This directly leads to the differentiation of design concept-industrial chain pursues precision fit and fatigue life, while anchor chain has to carry ocean corrosion and impact load hard.

Overview

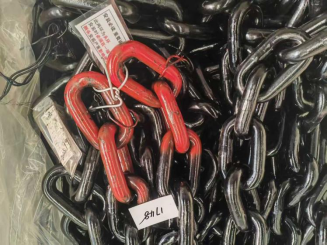

Grade 100, 30*108mm Chains for mining industry

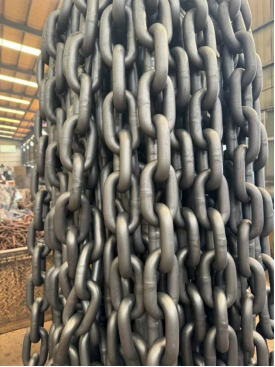

Grade 3, Dia. 78mm Anchor Chain

The following are the main differences between the two:

Characteristic | Industrial Chain | Anchor Chain |

Main Application | Power transmission (transmission chain), material transportation (conveyor chain), traction/lifting (traction chain). Used to transfer power or move objects inside or between mechanical equipment. | Mooring ship. Connecting the anchor with the hull, or mooring the ship on the wharf or buoy, mainly bears static and dynamic tension. Ships (merchant ships, warships, yachts), offshore platforms, buoy mooring and permanent mooring facilities at sea. |

Key Functional Requirements

| 1. Transfer power 2. Continuous movement 3. Wear resistance | 1. Bear huge static load and dynamic load 2. Corrosion resistance: long-term immersion in seawater. 3. Impact toughness: withstand the impact of anchoring, anchoring and wind and waves. 4. Reliability: The consequences of failure are extremely serious (ship drifting and collision). |

Structure | 1. Multi-component assembly: usually composed of inner chain plate, outer chain plate, pin shaft, sleeve and roller. 2. Flexible rotation is achieved through precise fit. | Integral forging or casting welding: the basic unit is the link. Common types as follow: 1. Stud link: there is a transverse brace in the middle of the link to increase strength and prevent deformation. 2. Stud-less link: a simple oval ring. |

Material | 1. Alloy steel: medium carbon steel and medium carbon alloy steel (such as 40Cr, 40Mn, etc.). 2. Heat treatment: surface hardening (carburizing and quenching) to improve wear resistance and strength. 3. Surface treatment: zinc plating, nickel plating, blackening or oiling for rust prevention. | 1. High strength special alloy steel 2. Heat treatment: overall tempering treatment (quenching+high temperature tempering) to obtain the best comprehensive mechanical properties. |

Manufacturing Process | 1. Precision stamping, 2. Cold heading/turning, 3. heat treatment 4. Precision assembly | 1. Forging/casting (blank), |

Strength Standard | Tensile strength and fatigue strength are the core indicators. According to ISO, ANSI, DIN, JIS and other standards (such as A/B series of ISO 606, 25/35/40 of ANSI, etc.). | Breaking strength is the core index. According to the classification society specifications (such as K1, K2, K3, K4, etc., K4 has the highest strength). Must pass the classification society certification (such as DNV GL, ABS, LR, CCS, etc.). |

30×108 Carburized Chain

Stud Link Anchor Chain

Key Summary:

1. Different missions: the core of industrial chain is to transmit power or movement; The core of the anchor chain is to bear and fix the huge tensile force.

2. Different environment: industrial chain is mainly in land or controlled industrial environment; Anchor chain in harsh marine environment (seawater corrosion, sediment abrasion, biological adhesion).

3. The nature of the structure is different: industrial chain is a multi-part precision assembly mechanism; Anchor chain is a thick, forged/welded steel structure.

4. Core performance: industrial chain emphasizes fatigue strength, wear resistance and transmission efficiency; Anchor chain emphasizes breaking strength, corrosion resistance and toughness.

5. Important: Mixing is absolutely forbidden! It is extremely dangerous to use industrial chain as anchor chain, because industrial chain can not withstand the corrosion of marine environment and huge impact load, and it is easy to break and lead to serious accidents.

.png)