Composition, workflow, and material requirements of the marine air receivers

Marine air receivers are critical equipment in a ship's propulsion and auxiliary systems. Their primary purpose is to supply compressed air for engine starting, control systems, safety functions, and general service applications. As essential equipment on board vessels, the components and materials of marine air receivers are subject to extremely stringent design requirements to ensure their safe and reliable operation in harsh marine environments.

Overview

Marine air receivers are critical equipment in a ship's propulsion and auxiliary systems. Their primary purpose is to supply compressed air for engine starting, control systems, safety functions, and general service applications. As essential equipment on board vessels, the components and materials of marine air receivers are subject to extremely stringent design requirements to ensure their safe and reliable operation in harsh marine environments.

I. Component Composition

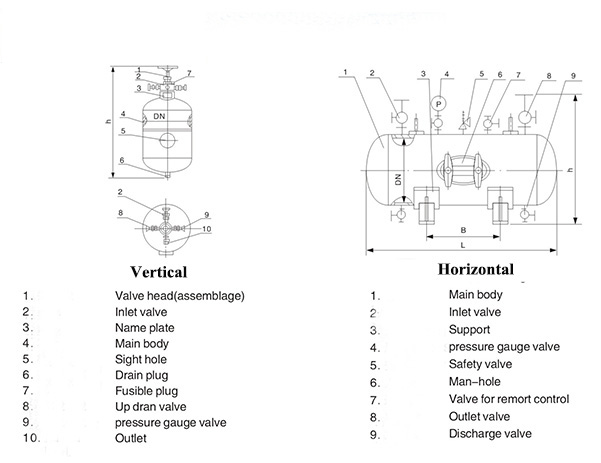

Part Name | Function and purpose |

Main body | The main body section for storing compressed air. |

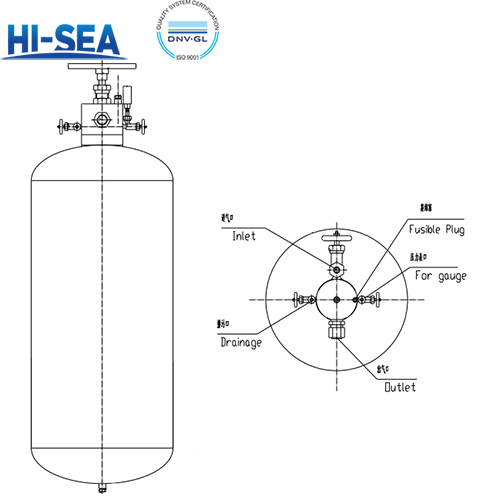

Inlet & Outlet Valve | Used to control the flow of air into and out of the cylinder. This valve can be manually closed to isolate the air receiver during maintenance or emergencies. |

Pressure Gauge Valve | Provides a visual indication of the current air pressure inside the receiver, allowing crew to monitor the air reserve level conveniently. |

Safety Valve | 1. A safety device to prevent explosion caused by excessive pressure inside the cylinder. 2. If the internal pressure exceeds the safe limit due to temperature rise or other abnormal conditions, the safety valve automatically opens to release pressure, preventing an explosion from overpressure. |

Drain/Discharge Valve | 1. Used for periodically discharging oil and water condensed from the compressed air. This is crucial maintenance to prevent internal corrosion of the shell and failures in downstream pipelines/equipment. 2. Typically located at the lowest point of the air receiver. |

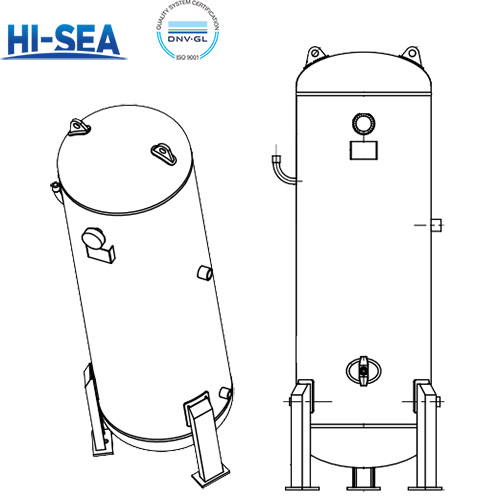

Mounting Base/pedestal | 1. A support structure welded or fixed to the shell. 2. Securely fastens the air receiver to the ship's foundation or bulkhead, preventing movement due to the ship's rolling. |

