Technical Requirements for Marine Manhole Covers

The manhole cover is an important part of the ship, providing the crew with access to the cabin for operation, maintenance and overhaul. In addition, the manhole cover has good sealing performance in the closed state, which can effectively prevent water, liquid or other substances from entering the cabin and ensure the safety of the ship's equipment and cargo. It is important that the design of the manhole cover combined with the hull structure can play a certain strengthening role to enhance the structural strength and stability of the hull. Therefore, this article will introduce the technical requirements of Marine manhole cover in the design, manufacturing and installation process according to CB/T 19-2001 standard, so that you can choose Marine manhole cover more clearly.

Overview

CB/T 19-2001 is the technical requirements for Marine manhole covers stipulated in China Shipping standards, and its main purpose is to ensure that the design, manufacture and installation of Marine manhole covers meet international standards to ensure the safety of ships and smooth sailing.

The main technical requirements include the following aspects:

Material requirements: Manhole cover should be made of corrosion-resistant, wear-resistant high-quality materials, common materials include carbon steel, stainless steel and so on. Materials shall be selected in accordance with relevant classification society regulations. According to CB/T 19-2001 standard, the main parts of Marine manhole cover materials are shown in the following table:

| Name of parts | Materials | ||

| Name | Mark | Standard number | |

Cover plate Coaming plate Seat ring | Hull structure | Class A | GB 721-2000 |

| Stud | Stainless steel | 1Cr18Ni9Ti | GB/T 1220-1992 |

| Nut | Ordinary carbon steel | Q235A | GB/T 700-1988 |

| Orichalcum | HMn58-2 | GB/T 5231-2001 | |

| Stainless steel | 1Cr18Ni9Ti | GB/T 1220-1992 | |

| Handle | Ordinary carbon steel | Q235-A | GB/T 700-1988 |

| Gasket | Oil-resistant rubber (edible rubber for drinking water tanks) | GB/T 5574-1994 (HG 2944-1997) | |

