What is Marine Gate Valve?

Overview

Working Principle

Gate valves are available in various materials, sizes, and designs to suit different applications and environmental conditions. Common materials include brass, bronze, cast iron, stainless steel, and others, depending on the specific requirements of the system in which they are used.

Gate valves is that they offer good sealing properties when fully closed, preventing leakage. They are often used in on-off applications, where the valve is either fully open or fully closed with little need for flow control.

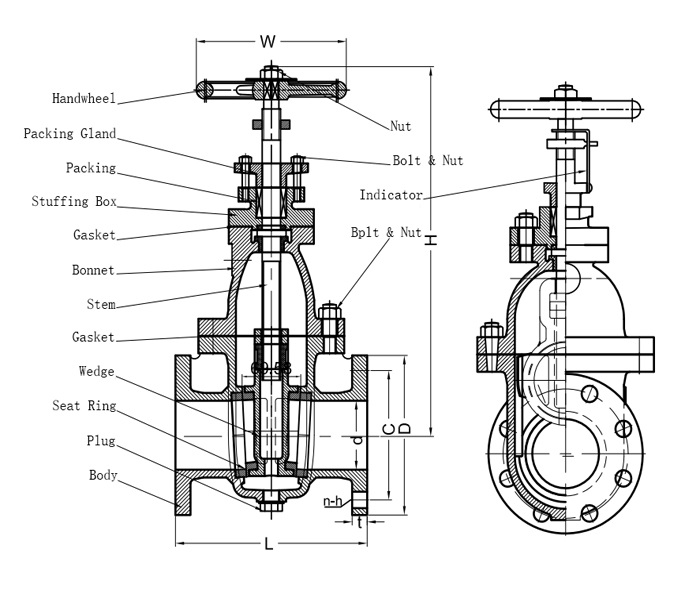

Gate valve typically consists of several main parts:

1. Body: The main outer casing of the valve that houses the other components.

2. Gate: A flat or wedge-shaped barrier that can be raised or lowered within the valve to control the flow of fluid.

3. Stem: The rod connected to the gate that is used to raise and lower it. The stem extends outside the valve for manual operation or can be connected to an actuator for automated control.

4. Bonnet: The cover that encases the stem and helps seal the valve.

5. Packing: Material used to create a seal around the stem to prevent leakage.

6. Seat: The surface against which the gate closes to stop the flow of fluid.

7. Handwheel or Actuator: For manual valves, a handwheel is used to turn the stem and control the gate's position. In automated valves, an actuator is attached to the stem for remote or automatic operation.

Drawing:

Image of the Gate Valve

MAIN DIMENSIONS | ||||||||

SIZE | d | L | D | C | t | H | N-h | W |

50A | 50 | 200 | 155 | 120 | 20 | 300 | 4*19 | 140 |

65A | 65 | 220 | 175 | 140 | 22 | 350 | 4*19 | 160 |

80A | 80 | 230 | 185 | 150 | 22 | 400 | 8*19 | 180 |

100A | 100 | 250 | 210 | 175 | 24 | 450 | 8*19 | 200 |

125A | 125 | 270 | 250 | 210 | 24 | 520 | 8*23 | 224 |

150A | 150 | 290 | 280 | 240 | 26 | 580 | 8*23 | 250 |

200A | 200 | 320 | 330 | 290 | 26 | 700 | 12*23 | 315 |

250A | 250 | 380 | 400 | 355 | 30 | 840 | 12*25 | 400 |