Spring applied Brakes for Marine Winch

Spring applied brakes are commonly used in marine winches to provide reliable braking and holding capabilities. These brakes are designed to automatically engage when power is removed or in the event of a power failure, ensuring that the winch is securely held in place. The spring-applied brakes work by using springs to apply pressure to the brake pads, which then clamp down on the brake disc or drum to stop the rotation of the winch. This type of brake is ideal for marine winches as it provides a fail-safe braking system that can prevent accidents and damage to equipment.

Overview

Spring applied Brakes for Marine Winch

A manually operated spring applied brake is shown in figure 1. When tightening the brake screw, the spring is compressed and the compression is proportional to the holding load of the brake. When the brake is tested and adjusted to the correct rendering force, an indicator is adjusted so that the brake can be reset repeatedly to its correct value. This type of spring applied brake setting indicator compensates fully for any wear of the brake lining and elongation in the brake mechanism.

Figure 1: Spring applied broke with manual setting

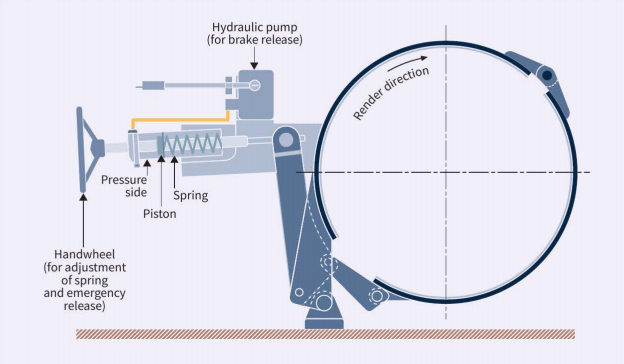

A spring applied band brake with hydraulic release is shown in figure 2. In the case shown, the brake is released by a hydraulic hand pump. To apply the brake, a valve is opened to release the hydraulic pressure. Winches with hydraulic drives can use the main hydraulic pressure to release the brake.

The handwheel is not used for routine operation. It is used to adjust the spring compression during calibration and to release the brake in case of a hydraulic malfunction. The handwheel should be secured with a seal after each calibration to prevent tampering. Alternatively, the brake screw can be equipped with a brake setting indicator to provide an easy visual check of the correct adjustment of the brake setting.

Figure 2: Spring applied brake with hydraulic release

For more marine winch information, kindly please click here.