What is a shaft coupling?

Couplings are also referred to as couplings, flanges, corbelins, flanges, and so on in applications.

The connecting component that connects two shafts together in a shaft system is called a coupling.

There are many structural forms of couplings, and commonly used in ship shaft systems include integral forged couplings, removable couplings, hydraulic couplings, elastic couplings, etc.

Overview

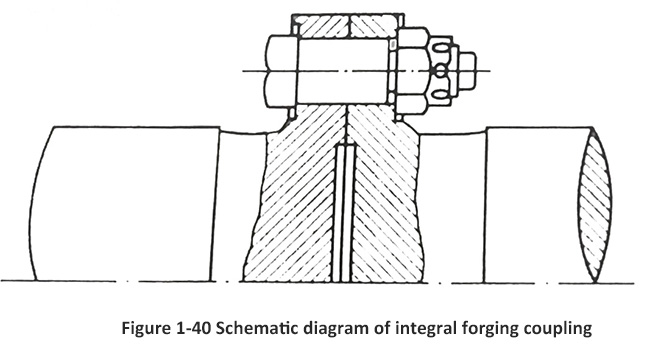

(1) Whole forged coupling

The coupling and shaft are forged as a whole. The whole forging method has a simple structure, reliable operation, light weight, and economical manufacturing, making it a common coupling in ship shaft systems. Figure I-40 shows a typical structure of a forged coupling, connected by cylindrical bolts.

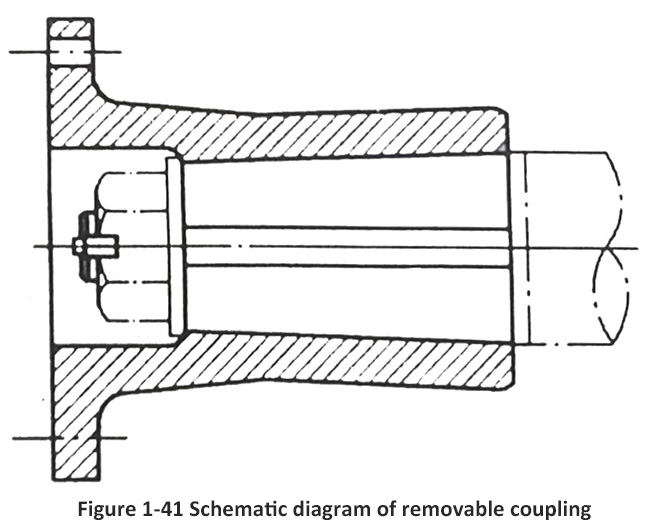

(2) Removable coupling

When it is required to load people from outside the ship to inside the ship, or on shafts using rolling bearings, integral forged flanges cannot be used, but detachable couplings must be installed. The typical structure of a detachable coupling is shown in Figure 1-41. The flange diameter of the detachable coupling is larger than that of the forged flange, and the flange of the corresponding shaft connected to it must also be correspondingly increased.

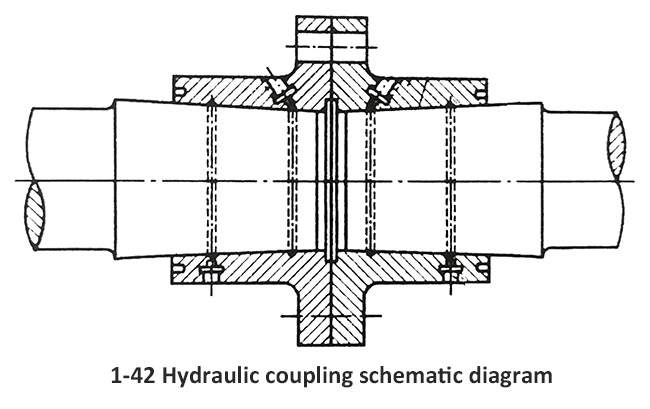

(3) Hydraulic coupling

Hydraulic coupling is also a structural form of detachable coupling. The assembly principle is to insert high-pressure oil pressure between the coupling (or intermediate sleeve) and the shaft, causing the inner hole of the coupling to expand and the shaft to be compressed. At this time, axial thrust is applied, and when the predetermined position is reached, the oil pressure is released to tighten the coupling on the shaft. Figure 1-42 shows the structure of a hydraulic coupling. Its advantages are large torque transmission and simple processing

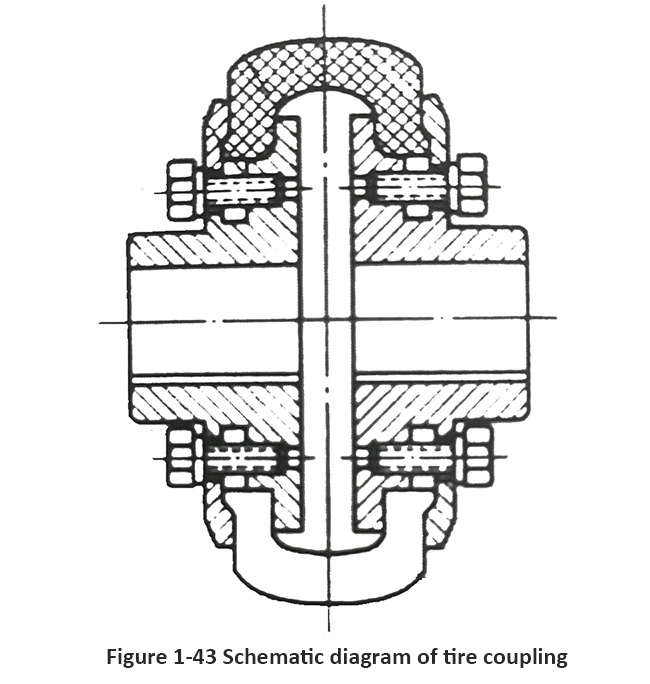

(4) Elastic coupling

Elastic couplings can be divided into elastic cylindrical pin couplings, tire couplings, and cylindrical rubber couplings. The main advantage of this type of coupling is its ability to absorb vibration and buffer, with lower requirements for shaft alignment than rigid couplings, and easy installation. The elastic cylindrical pin coupling is mainly connected by the plug pin of the rubber lining ring to connect the two halves of the coupling. This type of coupling has already been applied in ships. The tire coupling shown in Figure 1-43 can cushion the impact of high-speed rotation.

In addition, a relatively new type of hydraulic transmission coupling has been widely used in various types of ships.

For more marine shaft system components, kindly please click here.