The material of marine propellers

Marine propeller is the most important equipment for ships, and suitable materials are very important.

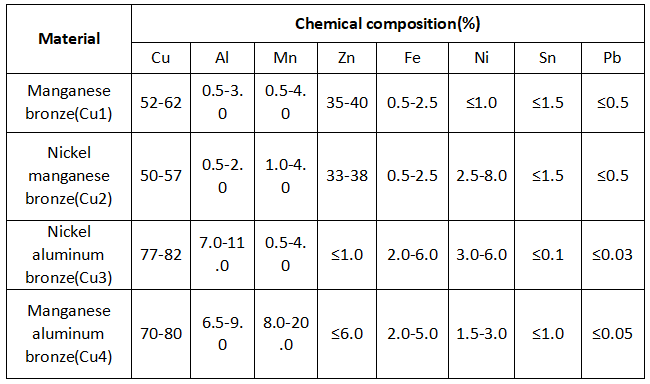

The main materials of marine propellers are: Manganese bronze(Cu1), Nickel manganese bronze(Cu2), Nickel aluminum bronze(Cu3), Manganese aluminum bronze(Cu4), Stainless Steel, Cast Iron , etc.

Choosing the appropriate propeller material can significantly improve the performance and operational efficiency of ships, while reducing maintenance costs and extending their service life.

Overview

Marine propeller is the most important equipment for ships, and suitable materials are very important. The following are common propeller material compositions.

Main Characteristics

1. Manganese Bronze

Ingredients: Mainly composed of copper, manganese, zinc, and aluminum.

characteristic:

High strength and wear resistance: suitable for withstanding high loads and long-term operation.

Good corrosion resistance: Excellent performance in seawater.

Good processability: easy to cast and process.

2. Nickel Aluminum Bronze

Ingredients: Mainly composed of copper, nickel, aluminum, and iron.

characteristic:

Extremely high corrosion resistance: especially suitable for seawater environments.

High strength and hardness: able to withstand high stress and wear.

Good fatigue resistance: suitable for long-term continuous operation.

3. Nickel manganese bronze

High strength, good hardness, good wear resistance, good elasticity, no spark, corrosion resistance, non-magnetic, excellent cold working performance, excellent electroplating and welding performance.

4. Cast Iron

Ingredients: Mainly composed of iron, carbon, and silicon.

characteristic:

Low cost: The price is relatively low.

Suitable for inland vessels: usually used for inland vessels with low requirements for corrosion resistance.

5. Stainless Steel

Ingredients: Mainly composed of iron, chromium, nickel, and molybdenum.

characteristic:

Extremely high corrosion resistance: suitable for marine and freshwater environments.

High strength and wear resistance: able to withstand high loads and wear.

High manufacturing cost: suitable for high-performance and specialized ships.

Considerations for selecting materials

Working environment: such as the corrosiveness and temperature of seawater.

Ship type: Different ships have different requirements for propeller performance, such as cargo ships, yachts, and submarines.

Load requirements: The thrust and torque that the propeller needs to withstand.

Manufacturing cost: economy and processability.

Repair and maintenance: durability and ease of maintenance of materials.

For more marine propeller information, kindly please click here.