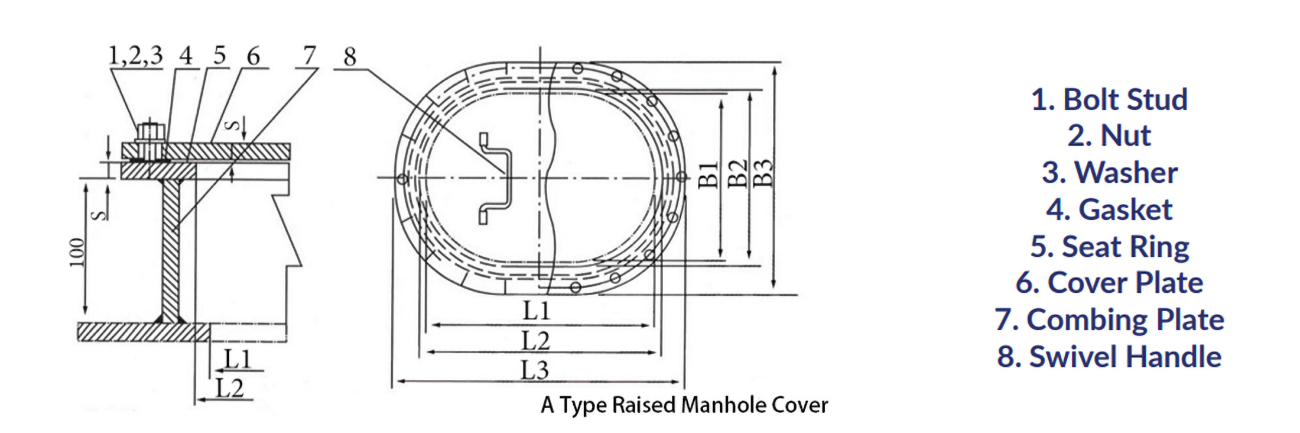

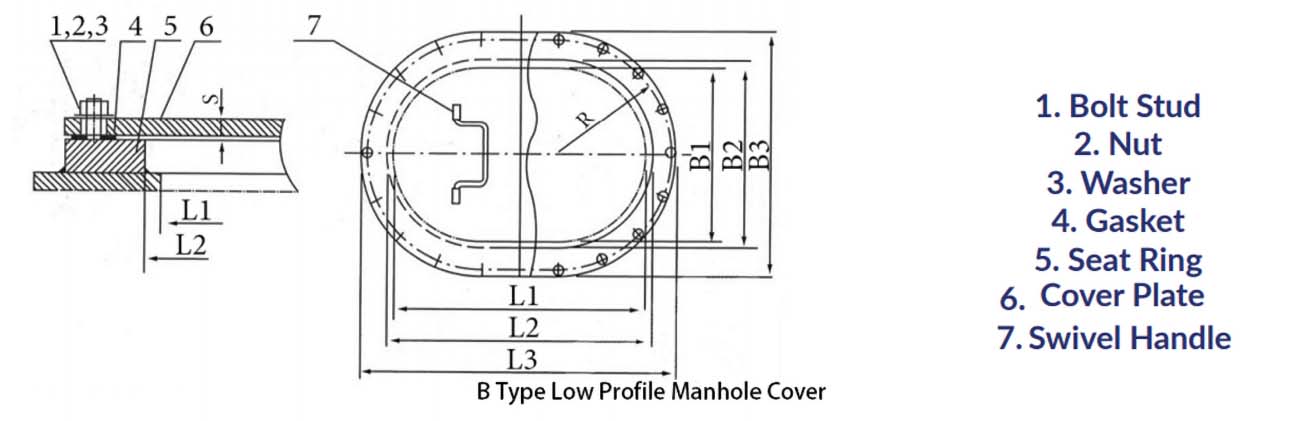

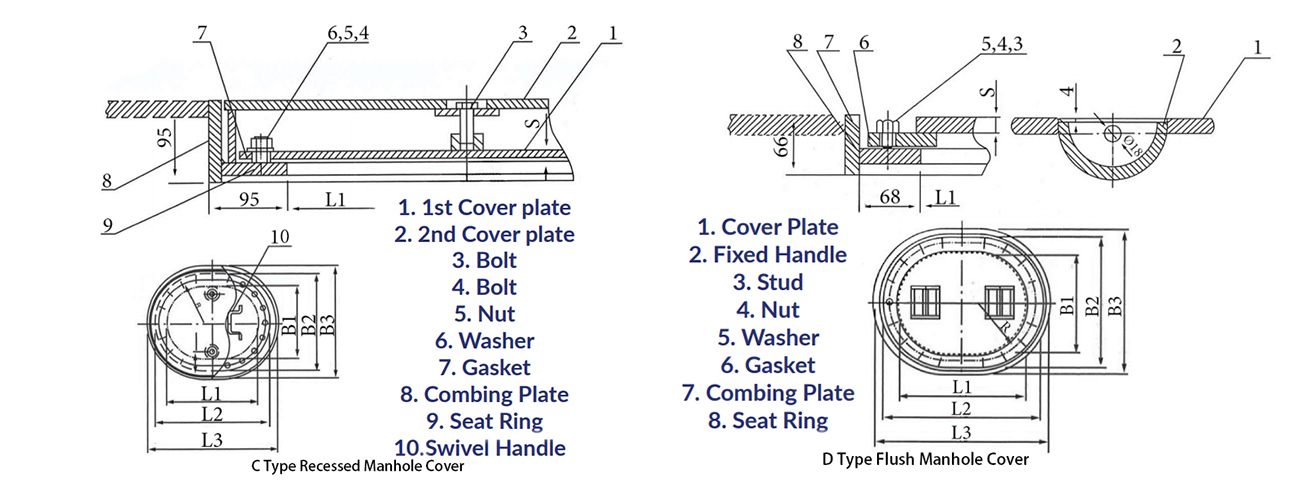

Structural design: The structural design of the manhole cover should take into account the complex environment of the ship in the navigation, with sufficient strength and stability, and can withstand the external forces such as ship movement and wave impact. According to CB/T 19-2001 standard, the structure of Marine manhole cover is as follows:

Outline structure:

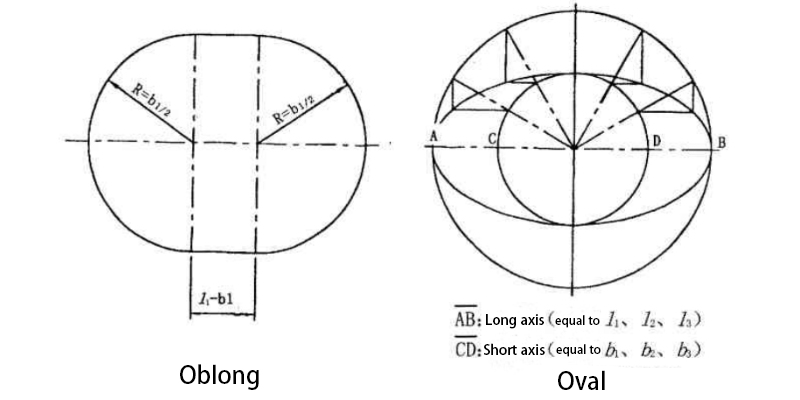

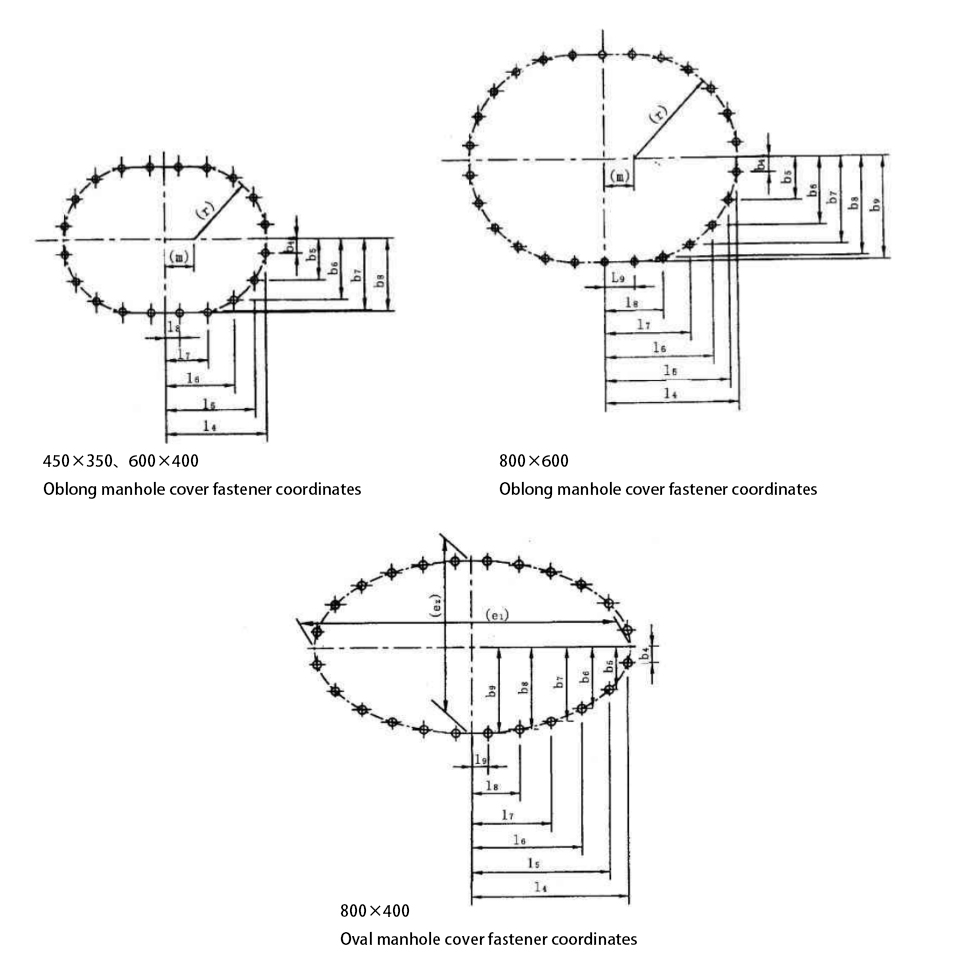

Geometric drawings of oblongs and oval:

Fasteners for Marine manhole covers:

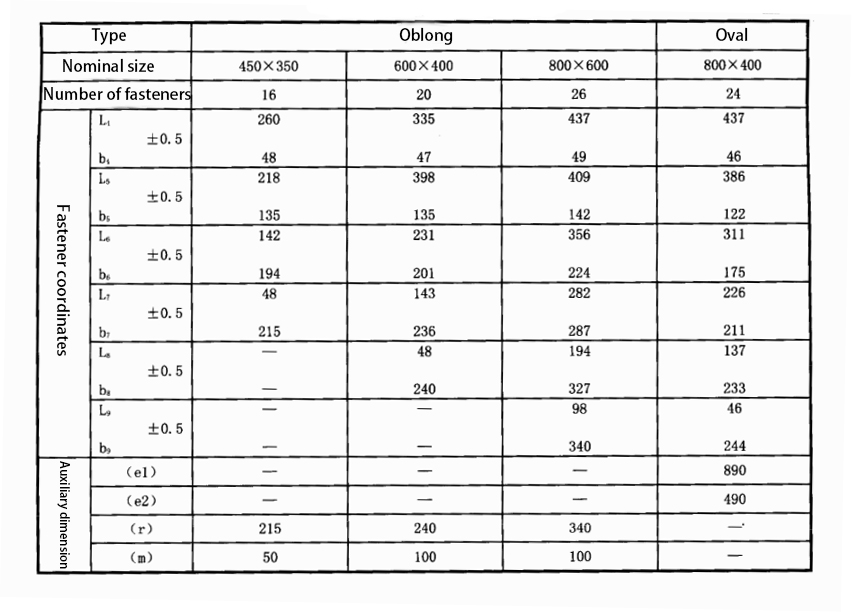

Fasteners for Marine manhole covers are the key components to ensure the safety, sealing and stability of manhole covers. The following is the fastener coordinates and quantity:

Fastener coordinate size and quantity:

Sealing property:

Rubber gasket: tensile strength is not less than 7.84MPa; elongation is not less than 300%; the permanent deformation is not more than 25%; shore hardness 60Sh~75Sh; operating temperature range -30℃~100 ℃. The drinking water tank shall be made of rubber that meets the requirements of dietary hygiene.

Welding: The welds of the seat ring, cover plate and coaming should ensure sufficient strength and tightness.

Flatness deviation: The flatness deviation of the sealing surface between the cover plate of the manhole cover and the seat ring is not more than 1mm.