Man-hole /sight hole (if applicable) | An opening to facilitate inspection, installation, and maintenance. |

Fusible Plug (if applicable) | 1. A plug embedded with a low-melting-point alloy. While not mandatory for all air receivers, it is installed on some according to specific rules or applications. 2. Acts as a fire safety device. If a surrounding fire causes the temperature to rise sharply to the alloy's melting point (typically 70°C - 100°C), the plug melts, releasing the high-pressure air in a controlled manner to the atmosphere, preventing the shell from exploding in the fire. |

A typical marine air receiver system is an integrated unit formed by these four major categories of components: Main body, Mounting Base, Control Valves (Inlet/Outlet Valve, Drain Valve), and Safety/Monitoring Devices (Safety Valve/Pressure Gauge Valve). The core design principles are safety, reliability, and ease of maintenance, ensuring that the ship receives a stable and reliable supply of compressed air under various sea conditions. | |

II. Basic Operational Workflow

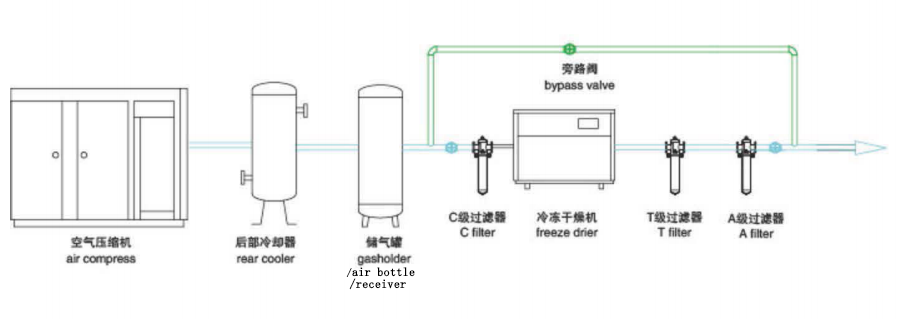

The air compressor charges the receiver via the inlet valve → The pressure gauge indicates the rising pressure → When air is needed, the main outlet valve is opened → Compressed air is supplied through the pipeline system to consumers like the main engine starting system, whistle, and control systems → Condensate is periodically drained via the drain valve. Throughout this process, the safety valve and fusible plug remain on standby, ensuring operational safety.

III. Compressed Air System Setting Configuration Reference Drawing

Ⅵ. Material Selection

The selection of materials for marine air receivers must consider factors such as strength, corrosion resistance, weldability, and cost-effectiveness. Common materials include:

1. Carbon Steel: Offers good strength and weldability, but its corrosion resistance is relatively poor, requiring anti-corrosion treatment.

2. Stainless Steel: Provides excellent corrosion resistance, but comes at a higher cost. It is suitable for applications where high corrosion resistance is required.

3. Alloy Steel: Combines the advantages of strength and corrosion resistance, but is also relatively expensive.

Specifically, the receiver shell (body) is often made from high-strength steel grades such as Q345R, while valves and other attachments may use materials like cast steel or stainless steel.

All major pressure support component materials must meet relevant standard requirements. If there are class certificate requirements, a marine product certificate issued by the corresponding classification society must be held.

Part Name | Material code | Standard/Rules |

Body & head | Q345R or CB/T 493-2998, CCS approved equivalent marine steel plates,steel pipes and welding condsumables | GB 713 or CCS Rules for Materials and Welding. |

connecting pipe, flange | 20# or 304 stainless steel | GB/T 8163 or GB/T 14976 |

Base/Pedestal | Q235-B | GB/T 700 |