Mooring Wire Ropes

In moorings, steel wire rope can be used for motion control, station keeping, and vessel positioning and son on. Steel wire ropes are used on a wide variety of ship types and sizes. Compared to chain, steel wire rope easier to install and lighter on the floating construction. Steel wire ropes have a high strength-to-diameter ratio and excellent resistance to abrasion and other forms of mechanical damage.

Overview

Diameter: 52~160mm

Provide various Class Certificate: CCS, ABS, DNV, RMRS, BV, LR, etc.

Material:

high quality, high tensile, drawn galvanized wire is recommended for wire mooring lines. Other steel materials and processing methods may include high carbon steel, ungalvanized steel, stainless steel, aluminium/ zinc coatings and hot dip galvanizing.

Construction:

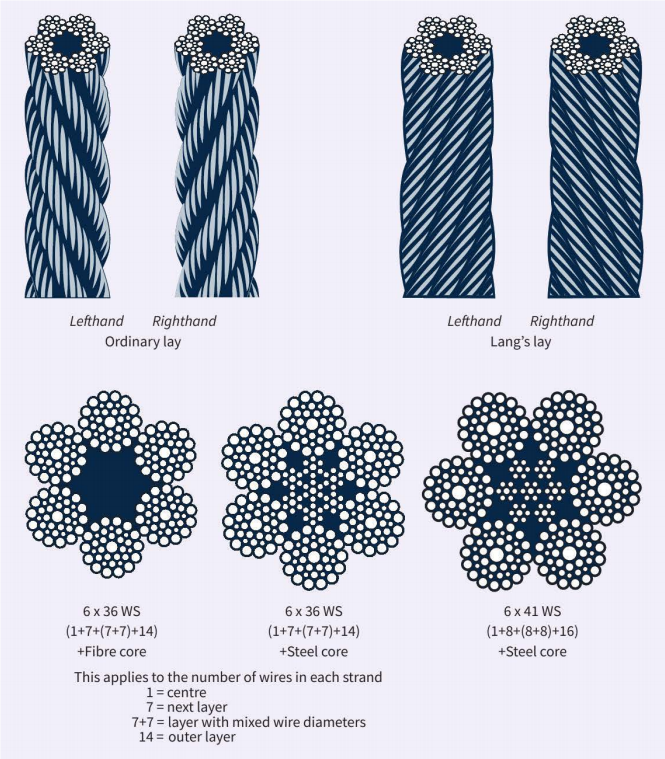

6 x 36 or 6 x 41 (6 x 36 class) wire construction is recommended for all general mooring line applications with the wires in each strand of equal lay and the strands of regular (ordinary) right hand lay. Figure 1 shows the recommended wire construction.

Factors influencing performance

The key factors influencing performance of steel wire mooring lines are strength, bend fatigue, tensile fatigue, crushing and deformation, corrosion and abrasion, and temperature.

1. Strength:

Tensile strength of new steel wire mooring lines is recommended to use wire with minimum tensile strengths ranging from 1,770 to 2,160N/ mm2. Pre-formed, galvanised drawn wire with these tensile grades is now widely available and is recommended in place of ungalvanised wire grades.

2. Bend fatigue and D/d ratio:

As with all rope, steel wire will lose strength when bent over a radius. A fibre core rope will lose more strength at a given bend ratio than an IWRC rope. It is therefore recommended that fibre cored steel wire ropes are not used.

A minimum bend ratio (D/d) of 15 is recommended.

3. Fatigue and abrasion:

Fatigue in wire mooring lines is mainly caused by the wires being bent over a winch drum, sheaves or deck fairleads. A wire constructed with big outer wire strands, e.g. a 6 x 19 construction, will have less resistance to bending fatigue than a wire with smaller wire strands, e.g. a 6 x 36 construction.

Abrasion to wire can be caused when it runs over deck fittings or when it rubs against itself when spooled on and off the winch drum.

Specifications and procurement

There are currently no international standards for the specification of steel wire ropes specifically for use as ship mooring lines. 6 x 36 class wire is suitable for most mooring line applications. When ordering steel wire ropes it is good practice to give as much application and background information as possible. It is recommended that replacement lines match the performance of the existing lines and are compatible with the mooring design.