Polymer Bearing

Polymer Marine bearing is a kind of modified polymer material. It has particularly excellent friction and wear characteristics of water-oil lubrication and high physical and mechanical properties.

The polymer bearings mainly include rubber materials and plastic materials. The former is a high elastic material with good vibration absorption, which is very suitable for water lubricated bearing materials. The polymer plastic bearing is light weight, corrosion resistant and easy to make.

Polymer bearing can be used in seawater, river water and sewage, and can be used as materials for bearings, bushings, supporting sliders, gears, rollers, etc. It can applied in electrolytes such as weak acid, alkali and salt water but will not be corroded.

Overview

The polymer bearing has good lubricity and stability as well as low friction coefficient, suitable for all kinds of marine bearings on ships. It is superior to traditional bearing materials mainly in excellent physical, chemical and mechanical properties. It especially features the good chemical stability and good self-lubricity and low friction coefficient

Features:

Wear resistant and corrosion resistant

Easy water/oil lubrication performance

Low water swelling coefficient, no oil swelling

Easy installation and processing

Strong tenacity and durability

Wide application and operating temperature range

Impact load resistance

Wide operating temperature range

Higher PV values

Harmless to humans

Thanks to its good comprehensive mechanical properties, polymer bearings are widely used in: water/oil lubricated stern tube bearings, water/oil lubricated rudder bearings, oil lubricated intermediate bearings. It is also popular for adjustable pitch propeller: pitch slider, deck machinery (oil lubricated or grease lubricated).

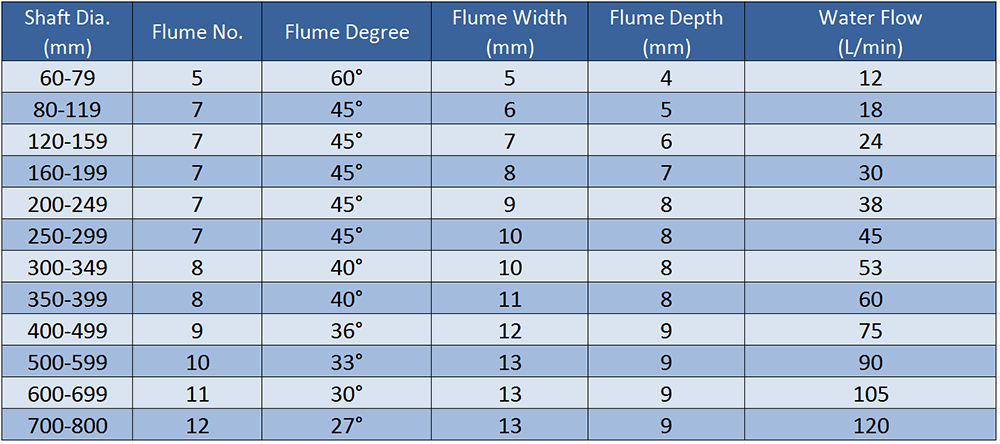

Main Technical Parameters of Polymer Bearing