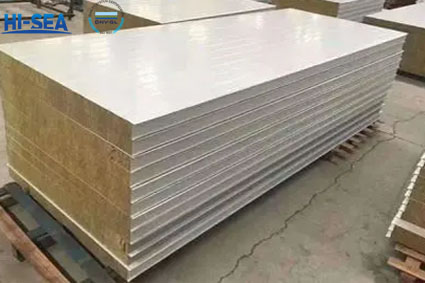

Rock Wool Wall Panel

The selection of fireproof materials for ship interiors should comply with the standards of the International Maritime Organization (IMO)

Rock wool panels are kinds of heat-insulating and fireproof material made of natural basalt or man-made rock, which is characterized by high temperature resistance, fireproof and flame retardant, sound insulation, heat preservation and environmental protection. As it is a natural and harmless material with a long service life, it is also more common in ship interiors.

Overview

Technique:

1. Put a certain amount of basalt slag in the high melting furnace, fully melted to change the physical structure of the natural ore, to create the structural foundation of the rock wool board.

2. Basalt slag after high-temperature melting treatment, the raw material will become soft, this time the use of high-speed centrifugal machine to deal with it, the melted slag will gradually form a filamentous material, slowly rotating, all the flinging silk all fit together after the inorganic cotton, after the process of making rock wool flocculent cotton.

3. Just made out of the shape of the inorganic cotton is not fixed, need to use high-speed blower, the use of wind to take away the heat from the surface of the inorganic cotton, so that it is easier to mold.

4. Add high efficient water enhancer and binder into the inorganic cotton, so that it has the role of preventing water penetration and higher strength and hardness.

Picture:

Model | Thickness | Fire Class | Core Material | Remark |

B50A | 50mm | B-15 | Rock Wool | |

B30A | 30mm | B-15 | Rock Wool | |

B25A | 25mm | B-15 | Rock Wool | |

B25AXY | 25mm | B-0 | Rock Wool | Noise Reduction Panel |

B25AL | 25mm | B-15 | Aluminum Honeycomb | |

B50AD | 50mm | B-15 | Rock Wool | Cable Panel |

BAGD | 50mm | B-15 | Rock Wool | High Sound Reduction Panel |

B25A+ B25A | ≥70mm | B-15 | Rock Wool |