What is a stern tube bearing?

A bearing installed inside the stern shaft tube to support the stern shaft or propeller shaft. There are two types of stern tube bearing: sliding bearings and rolling bearings. One of the critical components in the propulsion system of a ship is the stern tube bearing. Located at the stern of the vessel, the stern tube bearing serves a pivotal function by facilitating the smooth rotation of the propeller shaft, which in turn drives the ship forward through the water.

Overview

Definition

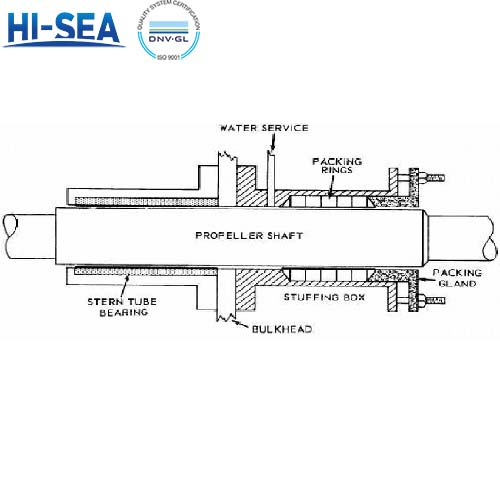

A bearing installed inside the stern shaft tube to support the stern shaft or propeller shaft. There are two types of stern tube bearing: sliding bearings and rolling bearings. Rolling bearings are rarely used due to inconvenient disassembly and assembly. Sliding bearings can be divided into white alloy bearings, iron pear wood bearings, rubber bearings, and plastic bearings according to their materials. Plastic bearings also include fabric laminates, gluewood laminates, and nylon. For iron pear wood and plastic tail shaft tube bearings, outboard water is often used for lubrication and cooling. There are two types of lubrication using outboard water: natural lubrication and forced lubrication. For white alloy tail bearings, forced oil lubrication is commonly used. The tail shaft tube bearings are generally set at the front and rear ends of the tail shaft tube. Due to the need for the rear end bearings to withstand the load of the thruster, they are relatively long. Under the condition of ensuring sealing, forced lubrication can prolong the service life of the tail shaft tube bearings, so good oil seal devices should be installed at the front and rear ends of the tail shaft tube.

For more marine shaft system components, kindly please click here.

For more marine shaft system components, kindly please click here.

Inspection of stern tube bearings

Check the sealing performance of the tail shaft tube and the temperature of the lubricating oil.

The tail shaft tube bearings made of materials such as iron pear wood, laminated board, rubber or laminated rubber are lubricated with seawater. Under normal circumstances, its temperature does not change much, but if the sealing packing is pressed too tightly or lacks lubricating grease, it may cause overheating of the tail shaft and packing gland. In addition, excessive wear and tear will increase the amount of seawater leaked in. Therefore, marine engineers should mainly measure and inspect the bearing clearance regularly. If it exceeds the allowable limit value, it should be repaired or updated in the factory. At present, most tailpipe bearings are made of white alloy bearings or rolling bearings, and lubricated with lubricating oil and grease. For this type of bearing, it is mainly necessary to check for seawater leakage or lubricating oil leakage, in order to determine whether the sealing device of the tail shaft tube is damaged; At the same time, the temperature of the lubricating oil should also be checked. If the oil temperature is too high, the cause should be promptly identified and measures taken to eliminate it.

Stern Tube Bearing Components

Bearing Housing: The bearing housing is a metal casing that holds the stern tube bearings in place. It provides protection and support for the bearings and helps maintain alignment of the propeller shaft. It usually made from durable materials such as white metal or composite materials.

Bushing or Sleeve: The sleeve or bushing is fitted inside the bearing and makes direct contact with the propeller shaft.

Seal System: Prevents the leakage of lubricants and prevents seawater from entering the bearing assembly, ensuring the longevity of the bearings and other components.

Lubrication System: The lubrication system is responsible for providing a continuous supply of oil, water or grease to ensure the bearing is sufficiently lubricated during operation, which helps reduce friction and heat generation, ensuring smooth operation of the propeller shaft.

Support Structures: These include bolts and brackets that secure the bearing in place, ensuring it remains stable and properly positioned during ship operation.