Ship side Butterfly Valve

Ship side Butterfly Valve is mainly composed of valve body, valve plate, bearing, clamping clip, sealing ring and so on. Connection: conform to ANSI, GB, JIS, DIN. Adopt ISO5211 platform design for direct mounting of actuator. Ship side Butterfly Valve is widely used in water supply, sewage treatment, gray water and other pipelines, its role is to control the flow of media in the pipeline, to prevent backflow. Ship side Butterfly Valve mounting method of the butt-clamp butterfly valve is flange clamping, in the installation, only need to use bolts to clamp the valve with the pipeline, no need for flange connection, easy maintenance and replacement.

Overview

Features:

Effectively reduces the possibility of stem blowout under internal pressure; at the same time, protects the integrity and strength of the stem and avoids deformation and fracture due to torque during use.

When the valve is completely closed the seat sealing convex surface is deformed backward, better extrusion strength and better sealing performance. When the valve is open, opening is easier because there is no buildup in front of the valve plate sealing surface. The spherical sealing surface design reduces torque and extends sealing life.

Raw rubber, fatigue resistant and soft. No need for synthetic and recycled rubber. Concave-convex design ensures that the torque of the butterfly valve is equal before and after installation, which will not cause the valve not to open or close in use due to the deformation of the valve seat during connection; Seat reinforcing rib, the fitting surface with the valve body is designed with a locating reinforcing rib, which will not displace the seat when the valve plate is closed at 0°, and increase the pulling up capacity.

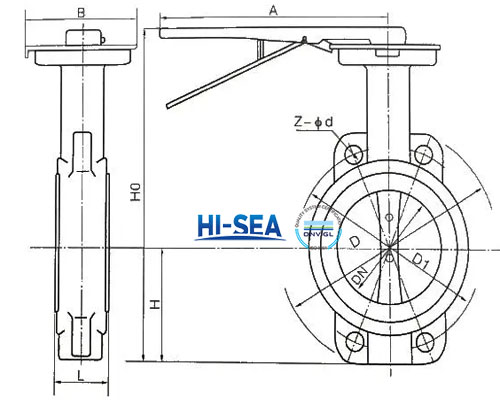

Drawing:

Picture: