Marine Watermakers

The main function of marine watermakers is to provide abundant fresh water resources for ships. During long voyages at sea, the daily life water for crew members, the cooling and cleaning water for ship equipment, etc., all require a stable supply of fresh water. Especially in cases such as ocean voyages, scientific expeditions, and military applications, ensuring a reliable supply of fresh water resources is particularly crucial.

Marine watermakers generally apply the principle of reverse osmosis. Pretreated seawater passes through the reverse osmosis membrane under the pressurization of a high-pressure pump. The reverse osmosis membrane is selective, only allowing water molecules to pass through and blocking salts, impurities, microorganisms, etc. in the seawater on the other side of the membrane to obtain fresh water. During this process, the pretreatment stage includes operations such as removing suspended substances, organic matter, and microorganisms in the seawater, as well as adjusting the pH value and hardness of the seawater, with the aim of protecting the reverse osmosis membrane and enhancing the desalination effect.

As professional suppliers of ship equipment, we have rich experience in the field of ship auxiliaries and can provide you with professional and effective solutions. Email: <hs10@cqhisea.com>

Overview

Product Introduction

The main methods of seawater desalination are distillation and reverse osmosis. Reverse osmosis is widely used, has low energy consumption and a high desalination rate.

The marine water maker adopts the best quality seawater reverse osmosis membrane in the world, with a high desalination rate, stable performance, safety and reliability.

The high-pressure pump adopts international brands and is equipped with high and low pressure protection devices to ensure the safety and reliability of the equipment.

The treated water quality complies with the water quality standards of China's national drinking water and can be drunk directly, with a sweet taste.

Product Features

High-quality quartz sand filter can remove large particles of impurities, algae, etc. in the water, and can be manually and independently cleaned;

The original imported Dow reverse osmosis membrane for seawater desalination from the United States has a desalination rate of up to 99.7%;

All high-pressure connectors are made of SS316 material, which is safe and anti-corrosive;

Low-pressure pipe fittings are made of high-quality UVPC pipe fittings;

High-quality SS316L high-pressure pump is safe, anti-corrosive and operates stably;

Ultraviolet online sterilization at the end of water production to ensure the water quality of the effluent.

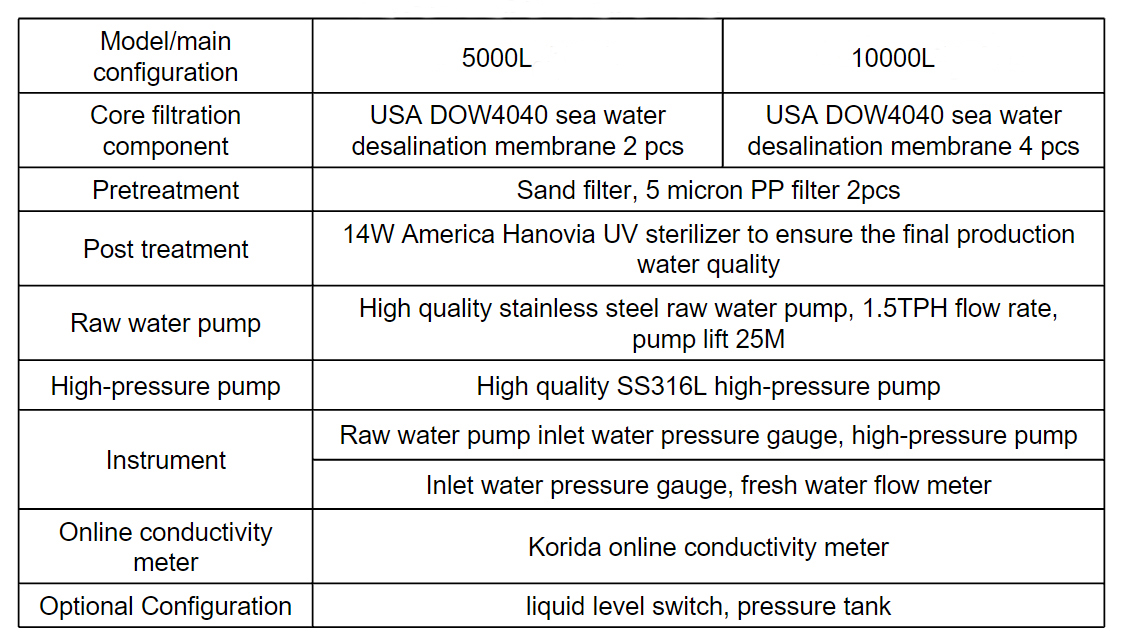

Main Configuration

Consumable replacement cycle:

1. Quartz sand: about one year;

2. 5 micron PP filter : about 3 months;

3. USA DOW RO membrane: about 3 years.

Note:the premise of calculation of above replacement cycle is on the basis of satisfying the use and maintenance condition of this equipment, running 20 hours per day.

Conclusion

Thank you for browsing through the entire text. I hope you have gained a certain understanding of the Marine Watermakers. If you have purchasing needs in related aspects, you can visit the homepage of our seawater desalination plant to learn about it, or contact us directly!